Method for reactive spraying preparation of ceramic solid solution-based ceramic-metal eutectic nanometer composite coating

A nanocomposite coating and solid solution technology, which is applied in the direction of metal material coating process, coating, fusion spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

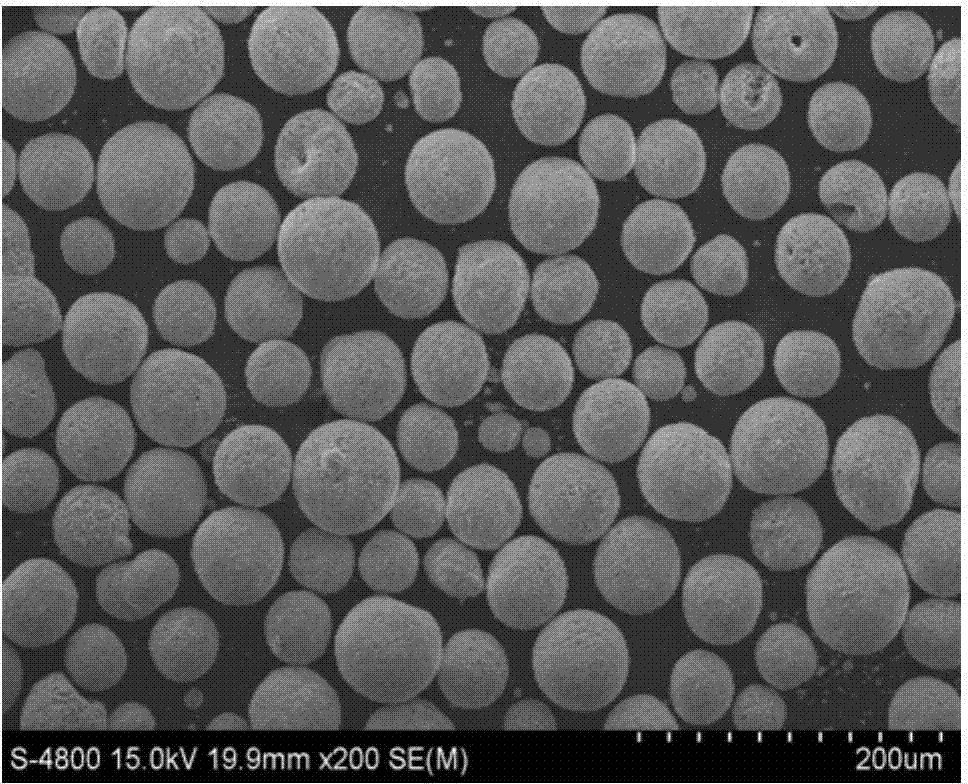

Image

Examples

Embodiment 1

[0061] The first step, raw materials and configuration of composite powder

[0062] Selection of raw material powder: commercial Al powder for spraying, particle size 6μm; commercial (industrial or reagent) Cr 2 o 3 powder, submicron particle size; commercial ultrafine Al 2 o 3 Spray powder, average particle size 6μm; ultra-fine commercial CeO 2 Powder, particle size 100-150nm.

[0063] Configuration of raw materials: first Cr 2 o 3 Al powder and Al powder were configured into the original reaction system at a mass ratio of 3:1; based on the original reaction system, 1.5 times the mass ratio of (Cr 2 o 3 +Al 2 o 3 +CeO 2 ) additives, Al in additives 2 o 3 : Cr 2 o 3 =2:3 (mass ratio), CeO 2 The addition amount of is 1.0wt% of additive.

[0064] The second step, the preparation of composite powder

[0065] Wet depolymerization - prepare deionized water according to the ratio of solid content 50Wt%; prepare various solid powders Cr 2 o 3 (Referring to all Cr i...

Embodiment 2

[0076] The first step, the preparation of composite powder

[0077] Selection of raw material powder: commercial Al powder for spraying, particle size 9μm; commercial (industrial or reagent) Cr 2 o 3 powder, submicron particle size; commercial ultrafine Al 2 o 3 Spray powder, average particle size 10μm; ultrafine commercial NdO 2 Powder, particle size 100-150nm.

[0078] Configuration of raw materials: first Cr 2 o 3 powder and Al powder according to the mass ratio of 3:1 to prepare the original reaction system powder; based on the original reaction system powder, add 1.8 times (Cr 2 o 3 +Al 2 o 3 +NdO 2 ) additives, NdO in additives 2 The addition amount of 1.5wt%, Al 2 o 3 : Cr 2 o 3 =1:1.

[0079] The second step, the preparation of composite powder

[0080] Wet depolymerization—prepare deionized water according to the ratio of 50% of the total solid-liquid; the prepared Cr 2 o 3 、Al 2 o 3 , NdO 2 The powder was added with deionized water and a dispers...

Embodiment 3

[0090] The first step, the preparation of composite powder

[0091] Selection of raw material powder: commercial Al powder for spraying, particle size 9μm; commercial (industrial or reagent) Cr 2 o 3 powder, submicron particle size; commercial ultrafine Al 2 o 3 Spray powder, average particle size 12μm, commercial ultrafine CeO 2 Powder, the particle size is 150-200 nanometers.

[0092] Configuration of raw materials: first Cr 2 o 3 Powder and Al powder are prepared according to the mass ratio of 3:1; add 2.1 times (Cr 2 o 3 +Al 2 o 3 +CeO 2 ) additives, Al in additives 2 o 3 : Cr 2 o 3 =1:2 (mass ratio), CeO 2 The addition amount of is 2.0wt%.

[0093] The second step, the preparation of composite powder

[0094] Wet depolymerization - prepare deionized water according to the ratio of 40wt% of the total solid-liquid; 2 o 3 、Al 2 o 3 , CeO 2 The powder is divided into different containers, and deionized water and a dispersant with a solid content of 0.8wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com