Liquid steel nitrogen increasing device and method for controlling steel tapping procedures

A tapping process and molten steel technology, applied in the manufacture of converters, etc., can solve the problems of low oxygen content at the end point, long tapping time, and reduced nitrogen absorption of molten steel. The method is simple to operate, reduces the amount of nitrogen added, and has obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Converter steelmaking is divided into processes such as iron loading, smelting, tapping, slag splashing, slag dumping, furnace repairing, empty furnace waiting, etc. The present invention relates to the tapping process of the converter.

[0024] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

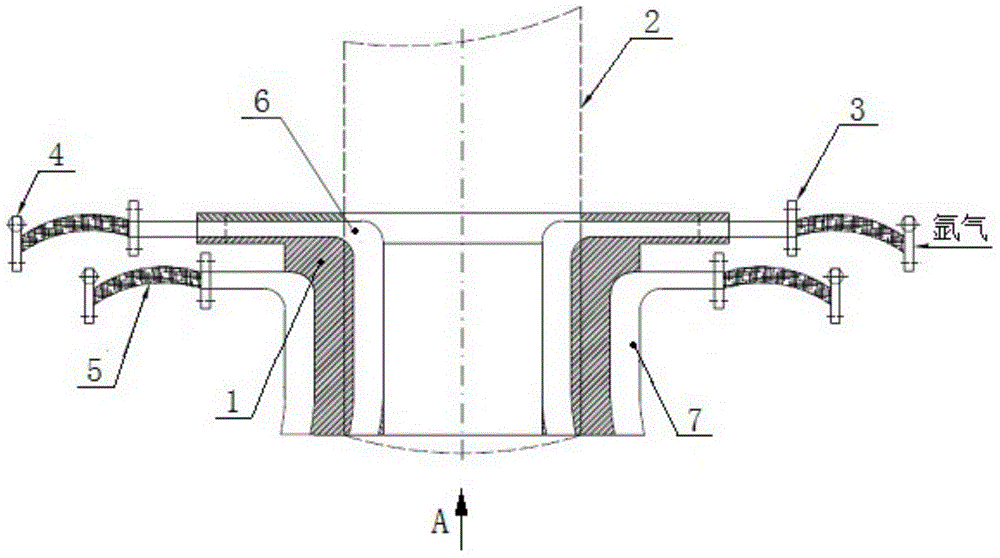

[0025] figure 1 Shown is a schematic diagram of the internal structure of the present invention.

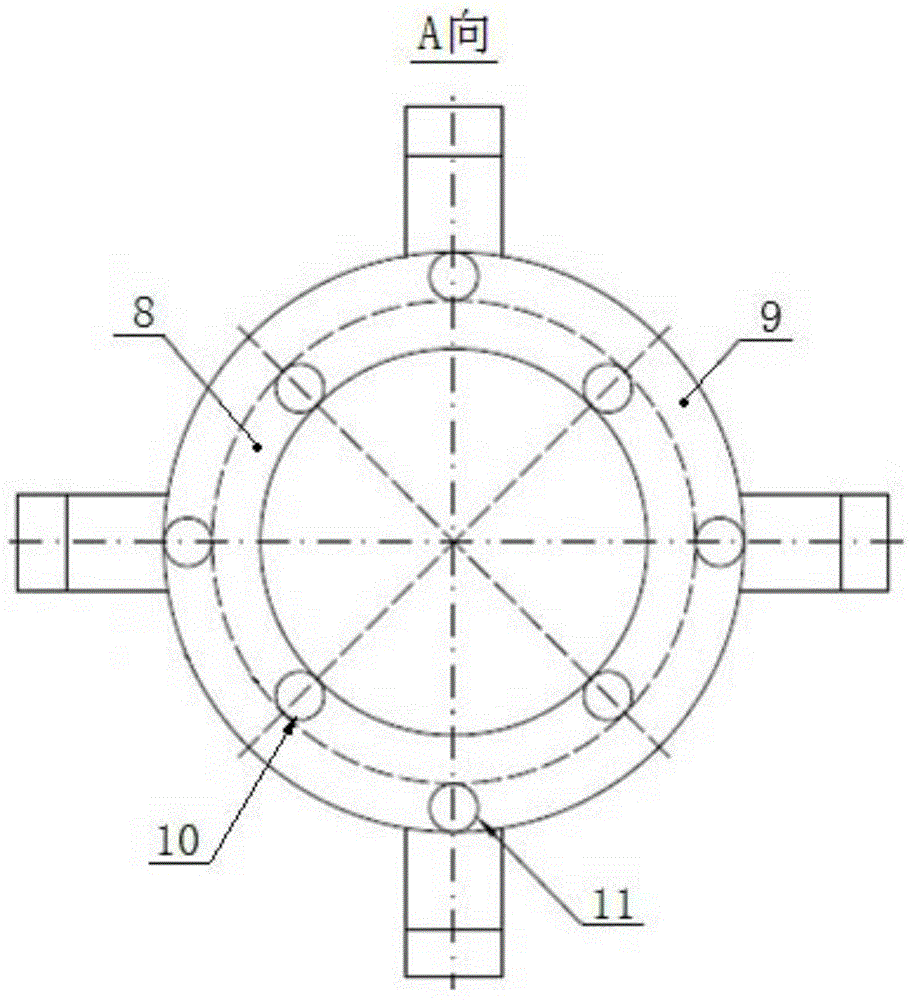

[0026] figure 2 Shown is a schematic top view of the structure of the present invention.

[0027] The invention includes a cylindrical argon plug 1 , an electric cut-off valve 3 and an electric flow regulating valve 4 .

[0028] The cylindrical argon plug 1 is in the shape of a ring column with a cylindrical space in the middle, and the cylindrical argon plug 1 is set on the converter tapping hole 2, and its inner cover and the outer cover of the converter tapping hole 2 form a matching seal On the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com