Plastic waterproof plate and preparation method therefor

A waterproof board and plastic technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of the modified asphalt waterproof board is too hard, low welding strength, etc., to achieve excellent flexibility, excellent aging resistance, wear resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

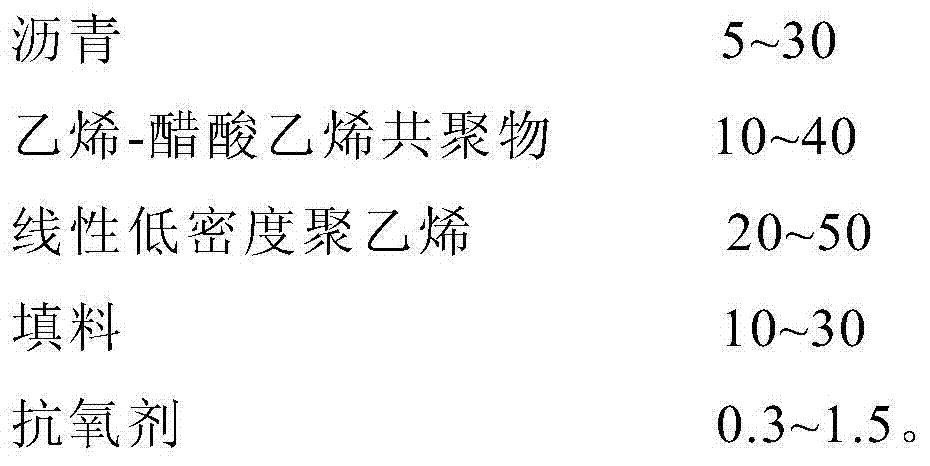

[0031] A plastic waterproof board is made of the following raw materials in parts by mass:

[0032]

[0033] Wherein, the mass content of vinyl acetate in the ethylene-vinyl acetate copolymer used is 5%, the melt index of linear low density polyethylene is 0.5g / 10min, the asphalt is No. 10 construction petroleum asphalt, and the main component of antioxidant 1010 is four [Methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

[0034] And the preparation technology of above plastic waterproof board comprises the following steps:

[0035] (1) Ingredients: take the raw materials by the above-mentioned parts by mass;

[0036] (2) Mixing: Add the above raw materials into a high-speed mixer for stirring, the temperature is 70±10°C, the mixing time is 15 minutes, and the stirring speed is 20 rpm;

[0037] (3) Blending extrusion: Blending extrusion is carried out with a twin-screw extruder. The temperatures of the screws of the twin-screw extruder in the f...

Embodiment 2

[0045] A plastic waterproof board is made of the following raw materials in parts by mass:

[0046]

[0047] Among them, the mass content of vinyl acetate in the ethylene-vinyl acetate copolymer used is 30%, the melt index of linear low density polyethylene is 2.0g / 10min, the asphalt is No. 10 construction petroleum asphalt, and the main component of antioxidant 1076 is β -(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, the main component of antioxidant 168 is tris[2.4-di-tert-butylphenyl]phosphite.

[0048] And the preparation technology of above plastic waterproof board comprises the following steps:

[0049] (1) Ingredients: take the raw materials by the above-mentioned parts by mass;

[0050] (2) Mixing: Add the above raw materials into a high-speed mixer for stirring, the temperature is 70±10°C, the mixing time is 15 minutes, and the stirring speed is 10 rpm;

[0051] (3) Blending extrusion: Blending extrusion is carried out with a twin-screw extruder. Th...

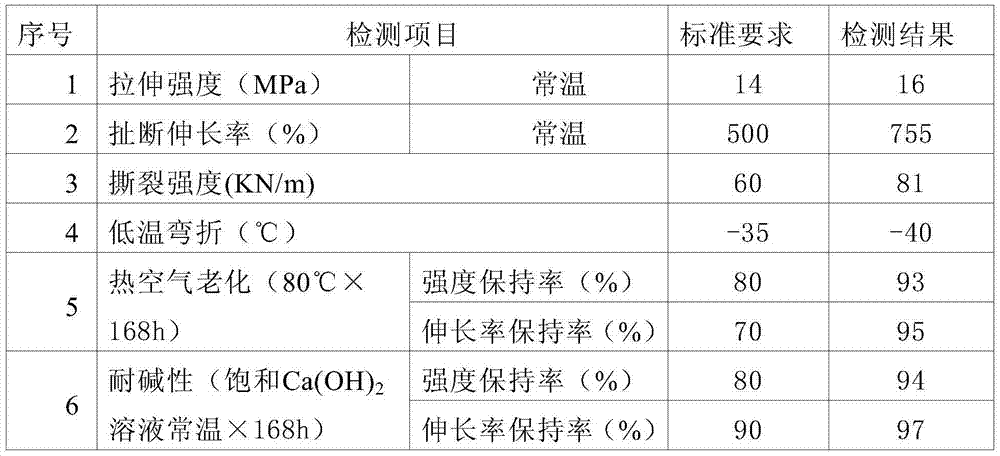

Embodiment 3

[0059] A plastic waterproof board is made of the following raw materials in parts by mass:

[0060]

[0061]

[0062] Wherein, the mass content of vinyl acetate in the ethylene-vinyl acetate copolymer used is 20%, the melt index of linear low density polyethylene is 3.0g / 10min, the asphalt is No. 60 road petroleum asphalt, and the main component of antioxidant 1010 is four [Methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

[0063] And the preparation technology of above plastic waterproof board comprises the following steps:

[0064] (1) Ingredients: take the raw materials by the above-mentioned parts by mass;

[0065] (2) Mixing: add the above raw materials into a high-speed mixer for stirring, the temperature is 70±10°C, the mixing time is 10 minutes, and the stirring speed is 5 rpm;

[0066] (3) Blending extrusion: Blending extrusion is carried out with a twin-screw extruder. The temperatures of the screws of the twin-screw extruder in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com