Composite fluorine removal agent and preparation method

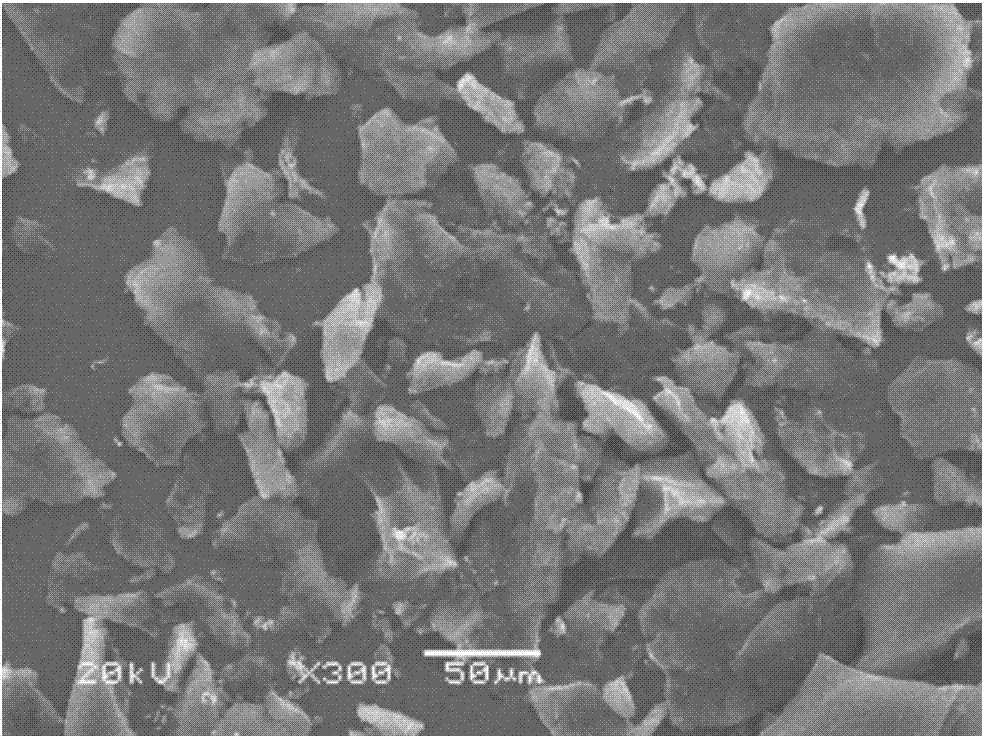

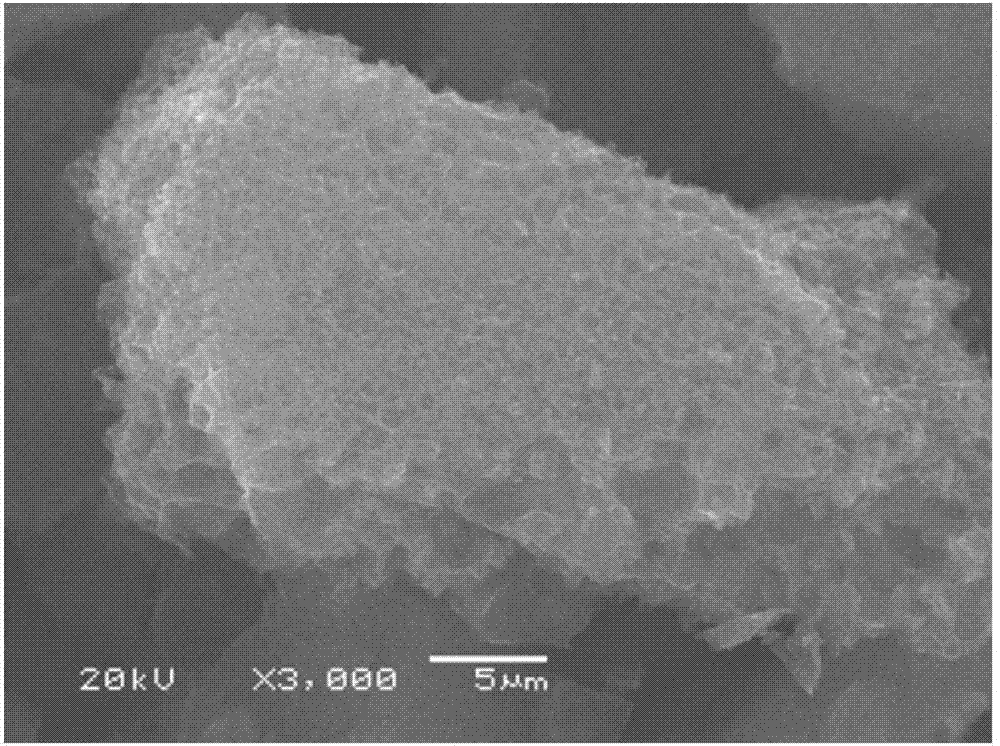

A technology for removing fluorine and pore-forming agent, applied in the field of fluorine-removing agent, can solve the problems of high price of rare earth metal salts, difficult technical operation, high cost of fluorine-removing materials, and achieve improved stability and utilization, liquid The effect of good passability and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

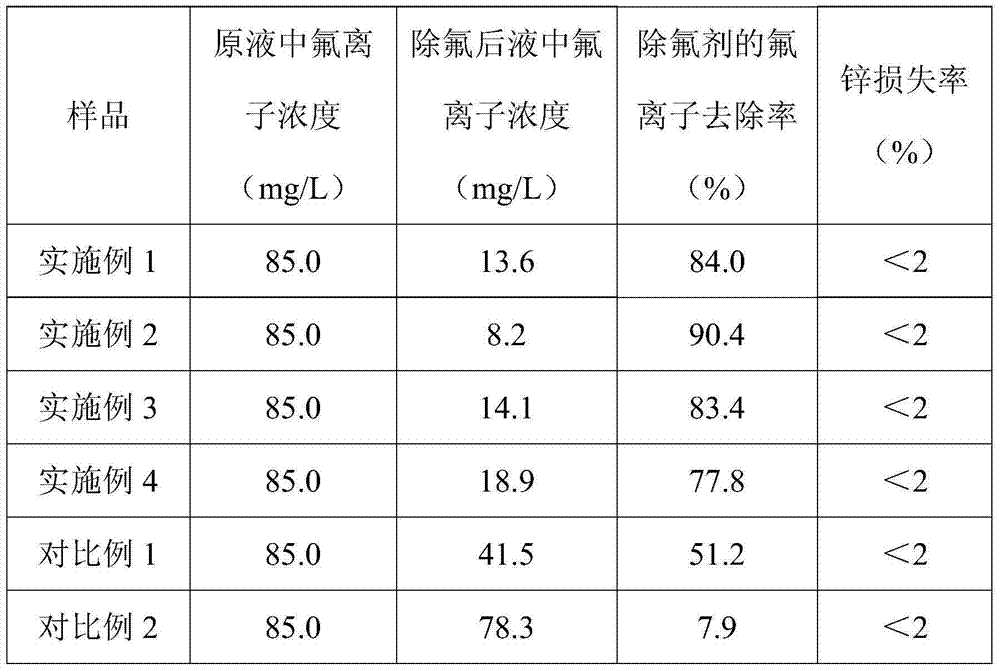

Examples

Embodiment 1

[0036] 1. Preparation of composite defluorinating agent

[0037] 1. Selection of active particle raw materials: select MgCO 3 The mass percent is 92% magnesite, crushed, passed through a 325 mesh sieve, and the undersieve is taken as the mineral particles for preparing the precursor;

[0038] 2. Precursor preparation: mix the mineral particles and asphalt obtained in step 1 in a ratio of 1:1 by weight, then add the materials to the mixed solution of water and ethanol in KOH, and control the weight ratio of asphalt to KOH to 1: 3. After fully mixing, evaporate to dryness at a low temperature of 60°C to obtain a composite defluorinating agent precursor;

[0039] 3. Precursor carbonization: Heat the composite defluorinating agent precursor prepared in step 2 to 400°C at a heating rate of 5°C / min under a nitrogen protective atmosphere, keep the temperature constant for 1 hour, and then press 3°C / min Heating at a heating rate of 750°C, keeping the temperature constant for 2 hours...

Embodiment 2

[0045] 1. Preparation of composite defluorinating agent

[0046] 1. Selection of active particle raw materials: select Al 2 o 3 Bauxite with a mass percentage of 65%, crushed, passed through a 325-mesh sieve, and taking the under-sieve as the mineral particles for preparing the precursor;

[0047] 2. Precursor preparation: mix the mineral particles and asphalt obtained in step 1 in a weight ratio of 2:1, then add the materials to the mixed solution of NaOH in water and ethanol, and control the weight ratio of asphalt to NaOH to 1: 2. After fully mixing, evaporate to dryness at a low temperature of 80°C to obtain a composite defluorinating agent precursor;

[0048] 3. Precursor carbonization: Heat the composite defluorinating agent precursor prepared in step 2 to 300°C at a heating rate of 10°C / min under an argon protective atmosphere, keep the temperature constant for 2 hours, and then press 1°C / min Heating rate of heating to 500°C, constant temperature for 3 hours and then...

Embodiment 3

[0052] 1. Preparation of composite defluorinating agent

[0053] 1. Selection of active particle raw materials: select Al 2 o 3 The mass percentage is 40% kaolin, crushed, passed through a 325 mesh sieve, and the under-sieve is taken as the mineral particles for preparing the precursor;

[0054] 2. Precursor preparation: mix the mineral particles and phenolic resin obtained in step 1 in a ratio of 3:1 by weight, then add the materials to the mixed solution of water and ethanol in KOH, and control the weight ratio of phenolic resin to KOH to 4:1, after fully mixing, evaporate to dryness at a low temperature of 50°C to obtain a composite defluorinating agent precursor;

[0055] 3. Precursor carbonization: heat the composite defluorinating agent precursor prepared in step 2 to 350°C at a heating rate of 6°C / min under an ammonia protective atmosphere, keep the temperature constant for 1 hour, and then press 2°C / min The heating rate was heated to 600°C, and the temperature was k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com