Bismuth oxide photocatalyst, preparation method and applications thereof

A photocatalyst, bismuth oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve high yield, high uniformity, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

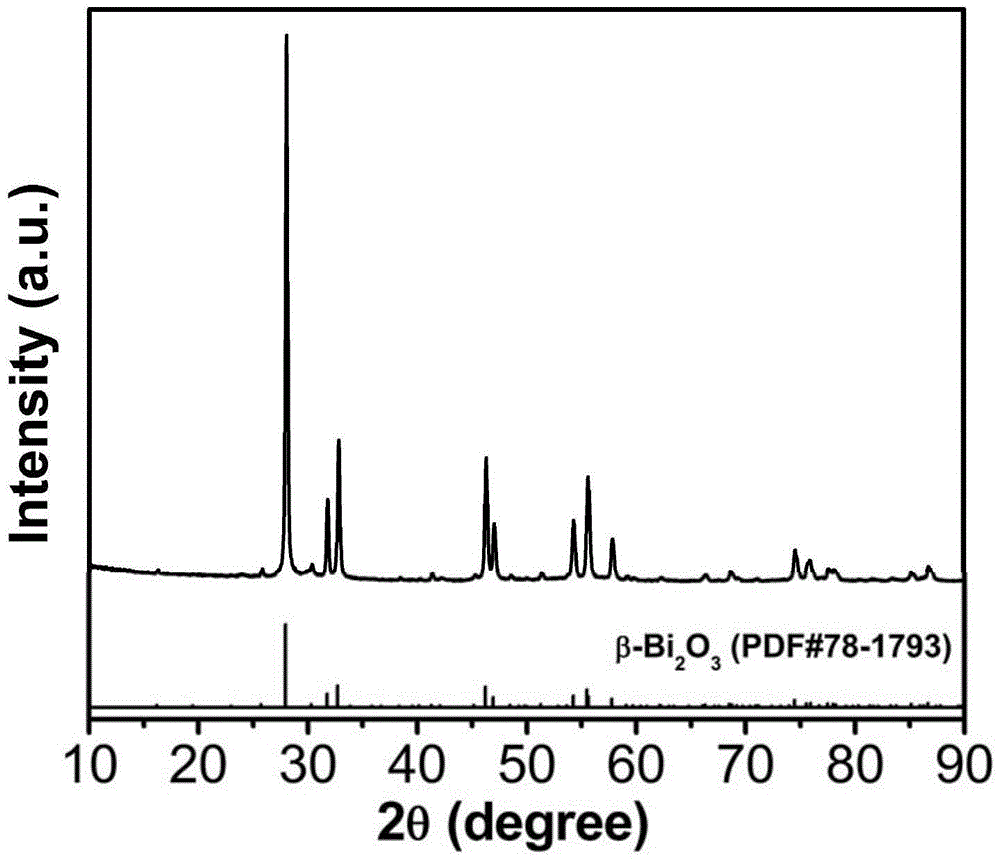

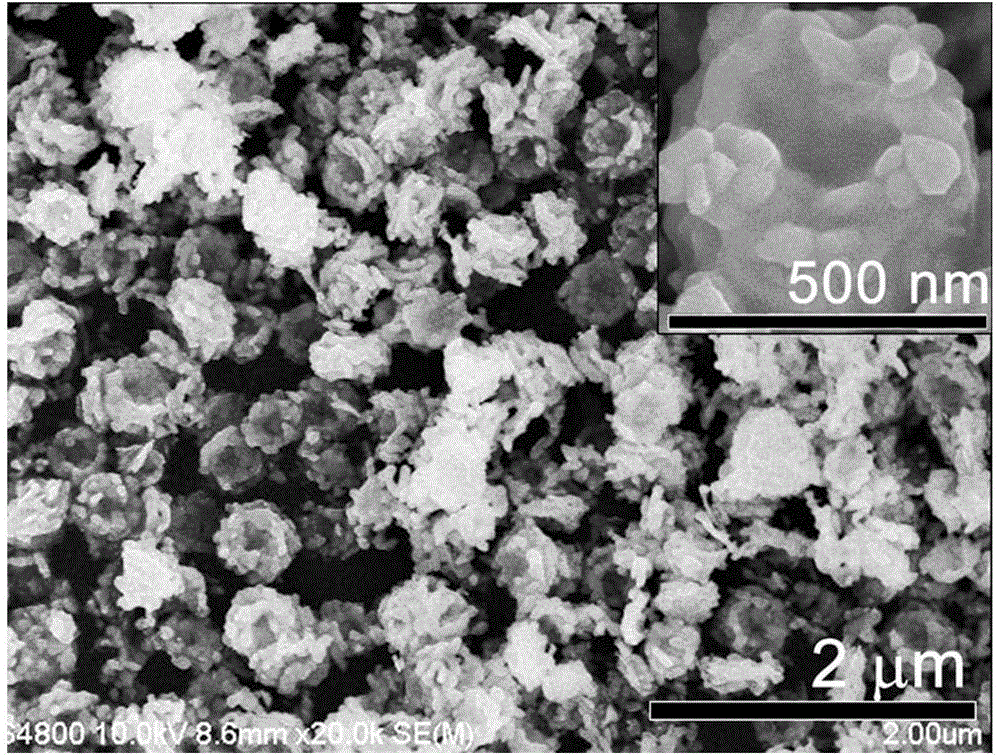

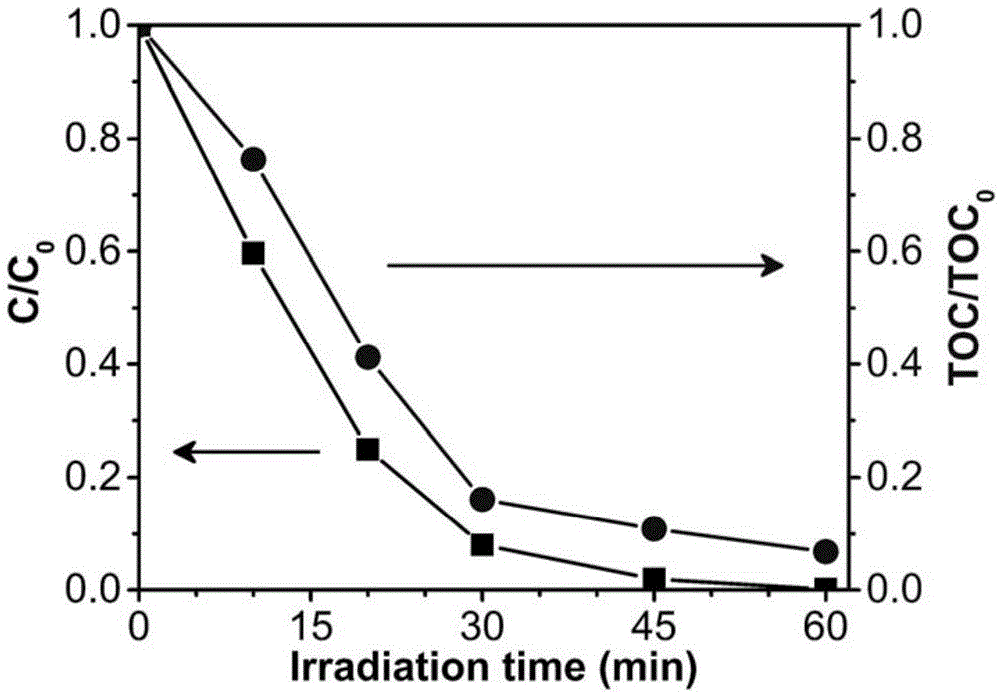

[0019] Add 1 g of bismuth nitrate pentahydrate and 1.5 g of L-asparagine monohydrate into 50 mL of distilled water, stir and dissolve thoroughly, then transfer the mixed solution to a 150 mL round bottom flask, and fully react for 4 hours in an oil bath at 100°C ; After the reaction is cooled down to room temperature, the reactant obtained from the reaction is centrifuged and washed, and the precipitate is washed 3 times with deionized water and ethanol respectively to obtain a white solid, which is placed in an oven and dried at 60°C for 12 hours; then The white solid was thoroughly ground, placed in a ceramic crucible, and calcined at 340° C. for 2 hours using a muffle furnace to obtain a light yellow solid powder, which is the nanoflower-shaped β-phase bismuth oxide photocatalyst. The X-ray diffraction pattern and scanning electron microscope morphology of the nanoflower-like β-phase bismuth oxide photocatalyst are shown in Fig. figure 1 and figure 2 shown. This nano-flo...

Embodiment 2

[0021] Add 1 g of bismuth nitrate pentahydrate and 2.0 g of L-asparagine monohydrate into 50 mL of distilled water, stir to dissolve, then transfer the mixed solution to a 150 mL round bottom flask, and fully react in an oil bath at 120°C for 6 hours ; After the reaction is cooled to room temperature, the reactant obtained from the reaction is centrifuged and washed, and the precipitate is washed 3 times with deionized water and ethanol respectively to obtain a white solid, which is placed in an oven and dried at 60°C for 12 hours; then The white solid was thoroughly ground, placed in a ceramic crucible, and calcined at 380° C. for 2 hours using a muffle furnace to obtain a light yellow solid powder, which is the nanoflower-shaped β-phase bismuth oxide photocatalyst. The nano-flower-like β-phase bismuth oxide photocatalyst was treated according to the method in Application Example 1 below, and the results showed that the target pollutant p-hydroxybiphenyl could be completely de...

Embodiment 3

[0023] Add 2 grams of bismuth nitrate pentahydrate and 4.5 grams of L-asparagine monohydrate into 100 mL of distilled water, stir and dissolve, then transfer the mixed solution to a 250 mL round bottom flask, and fully react in an oil bath at 140°C for 8 hours ; After the reaction is cooled to room temperature, the reactant obtained from the reaction is centrifuged and washed, and the precipitate is washed 3 times with deionized water and ethanol respectively to obtain a white solid, which is placed in an oven and dried at 60°C for 12 hours; then The white solid was thoroughly ground, placed in a ceramic crucible, and calcined at 400° C. for 2 hours in a muffle furnace to obtain a light yellow solid powder, which is the nanoflower-shaped β-phase bismuth oxide photocatalyst. The nano-flower-like β-phase bismuth oxide photocatalyst was treated according to the method in Application Example 1 below, and the results showed that the target pollutant p-hydroxybiphenyl could be comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com