Comprehensive utilization method and device for acid dissolution extraction of valuable element chromium silicon iron magnesium aluminum nickel from chromite

A stirring device and material chamber technology, which is applied in the field of comprehensive mining and utilization of chromite, can solve the problems of not being able to remove ions cleanly and fail to achieve high-purity purposes, and achieve good economic benefits, high raw material utilization, and low discharge of three wastes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] An ionic membrane impurity removal device, such as Figure 7 As shown, it is characterized in that: it includes an anode chamber 1, a cathode chamber 2, and a material chamber 3, and the material chamber 3 is located between the anode chamber 1 and the cathode chamber 2,

[0084] in,

[0085] The anode chamber is provided with an anode 11, which is separated from the material chamber by an anion membrane 4;

[0086] The cathode chamber is provided with a cathode 21, which is separated from the material chamber by a cationic membrane 5;

[0087] The material chamber is provided with a material basket 31 containing solid insoluble matter, and a stirring device 32 is provided at the bottom.

[0088] The anode chamber 1 is also provided with a first pure water injection port 12, a first waste liquid discharge port 13, a first waste gas collection device 14; the cathode chamber 2 is also provided with a second pure water injection port 22, a second waste Liquid disc...

Embodiment 2

[0093] A process for removing impurities from ionic impurities in chemical precipitation, which is beneficial to the above-mentioned devices (such as Figure 7 shown), including the following steps:

[0094] 1) Before electrolysis: put the solid product produced in the chemical synthesis in the material blue 31 in the material chamber, and inject a sufficient amount of pure water into the anode chamber 1, the cathode chamber 2 and the material chamber 3, at this time, the material blue It is also soaked in water, and the soluble ions attached to the surface of the solid product are fully dissolved in pure water under stirring;

[0095] 2) Electrolysis: Under the action of the electrode, the anion is electrolyzed into gas at the anode through the anion membrane, and the gas is recovered, and the cation is electrolyzed into metal and alkali metal or precipitated at the cathode through the anion membrane, and the electrolysis is terminated when hydrogen gas is generated at the c...

Embodiment 3

[0098] A comprehensive utilization method for extracting valuable elements chromium, silicon, iron, magnesium, aluminum and nickel by acid dissolution of chromite, the specific process steps are as follows:

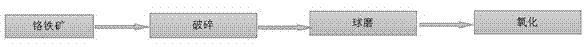

[0099] 1) Chromite ore processing (see attached figure 1 )

[0100] After the chromite ore is mined, it is crushed and ball milled into a powder with a particle size of less than 100 microns, placed in an electrode oxidation tank, and water is added to the ore powder to keep the water content of the ore powder at 10wt%-15wt%, so that the ore powder is moist and the electrode is oxidized Air is blown into the bottom of the tank;

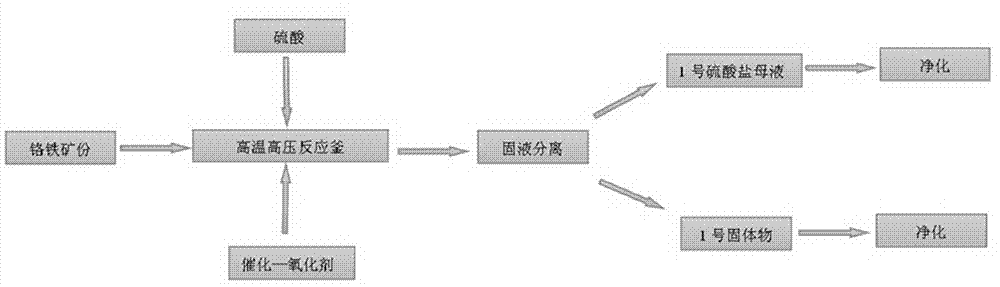

[0101] 2) acid soluble (see attached figure 2 )

[0102] Mineral powder is placed in a high-temperature and high-pressure reactor to react with 50wt%-70wt% sulfuric acid solution, wherein the amount of sulfuric acid added is: the mass ratio of mineral powder to sulfuric acid is 1:2 to 1:3, and the temperature of the reactor is 120 ° C ~ 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com