Continuous preparation method of biodiesel

A biodiesel, animal and vegetable oil technology, applied in the fields of biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of unseen invention and application, reduce labor intensity, avoid serious equipment corrosion, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

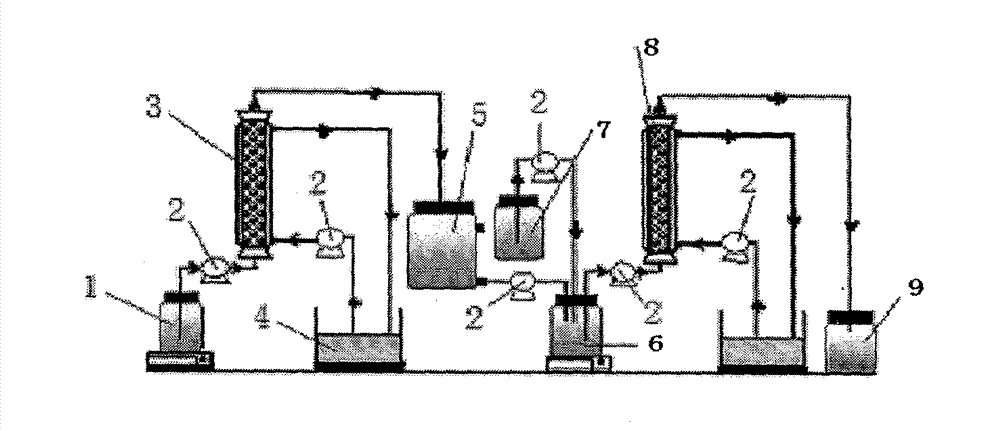

[0032] The flow chart of the process used is attached figure 1 shown. First remove solid impurities and colloids in the raw food waste oil by plate and frame filtration at 50°C, then remove moisture from the raw material by vacuum distillation for 30 minutes, and store it in the raw material tank 1. Get 900 grams of catering garbage oil with a free fatty acid content of 10% through removal of impurities, add 100 grams of methanol therein, stir evenly, and preheat to 65 ° C; the reactant is added to the cation exchange resin (001 × 7) by a feed pump In the first fixed-bed reactor 3, the reactant temperature is kept at 65°C with a circulating water bath, and the space velocity of the reactor is adjusted to be 0.25h -1 , allowing the free fatty acid in the food waste oil to undergo esterification reaction with methanol to obtain fatty acid methyl ester and water. The product flowing out is collected in the separation tank 5 and left to stand for stratification. The upper layer...

Embodiment 2

[0036] The flow chart of the process used is attached figure 1 shown. Get 1200 grams of waste frying oil with a free fatty acid content of 50% through removal of impurities, add 600 grams of ethanol therein, stir evenly, and preheat to 78 ° C; the reactant is added to the cation exchange resin (NKC-9 ) in the first fixed-bed reactor 3, keep the reactant temperature at 78°C with a circulating water bath, and adjust the reactor space velocity to 0.1min -1 , let the free fatty acid in waste frying oil undergo esterification reaction with ethanol to obtain fatty acid ethyl ester and water. The product flowing out is collected in the separation tank 6 and left to stand for stratification. The upper layer of the separation tank 6 is a mixture of ethanol, unreacted free fatty acid and generated water, and ethanol and free fatty acid can be recovered after separation. The lower layer is a mixture of fatty acid glycerides and fatty acid ethyl esters, which is stored in the intermedi...

Embodiment 3

[0039] The flow chart of the process used is attached figure 1 shown. Get 1000 grams of acidified oil with a free fatty acid content of 90% after removal of impurities, add 500 grams of propanol therein, stir evenly, and preheat to 97 ° C; the reactant is added to the first stage of the cation exchange resin (D61) by a feed pump In a fixed bed reactor 3, a circulating water bath is used to keep the temperature of the reactants at 97°C, and the space velocity of the reactor is adjusted to be 0.08min -1 , let the free fatty acid in the acidified oil undergo esterification reaction with propanol to obtain fatty acid propyl ester and water. The product flowing out is collected in the separation tank 6 and left to stand for stratification. The upper layer in the separation tank 6 is a mixture of propanol, unreacted free fatty acid and generated water, and propanol and free fatty acid can be recovered after separation. The lower layer is a mixture of fatty acid glyceride and fatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com