A shell-distributed Fischer-Tropsch synthesis catalyst and preparation method thereof

A technology of Fischer-Tropsch synthesis and catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures. effect, guarantee the effect of impregnation, and improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

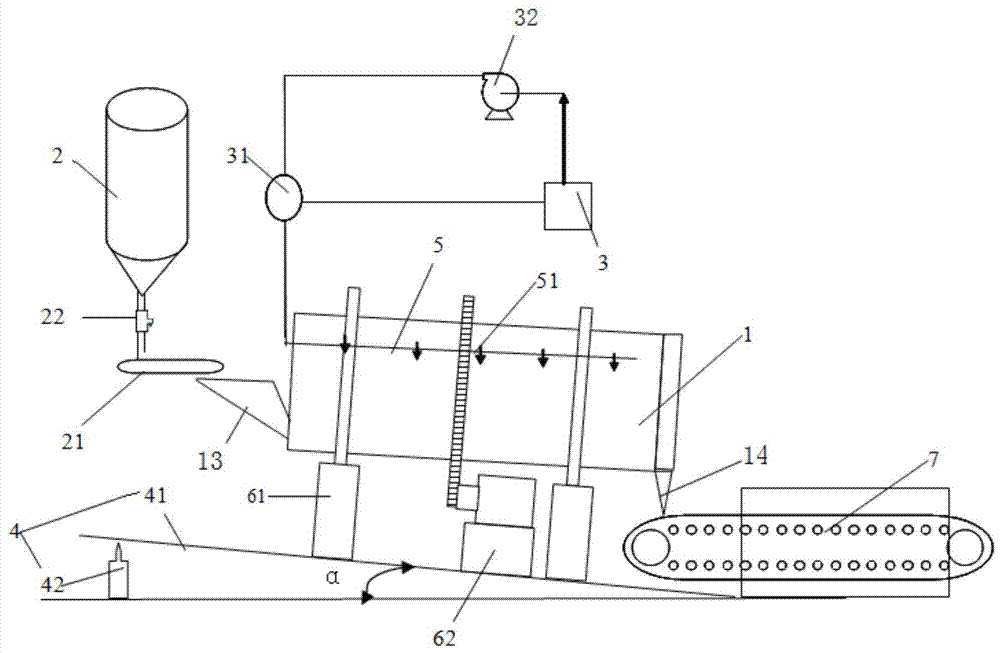

[0047] In order to be more conducive to the preparation of the catalyst in the present invention, preferably, the rotating speed of the rotating drum 1 and / or the inclination angle of the rotating drum 1, and / or the spray flow rate of the active component solution can be designed to be adjustable, specifically, for example In this way, when the amount of the catalyst carrier is constant, the turning speed of the catalyst carrier can be changed by adjusting the rotating speed of the drum 1, thereby adjusting the impregnation uniformity of the catalyst carrier, and by adjusting the inclination angle α of the drum 1, the catalyst carrier can be changed. The moving speed of the carrier in the drum 1 and the impregnation effect of the catalyst carrier can also be changed by adjusting the spray flow rate of the active component solution. Therefore, by adjusting and setting various parameters that match, a smaller amount of active component solution can be used to achieve a good catal...

Embodiment approach

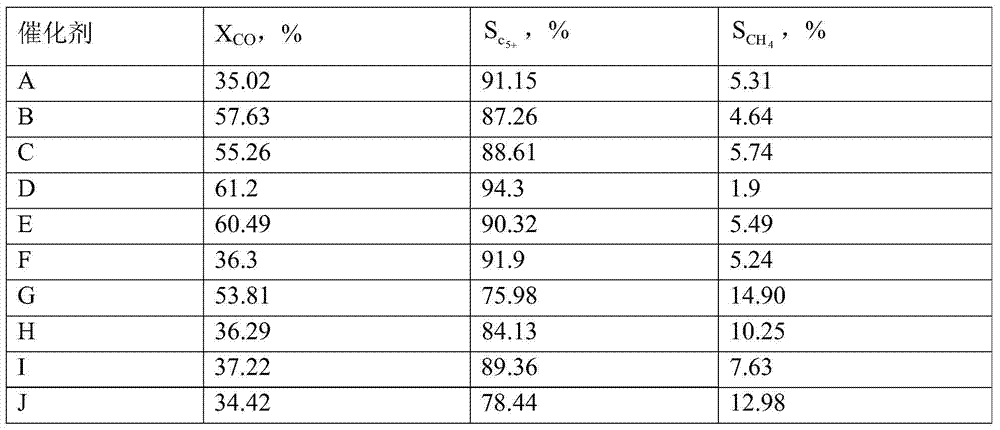

[0061] Therefore, according to a preferred embodiment of the present invention, the active component solution contains a water-soluble compound of iron and / or a water-soluble compound of cobalt and / or a water-soluble compound of ruthenium and water, and the active component solution The total concentration of the water-soluble compound of iron and / or the water-soluble compound of cobalt and / or the number of times of contact of the water-soluble compound of ruthenium and the number of contacts make in the obtained catalyst, based on the total amount of catalyst and in terms of oxides, iron and / or cobalt And / or the total content of ruthenium is 0.5 to 60% by weight, preferably 2 to 40% by weight.

[0062] Preferably, the total concentration of the water-soluble compound of iron and / or the water-soluble compound of cobalt and / or the number of contacts of the water-soluble compound of ruthenium in the active component solution makes the obtained catalyst contain In terms of oxides...

Embodiment 1

[0083] 1. Put butterfly-shaped γ-alumina particles with a 1.6mm orifice plate (the particle length is 2 to 4 mm, and its water absorption rate is measured to be 0.8 ml / g) as the catalyst carrier and put it into the hopper-type carrier storage device 2, through the second adjustment The transport of the device 22 and the second conveyor belt 21 enters the feed hopper 13 of the drum 1 .

[0084] 2. The active component solution (cobalt nitrate aqueous solution, wherein the concentration of cobalt nitrate is 1 g / ml) in the tank type solution storage device 3 is transported through the pumping mechanism 32 first, then passes through the first regulating device 31, and enters the spray bar 5 And atomizing nozzle 51. The atomizing nozzle is a pressure nozzle capable of atomizing the solution and spraying it into the drum 1 .

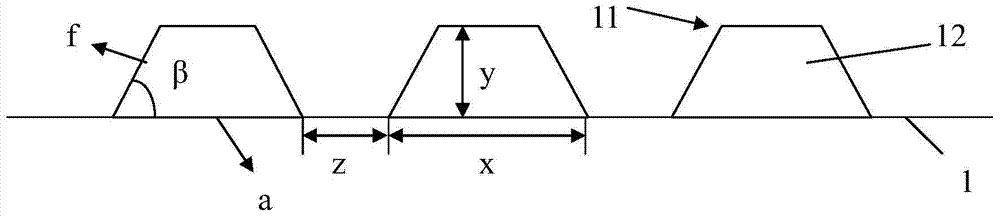

[0085] 3. The drum 1 is driven by the rotating drive device 62 at a speed of 5 rpm. The inner wall of the drum 1 is provided with a turning member 11 (the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com