Flexible freeze-thaw resistance treatment method for highway bridge expansion joints in seasonal frozen soil region

A technology for highways and treatment methods, which is applied to bridges, bridge parts, bridge maintenance, etc., can solve the problems of highway bridge expansion joint damage and poor maintenance effects, and achieve the goals of preventing water seepage and soil leakage, simple technology, and improved anchorage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

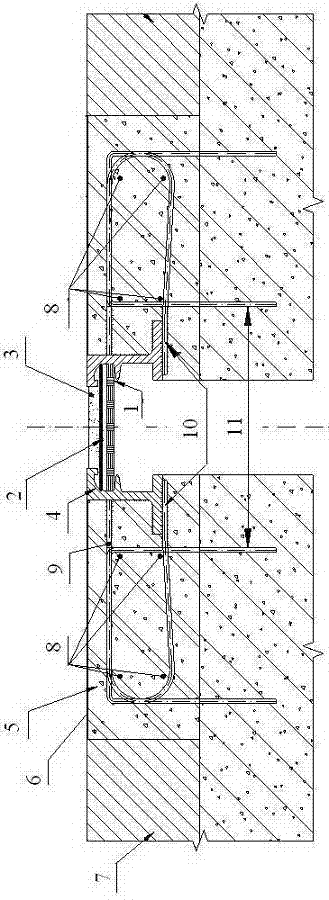

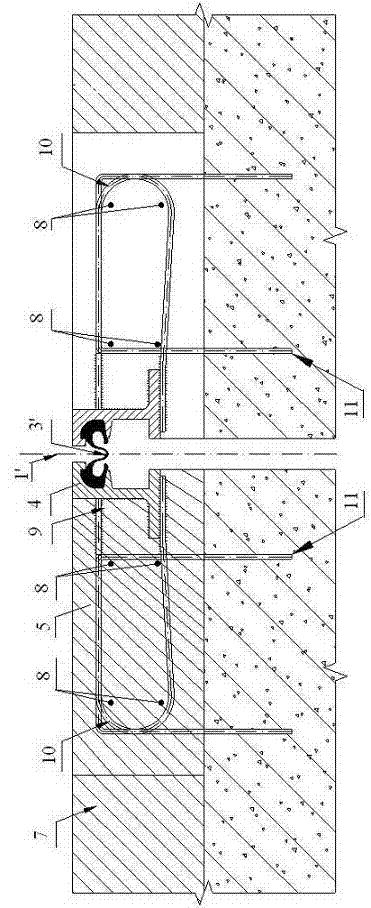

Image

Examples

Embodiment 1

[0069] Include the following steps:

[0070] 1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5,

[0071] The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0072] Universal Portland cement PO42.5 700 parts,

[0073] Medium coarse sand 2000 parts,

[0074] 2000 stones,

[0075] 300 parts of water,

[0076] The composite material comprises the following raw materials in parts by weight:

[0077] Polycarboxylate superplasticizer 60 parts,

[0078] 0.03 parts of air-entraining agent,

[0079] Silicone resin polyether emulsion 0.02 parts

[0080] Mortar Mate 2 parts,

[0081] (2) Flexible filling material between the expansion joints of side beams

[0082] (1) Use a steel wire brush to brush the liquid steel surface derusting and phosphating agent between the Mauler expansion joints of the side beams, derusting and p...

Embodiment 2

[0114] Include the following steps:

[0115] 1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5,

[0116] The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0117] General Portland cement PO42.5 850 parts,

[0118] Fly ash Class I 150 parts,

[0119] 5 parts of ternary copolymer fiber,

[0120] Silica fume, SiO2 content greater than 90%, specific surface area between 13,000 square meters / kg and 20,000 square meters / kg 50 parts,

[0121] Medium coarse sand 2500 parts,

[0122] 2650 stones,

[0123] 380 parts of water,

[0124] The composite material comprises the following raw materials in parts by weight:

[0125] Polycarboxylate superplasticizer 105 parts,

[0126] 1.52 parts of air-entraining agent,

[0127] Silicone resin polyether emulsion 2.01 parts,

[0128] Low-viscosity thickening plasticizer, viscosit...

Embodiment 3

[0165] Include the following steps:

[0166] 1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5,

[0167] The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0168] Universal Portland cement PO42.5 1000 parts,

[0169] Fly ash Class I 300 parts,

[0170] 10 parts of ternary copolymer fiber,

[0171] Silica fume, SiO2 content greater than 90%, specific surface area between 13,000 square meters / kg and 20,000 square meters / kg 100 parts,

[0172] Medium coarse sand 3000 parts,

[0173] 3300 stones,

[0174] 460 parts of water,

[0175] The composite material comprises the following raw materials in parts by weight:

[0176] Polycarboxylate superplasticizer 150 parts,

[0177] Air-entraining agent 3 parts,

[0178] Silicone polyether emulsion 4 parts,

[0179] Low-viscosity thickening plasticizer, viscosity is 50~10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com