Preparation method of nanometer cobalt oxide/graphene composite material

A technology of tricobalt tetroxide and composite materials, which is applied in the field of materials, can solve the problems of reduced electrical conductivity of graphene, influence on catalytic performance, and inability to completely remove oxygen-containing functional groups, and achieve enhanced catalytic performance, short preparation cycle, and improved electron transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

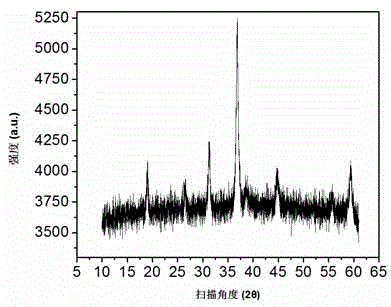

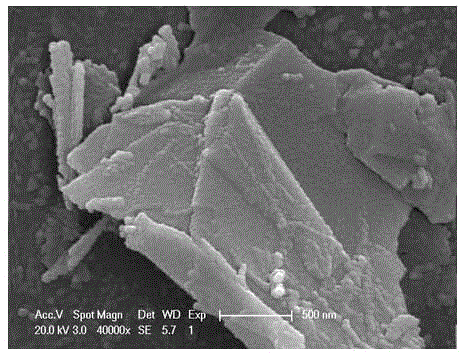

Image

Examples

Embodiment 1

[0028] A kind of preparation method of nano cobalt trioxide / graphene composite material, specifically comprises the following steps:

[0029] (1) Dissolve 12mmol of surfactant in 100ml of water, add 1g of graphite, after ultrasonication for 10h, centrifuge at 4000r / min for 10min, and take the supernatant;

[0030] Described tensio-active agent is CTAB;

[0031] The consumption of above-mentioned surfactant, water and graphite is by surfactant: water: graphite is the ratio calculation of 12mmol:100ml:1g;

[0032] Described graphite is natural flake graphite;

[0033] (2) Add 10 mmol of cobalt salt to the supernatant obtained in step (1) under stirring conditions, and continue stirring for 20-30 minutes to obtain solution A;

[0034] The cobalt salt is cobalt acetate, and its addition is calculated according to the ratio of cobalt salt: graphite used in the supernatant of the preparation step (1) being 10mmol: 1g;

[0035] (3) Dissolve 50mmol of urea in 20ml of water to form...

Embodiment 2

[0049] A kind of preparation method of nano cobalt trioxide / graphene composite material, specifically comprises the following steps:

[0050] (1) Dissolve 12mmol of surfactant in 100ml of water, add 1g of graphite, after ultrasonication for 30h, centrifuge at 000r / min for 30min, and take the supernatant;

[0051] Described tensio-active agent is CTAB;

[0052] The consumption of above-mentioned surfactant, water and graphite is by surfactant: water: graphite is the ratio calculation of 12mmol:100ml:1g;

[0053] Described graphite is natural graphite;

[0054] (2) Add 10 mmol of cobalt salt to the supernatant obtained in step (1) under stirring conditions, and continue stirring for 20 minutes to obtain solution A;

[0055] The cobalt salt is cobalt acetate, and its addition is calculated according to the ratio of cobalt salt: graphite used in the supernatant of the preparation step (1) being 10mmol: 1g;

[0056] (3) Dissolve 50mmol of urea in 20ml of water to form an aqueou...

Embodiment 3

[0061] A kind of preparation method of nano cobalt trioxide / graphene composite material, specifically comprises the following steps:

[0062] (1) Dissolve 12mmol of surfactant in 100ml of water, add 1g of graphite, ultrasonicate for 50h, centrifuge at 4000r / min for 10min, and take the supernatant;

[0063] Described tensio-active agent is CTAB;

[0064] The consumption of above-mentioned surfactant, water and graphite is by surfactant: water: graphite is the ratio calculation of 12mmol:100ml:1g;

[0065] Described graphite is graphite microsphere;

[0066] (2) Add 10 mmol of cobalt salt to the supernatant obtained in step (1) under stirring conditions, and continue stirring for 30 minutes to obtain solution A;

[0067] The cobalt salt is cobalt acetate, and its addition is calculated according to the ratio of cobalt salt: graphite used in the supernatant of the preparation step (1) being 10mmol: 1g;

[0068] (3) Dissolve 50mmol of urea in 20ml of water to form an aqueous u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com