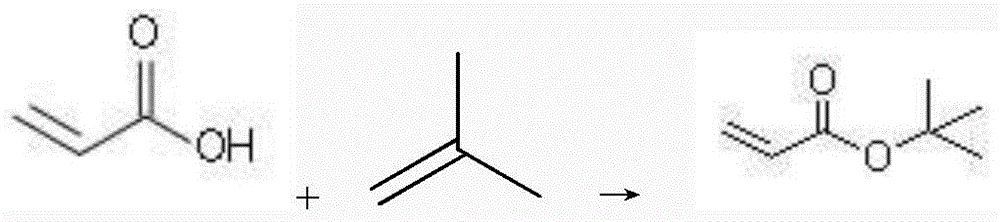

A kind of technique of catalytically synthesizing tert-butyl acrylate

A technology of tert-butyl acrylate and acrylic acid, which is applied in the field of catalytic synthesis of tert-butyl acrylate, can solve the problems of catalyst performance decline, increase the cost of tert-butyl acrylate preparation, poor catalyst reuse, etc., and achieve high raw material utilization and excellent quality Low-temperature reactivity, selectivity, and excellent reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Following examples or comparative examples relate to nanometer solid superacid SO 4 2- / SnO 2 The preparation method comprises the steps:

[0030] (1) Nano-SnO 2 Preparation: under the condition of vigorous stirring, 0.15mol / L of SnCl 4 The solution is added dropwise to 2.5% ammonia water containing a dispersant polyethylene glycol, and the pH of the solution is kept at about 9. After the dropwise addition, Sn(OH) was obtained 4 sol, aged in a water bath at 70°C for 10 h to obtain SnO 2 gel. Wash thoroughly with distilled water until Cl-free - , vacuum filtration. The resulting filter cake was replaced with n-butanol for moisture. Disperse the filter cake in 10 times of n-butanol, stir and mix it and carry out azeotropic distillation. When the temperature reaches the water-n-butanol azeotropic temperature of 92.4°C, the water molecules in the colloid will be removed in the form of azeotrope , as the distillation proceeds, the temperature of the system graduall...

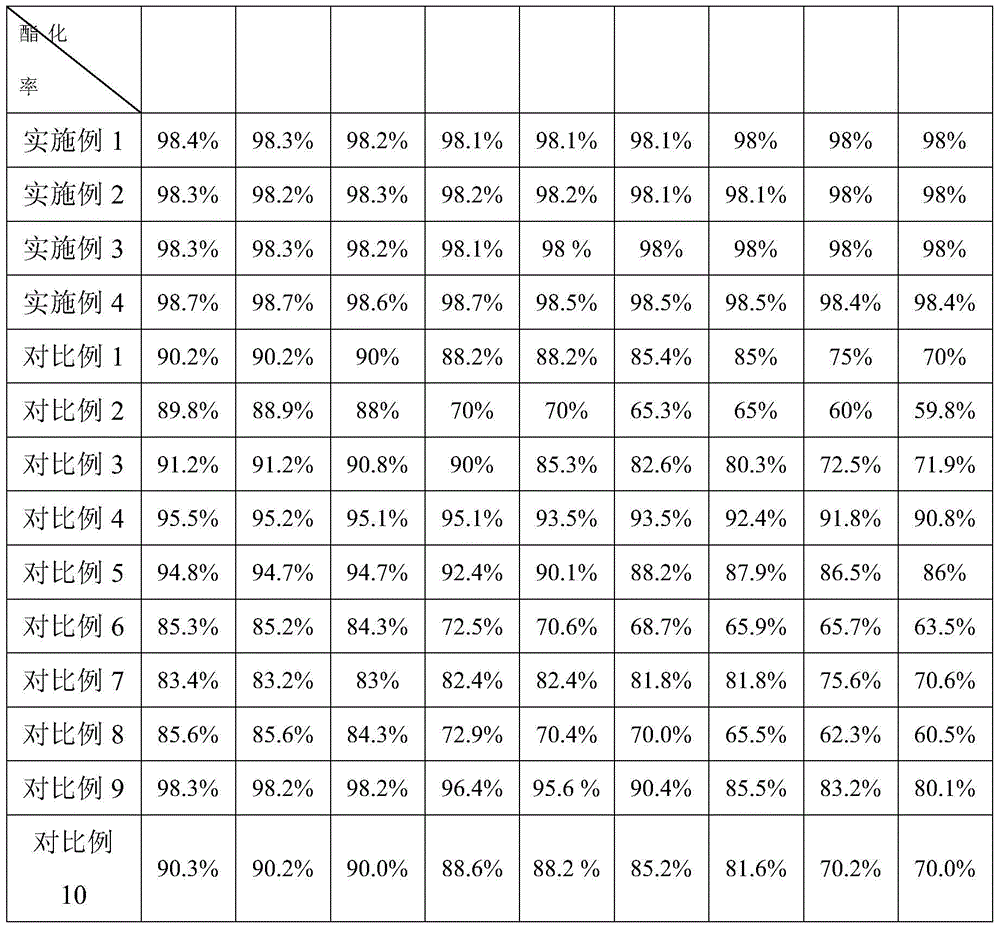

Embodiment 1

[0033] A kind of preparation technology that catalyzes the synthesis of tert-butyl acrylate with strong acidic cation exchange resin combination product as catalyst, carries out successively according to the following steps:

[0034] 1) acrylic acid, made of nano-solid superacid SO 4 2- / SnO 2 , strong acidic cation exchange resin A, strong acidic cation exchange resin B and strong acidic cation exchange resin C catalyst composition, polymerization inhibitor A, polymerization inhibitor B are added in the airtight reaction kettle, and the isobutylene of liquefaction is added dropwise to carry out Esterification reaction;

[0035] 2) After the dropwise addition is completed, keep warm;

[0036] 3) After the heat preservation is completed, the closed reaction kettle is depressurized, filtered, and the liquid components are extracted into the rectification tower;

[0037] 4) sequentially separate by-product tert-butyl alcohol, diisobutylene and target product tert-butyl acryla...

Embodiment 2

[0044] A kind of preparation technology that catalyzes the synthesis of tert-butyl acrylate with strong acidic cation exchange resin combination product as catalyst, carries out successively according to the following steps:

[0045] 1) acrylic acid, made of nano-solid superacid SO 4 2- / SnO 2 , strong acidic cation exchange resin A, strong acidic cation exchange resin B and strong acidic cation exchange resin C catalyst composition, polymerization inhibitor A, polymerization inhibitor B are added in the airtight reaction kettle, and the isobutylene of liquefaction is added dropwise to carry out Esterification reaction;

[0046] 2) After the dropwise addition is completed, keep warm;

[0047] 3) After the heat preservation is completed, the closed reaction kettle is depressurized, filtered, and the liquid components are extracted into the rectification tower;

[0048] 4) sequentially separate by-product tert-butyl alcohol, diisobutylene and target product tert-butyl acryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com