Based on modified bamboo powder pc/abs alloy and preparation method thereof

A technology of bamboo powder and alloy, applied in the field of PC/ABS alloy based on modified bamboo powder and its preparation, can solve the problem of no toughening effect and the like, and achieve the effects of reducing viscosity, improving impact performance of alloy, and overcoming agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

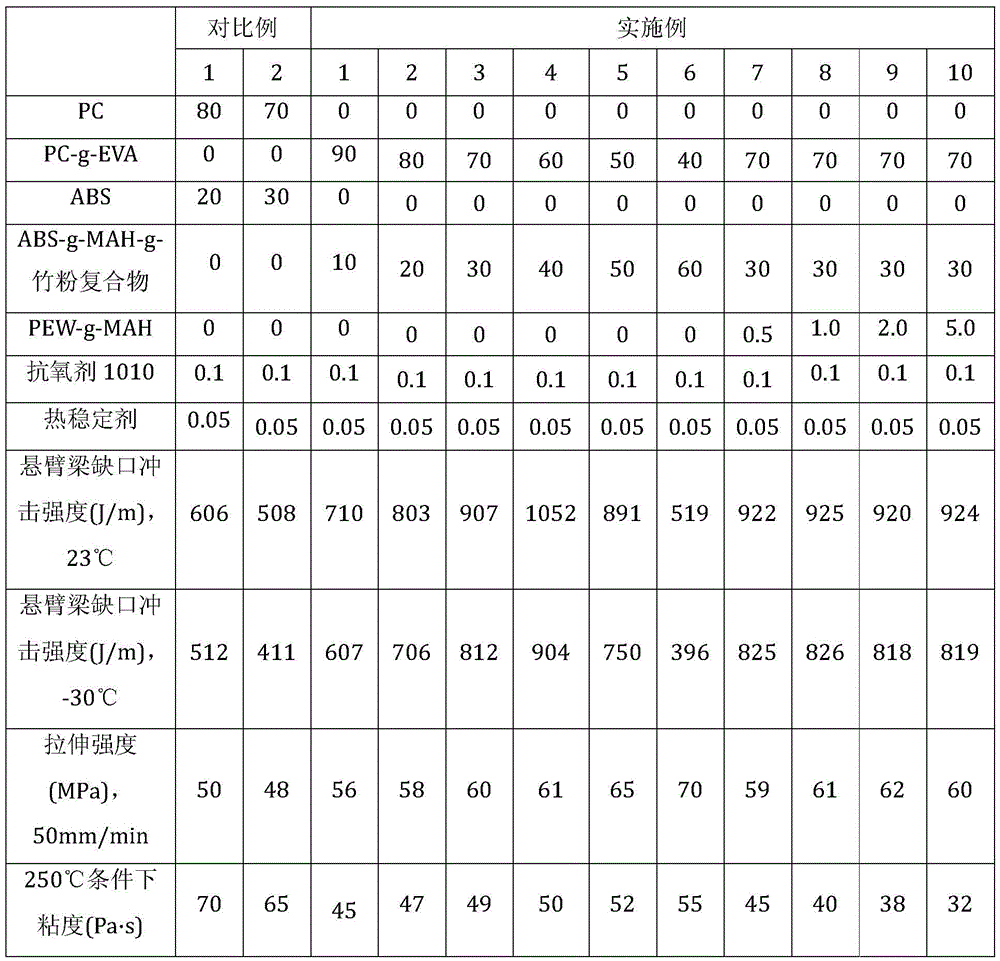

Examples

Embodiment

[0022] This embodiment includes the following steps:

[0023] 1) Preparation of PEW: Add LLDPE into a three-neck flask, heat and stir, nitrogen purging, melt at 180-200°C for 5-10min, then heat to 350-380°C for 5-6h, cool and discharge to obtain PEW.

[0024] 2) Preparation of PEW-g-MAH: Put PEW, MAH, and DCP in a four-necked flask according to the weight ratio (100-200): (30-80): (0.5-1.0), and then add the weight ratio (256-344 ) toluene, heated and stirred, heated to 100-120°C and stirred for 1-2h, cooled to 25°C, added acetone at a weight ratio (78-156) to obtain a white precipitate, and put it into a Soxhlet extractor after Buchner funnel suction filtration Acetone was refluxed for 8-10 hours, and dried at 50°C to obtain PEW-g-MAH graft copolymer with a graft ratio of 10-18%.

[0025] 3) ABS‐g‐MAH preparation: ABS, MAH, DCP and antioxidant by weight ratio (100‐400): (40‐100): (0.5‐1.0): (0.02‐0.1) in 100‐200r / After blending at a high speed for 5 min, the ABS‐g‐MAH graf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com