Reciprocating type circular curing device and technology

A reciprocating and technological technology, which is applied in the field of reciprocating cyclic maintenance devices and maintenance technology, can solve problems such as low environmental protection level, environmental pollution, and unfavorable long-term development of enterprises, so as to improve maintenance efficiency, facilitate popularization and application, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

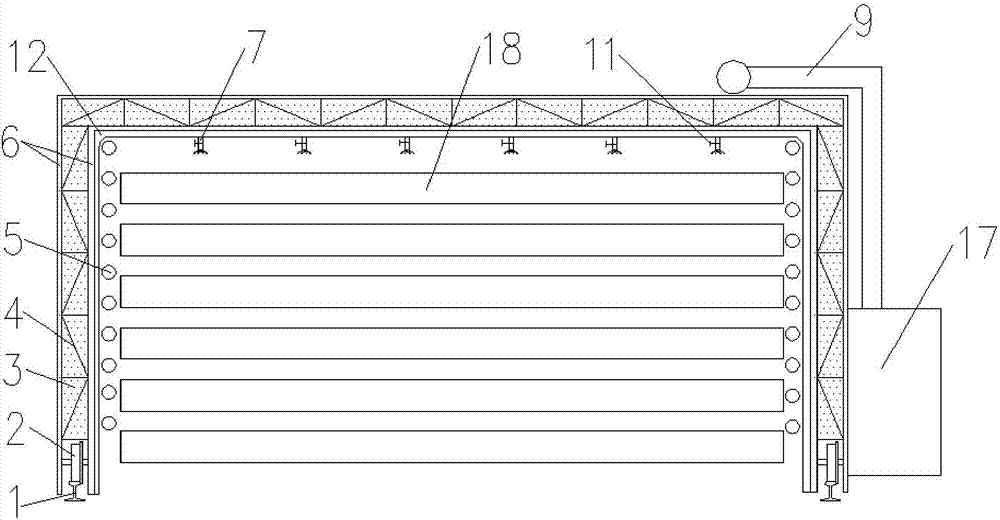

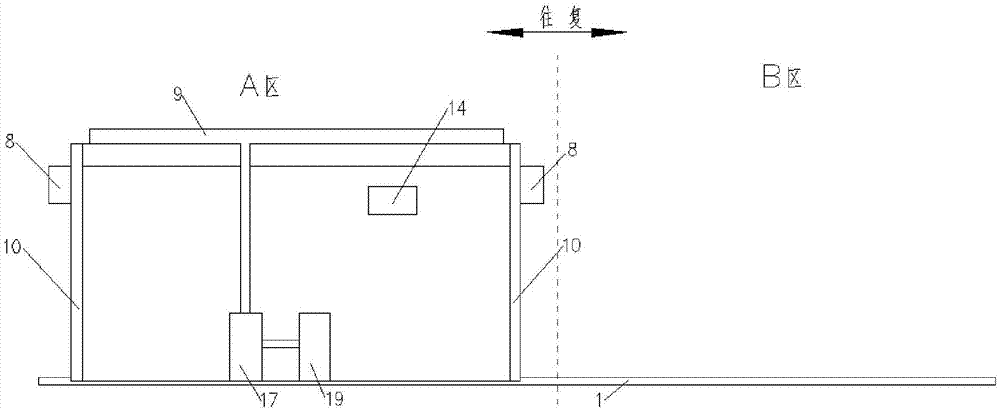

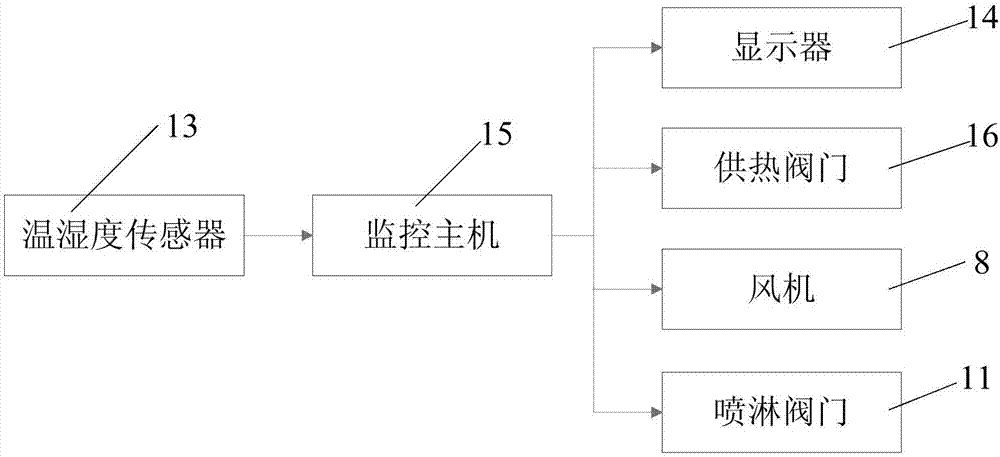

[0036] Such as figure 1 , figure 2 and image 3A reciprocating circulation maintenance device shown includes a track 1 and a curing room moving along the track 1, the length of the track is twice the length of the curing room, and the bottom of the curing room is provided with a The track wheel 2 is used to cooperate with the track 1 to realize reciprocating movement. The two sides of the curing room perpendicular to the moving direction are provided with airtight doors 10, and the inner wall of the curing room is coated with a waterproof layer 12. The curing A heating system for providing heat to the curing room, a spray system for increasing the humidity in the curing room, a temperature and humidity monitoring system for monitoring the temperature and humidity in the curing room and a temperature and humidity control system for adjusting the temperature and humidity in the curing room are installed on the room. Regulating system; a monitoring host is installed outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com