System for producing anhydrous calcium chloride by using industrial waste hydrochloric acid, and technology thereof

A technology of anhydrous calcium chloride and calcium chloride, which is applied in the direction of calcium/strontium/barium chloride, the use of liquid separation agents, chemical instruments and methods, etc., which can solve the problem of difficult large-scale continuous production and the area occupied by reaction vessels Large scale, improper treatment of reaction tail gas and other problems, to achieve great social and environmental benefits, realize continuous production, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

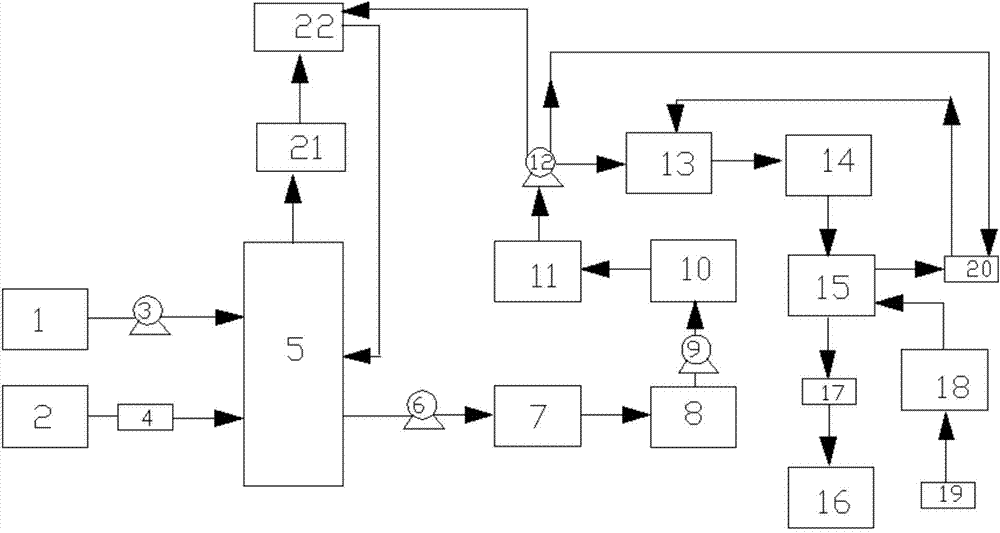

[0030] Such as figure 1 As shown, a system for producing anhydrous calcium chloride by utilizing industrial waste hydrochloric acid includes a reaction system, a three-effect multistage evaporator 13, a drying system, a reaction tail gas treatment system and a dry tail gas scrubber 20.

[0031] Wherein, the reaction system includes a hydrochloric acid storage tank 1, a limestone powder storage tank 2, a hydrochloric acid pump 3, a belt conveyor 4, a calcium chloride reactor 5, a reaction liquid extraction pump 6, a neutralization tank 7, and a crude calcium chloride sedimentation Groove 8, filter press pump 9, thick calcium chloride filter press 10 and refined calcium chloride storage tank 11; Described drying system comprises drying fluidized bed 15, electric heater 18 and blower 19; Described reaction tail gas treatment system It includes a reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com