Flip-chip led chip and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unclean etching of deep grooves, unsatisfactory etching uniformity, and increased chip manufacturing costs, etc. The effect of quantum efficiency, good current spreading effect, and good lattice matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

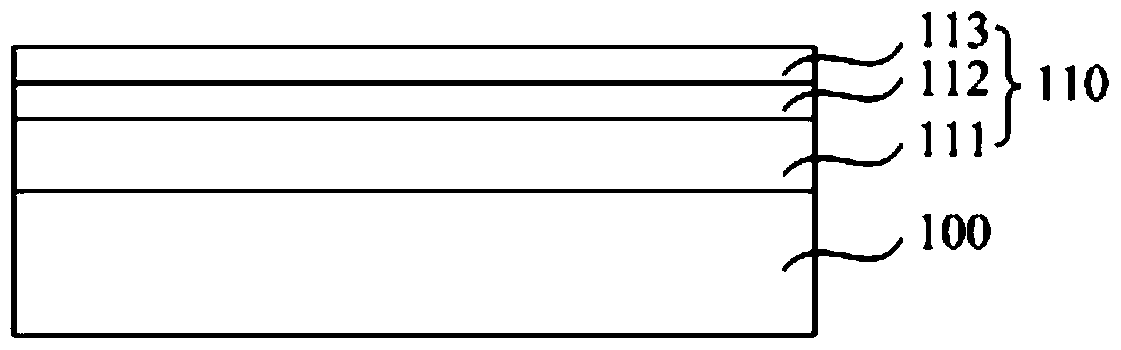

[0063] Such as Figure 1-20 As shown, the flip-chip LED chip includes: a substrate structure 100, an epitaxial layer 110, a contact layer 120, a first connecting electrode 131 and a second connecting electrode 132, an insulating reflective layer 140, a first bonding pad 151 and a second bonding pad Disk 152.

[0064] The substrate structure 100 includes a supporting substrate 101, a lattice matching layer 102, a communication medium layer 103 with periodically arranged columnar structures 103a formed in sequence, and the lattice matching layer 102 is formed on the supporting substrate 101 Above, the communication medium layer 103 is formed on the lattice matching layer 102 and exposes a part of the lattice matching layer 102 .

[0065] The epitaxial layer 110 includes an N-type semiconductor layer 111, an active layer 112, and a P-type semiconductor layer 113 formed in sequence, and the N-type semiconductor layer 111 covers the communication medium layer 103 and the lattice m...

Embodiment 2

[0085] Figure 21 It is a partially enlarged cross-sectional schematic diagram of the substrate structure and the epitaxial layer of the flip-chip LED chip according to the second embodiment of the present invention, Figure 22 It is a partially enlarged top view of the communication medium layer in Embodiment 2 of the present invention.

[0086] Such as Figure 21 with Figure 22 As shown, the difference between this embodiment and Embodiment 1 is that the columnar structure 103a is a columnar protrusion, and the communication medium layer 103 is composed of periodically arranged columnar protrusions, and the crystals are exposed through the gaps between the columnar protrusions. lattice matching layer 102.

[0087] More specifically, the columnar structure 103a is a cylindrical protrusion. Of course, since the supporting substrate 101 is a circular substrate, the columnar structures 103a on the edge of the supporting substrate 101 may be incomplete cylindrical protrusion...

Embodiment 3

[0089] The difference between this embodiment and the first embodiment is that the columnar structure 103a is a polygonal columnar protrusion. Figure 23 It is a partially enlarged top view of the communication medium layer in Embodiment 3 of the present invention. Such as Figure 23 As shown, the columnar structure 103a in this embodiment is a hexagonal columnar protrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com