An industrial sewage treatment system

A technology for industrial sewage and treatment systems, applied in the direction of heating water/sewage treatment, heat recovery systems, energy-saving heating/cooling, etc., can solve the problems of sewage with high COD content, such as ineffective effects, non-continuous production, and energy waste. Achieve the effect of maximizing energy utilization, harmless sewage treatment, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

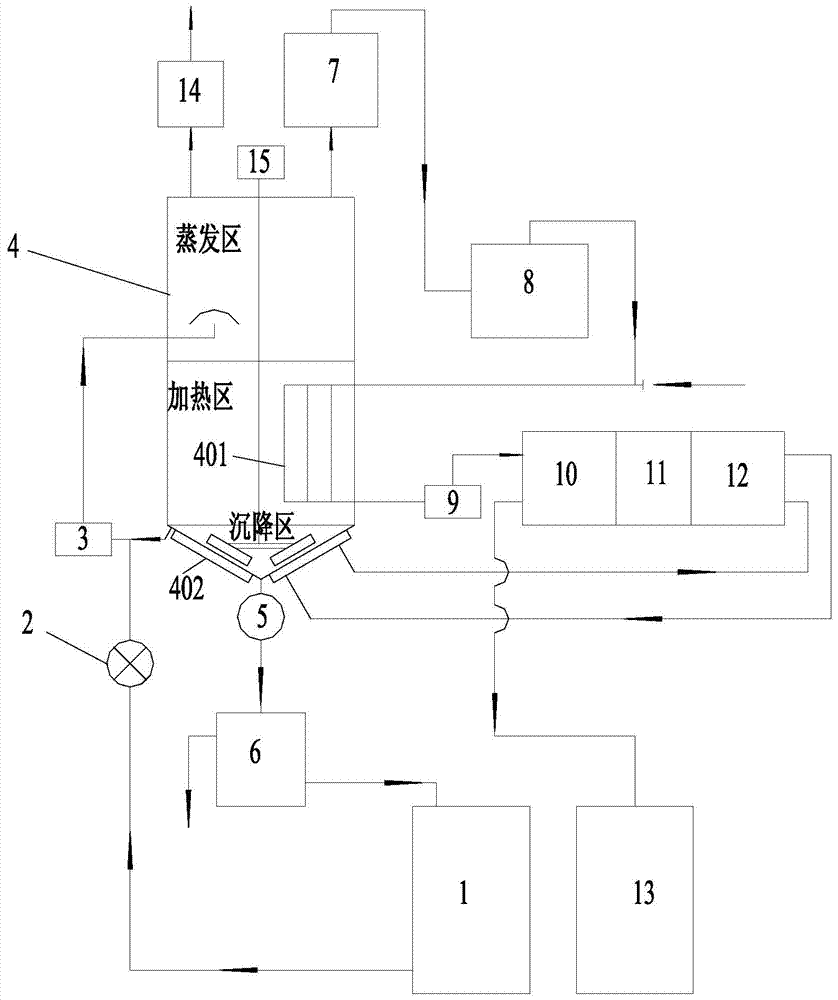

[0022] Such as figure 1 As shown, an industrial sewage treatment system includes a sewage storage tank 1, a sewage pipeline, a control valve 2, a chemical pump 3, an MVR evaporation system and a reclaimed water storage tank 13, and industrial sewage flows through the sewage pipeline from the sewage storage tank 1 After the flow is controlled by the control valve 2, the industrial sewage is pumped to the MVR evaporation system by the chemical pump 3;

[0023] The MVR evaporation system includes an evaporator 4 and a compressor 8. The evaporator 4 is composed of an evaporation zone, a heating zone and a settling zone. The evaporation zone receives the industrial sewage transported by the chemical pump 3, and the sewage is negatively charged in the evaporation zone. Pressure evaporation to obtain steam and concentrated liquid, the steam enters the compressor 8 after steam-water separation by the steam-water separator 7, and circulates into the shell-and-tube heat exchanger 401 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com