Attapulgite-based composite material loaded Cu-Zn-Fe based catalyst, preparation method and applications thereof

A technology of cu-zn-fe and attapulgite, which is applied in the field of comprehensive utilization of resources, can solve problems such as the complexity of low-carbon alcohol reaction systems, achieve less strict requirements on preparation process parameters, save acid consumption, improve activity and low carbon The effect of alcohol selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

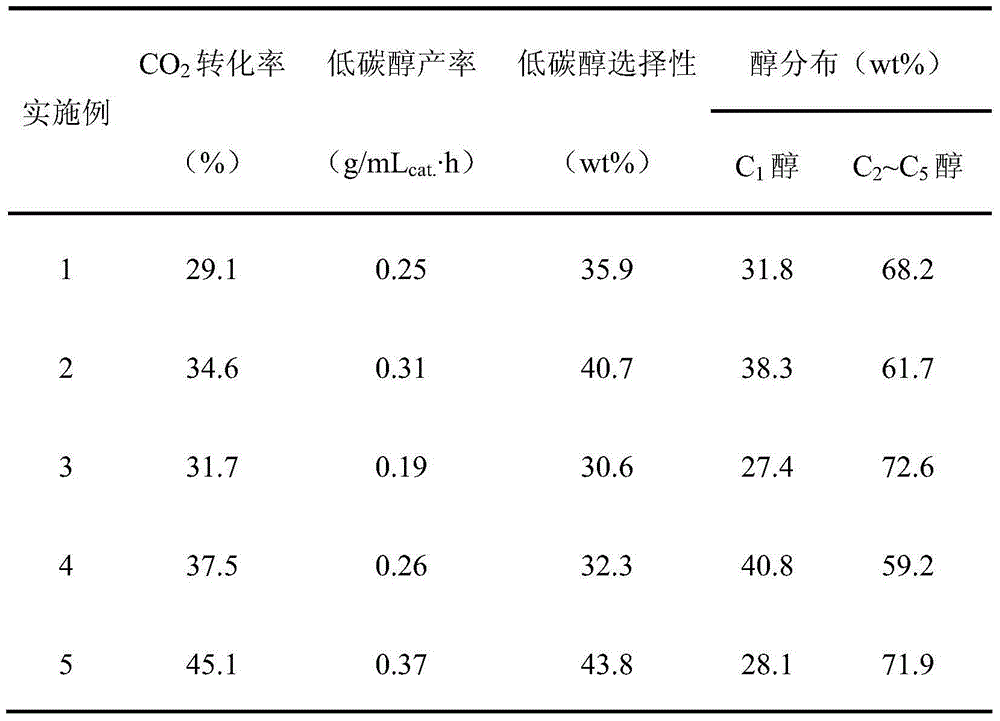

Examples

Embodiment 1

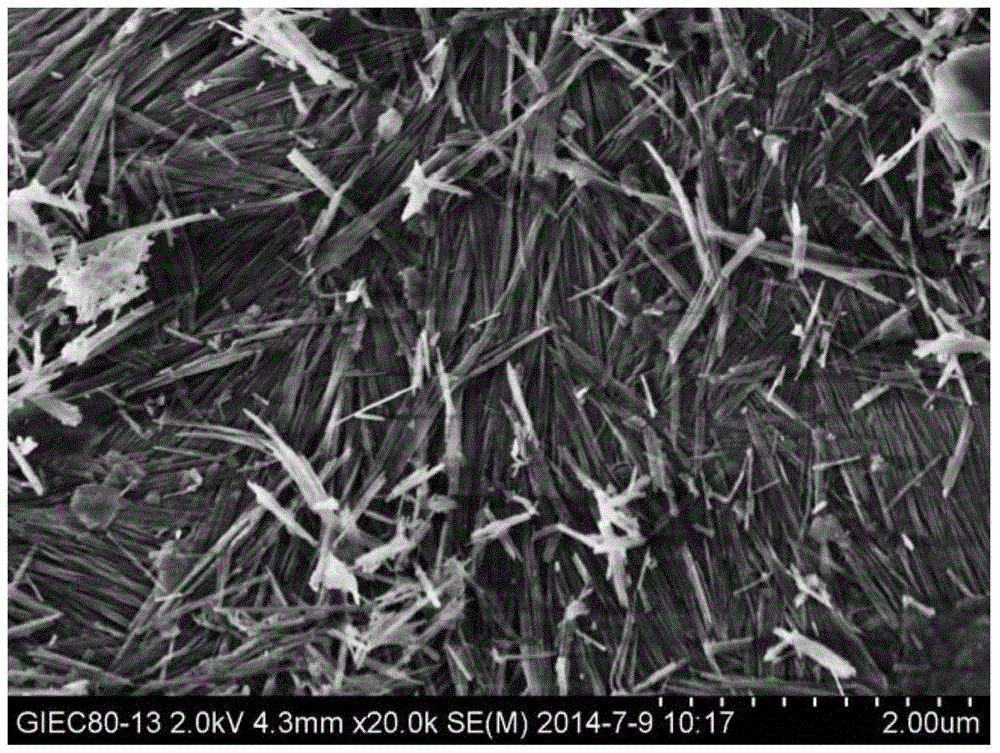

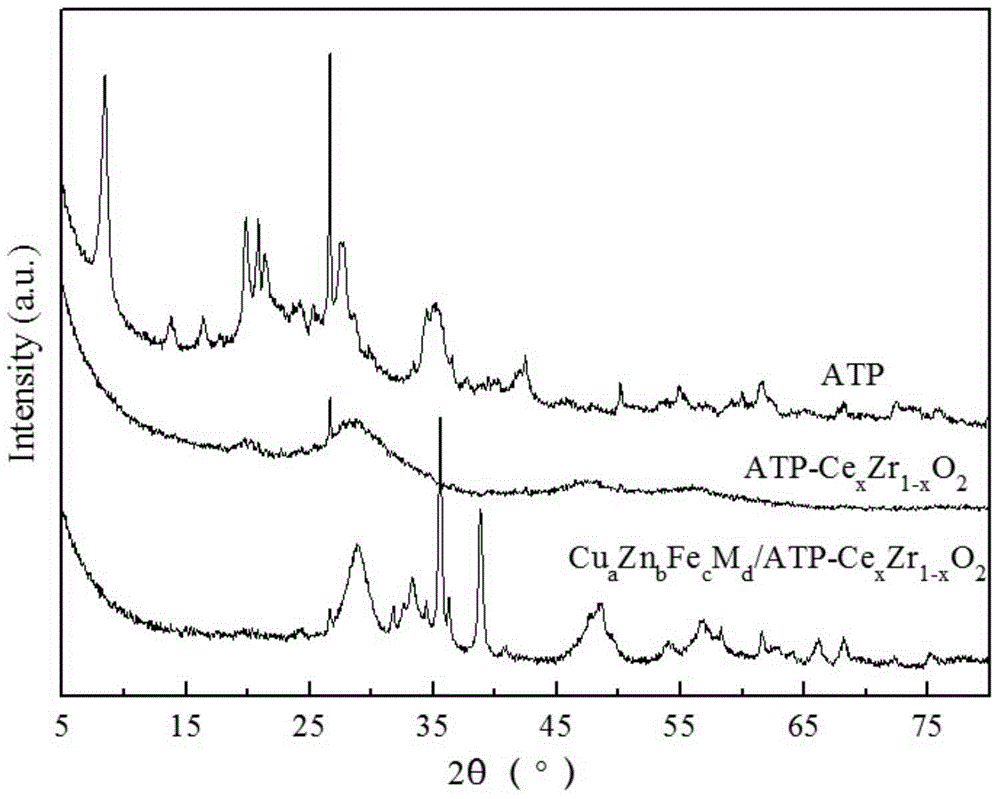

[0035] (1) Using 4wt% H 2 SO 4 Pressurized acid modification of attapulgite with solution: add 384g of water into a 500mL reactor and heat to 80°C, then add 80g of attapulgite ore and stir at constant temperature for 5min, and finally add 16g of 98wt% H 2 SO 4 , airtight reaction kettle (this embodiment forms certain vapor pressure by adding sulfuric acid solution by reacting in airtight reaction container, realizes the pressurized acid activation to attapulgite; What the embodiment of the present invention used is airtight 500mL reaction kettle , but other sealable reaction vessels can also be implemented; the pressure can also be controlled by feeding gas into the reaction vessel). Raise the temperature to 120°C, continue to stir and react at a constant temperature for 3 hours, discharge the material after the end, and filter the upper slurry after a period of static settling, wash the filter cake until neutral, dry it in an oven, and crush it through a 200-mesh standard s...

Embodiment 2

[0039] (1) Using 16wt% H 2 SO 4 Pressurized acid modification of attapulgite by solution: add 327.6g of water into a 500mL reactor and heat to 50°C, then add 130g of attapulgite ore and stir at constant temperature for 20min, and finally add 62.4g of 98wt% H 2 SO 4 , close the reaction kettle, heat up to 150°C, continue to stir and react at a constant temperature for 2 hours, discharge the material after the end, and filter the upper layer slurry after a period of static settling, wash the filter cake until neutral, dry it in an oven, and crush it to a standard of 200 mesh The acid-modified attapulgite powder was obtained by sieving, and placed in a desiccator for future use.

[0040] (2) Press Ce / Zr=1 / 19, Ce(NO 3 ) 3 ·6H 2O and ZrO(NO 3 ) 2 2H 2 O mixed and dissolved in water to obtain a cerium-zirconium precursor aqueous solution with a concentration of 0.5mol / L; weigh 20g of acid-modified attapulgite powder and disperse it in 100mL of water, and then press ATP / Ce x...

Embodiment 3

[0043] (1) Using 20wt% H 2 SO 4 Pressurized acid modification of attapulgite with solution: add 312g of water into a 500mL reactor and heat to 50°C, then add 65g of attapulgite ore and stir at constant temperature for 10min, and finally add 78g of 98wt% H 2 SO 4 , close the reaction kettle, heat up to 100°C, continue to stir and react at a constant temperature for 0.5h, discharge the material after the end, and filter the upper slurry after a period of static settling, wash the filter cake until neutral, dry it in an oven, and crush it through 200 mesh Acid-modified attapulgite powder was obtained by standard sieve and placed in a desiccator for later use.

[0044] (2) According to Ce / Zr=19 / 1, Ce (NH 4 ) 2 (NO 3 ) 6 with Zr(NO 3 ) 4 ·5H 2 O was mixed and dissolved in water to obtain an aqueous solution of cerium-zirconium precursor with a concentration of 3.0mol / L; 5g of acid-modified attapulgite powder was evenly dispersed in 100mL of water, and then ATP / Ce x Zr 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com