Hydrophobic association water-soluble xanthan gum and preparation method and application thereof

A xanthan gum, modified technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reaction yield and molecular weight to be improved, poor thermal stability of xanthan gum solution, easy to be decomposed by bacteria, etc. , to achieve the effects of improving biological stability, better anti-aging performance, and stable properties of reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

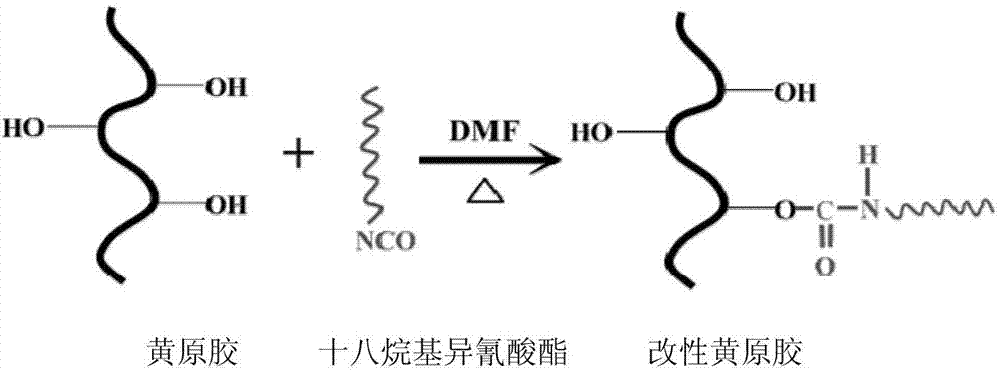

Method used

Image

Examples

Embodiment 1

[0040] Take 5.58g of XG after vacuum drying (vacuum drying temperature is 25°C, vacuum degree is 0.096MPa, time is 24h), add 120ml DMF, fully stir and swell at 40°C for 12h.

[0041] Take 0.4g of octadecyl isocyanate and dissolve it in 30ml of DMF, add it dropwise to the system with a constant pressure dropping funnel, raise the temperature to 80°C, and react for 6h.

[0042]After the reaction was completed, cool to room temperature, add the reaction solution together with the solid product to 350ml acetone, wash thoroughly and let stand and discard the supernatant, collect the precipitate and wash with ethanol 4 times, 400ml each time. After suction filtration, the product was vacuum-dried at 25° C. for 24 hours and pulverized to obtain 5.60 g of the modified xanthan gum provided by the present invention. Through static light scattering test, its apparent weight average molecular weight is 3.04 million.

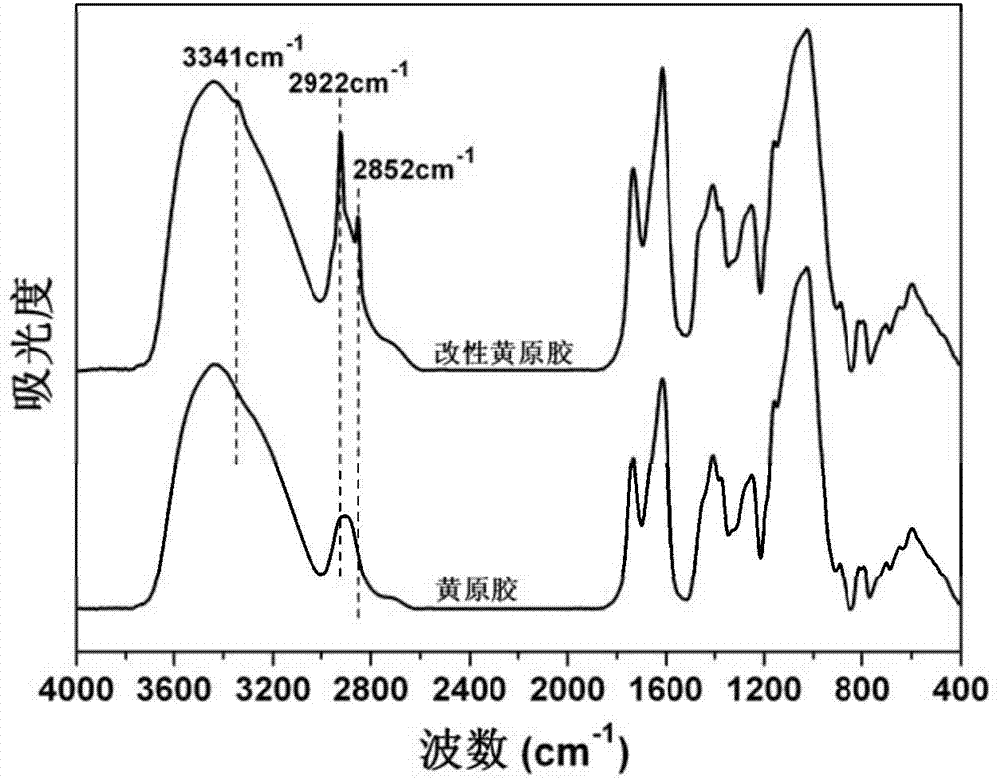

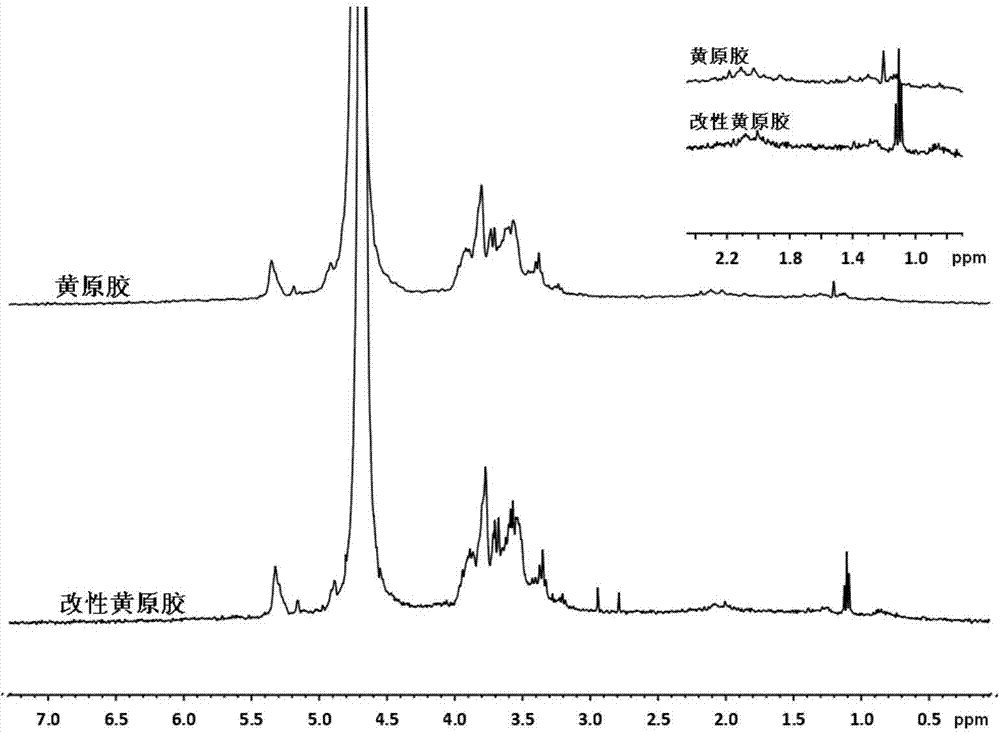

[0043] figure 2 It is the infrared spectrum of xanthan gum and the m...

Embodiment 2

[0065] As described in Example 1, the difference is that the amount of octadecyl isocyanate in step (3) is changed to 0.8g to obtain 5.82g modified xanthan gum.

[0066] The apparent weight-average molecular weight of the modified xanthan gum measured by static light scattering is 3.98 million. The salt resistance, temperature resistance, anti-aging performance and surface tension data of the modified xanthan gum in this example are shown in Table 6, Table 7, Table 8 and Table 9 respectively.

[0067] Table 6. Viscosity of xanthan gum in NaCl solution before and after modification

[0068] NaCl concentration (mol / L)

0

0.25

0.5

0.75

1

Xanthan Gum Viscosity (mPas)

181

153

156

159

164

Viscosity of modified xanthan gum (mPas)

221

175

186

188

191

[0069] Table 7, the viscosity of xanthan gum at different temperatures before and after modification

[0070] temperature(℃)

35

...

Embodiment 3

[0076] As described in Example 1, the difference is that the amount of octadecyl isocyanate in step (3) is changed to 1.2g to obtain 6.03g modified xanthan gum. The apparent weight-average molecular weight of the modified xanthan gum measured by static light scattering is 4.93 million.

[0077] The salt resistance, temperature resistance, aging resistance and surface tension data of the modified xanthan gum in this example are shown in Table 10, Table 11, Table 12 and Table 13 respectively.

[0078] Table 10. Viscosity of xanthan gum in NaCl solution before and after modification

[0079] NaCl concentration (mol / L)

0

0.25

0.5

0.75

1

Xanthan Gum Viscosity (mPas)

181

153

156

159

164

Viscosity of modified xanthan gum (mPas)

204

169

172

175

179

[0080] Table 11. The viscosity of xanthan gum at different temperatures before and after modification

[0081] temperature(℃)

35

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com