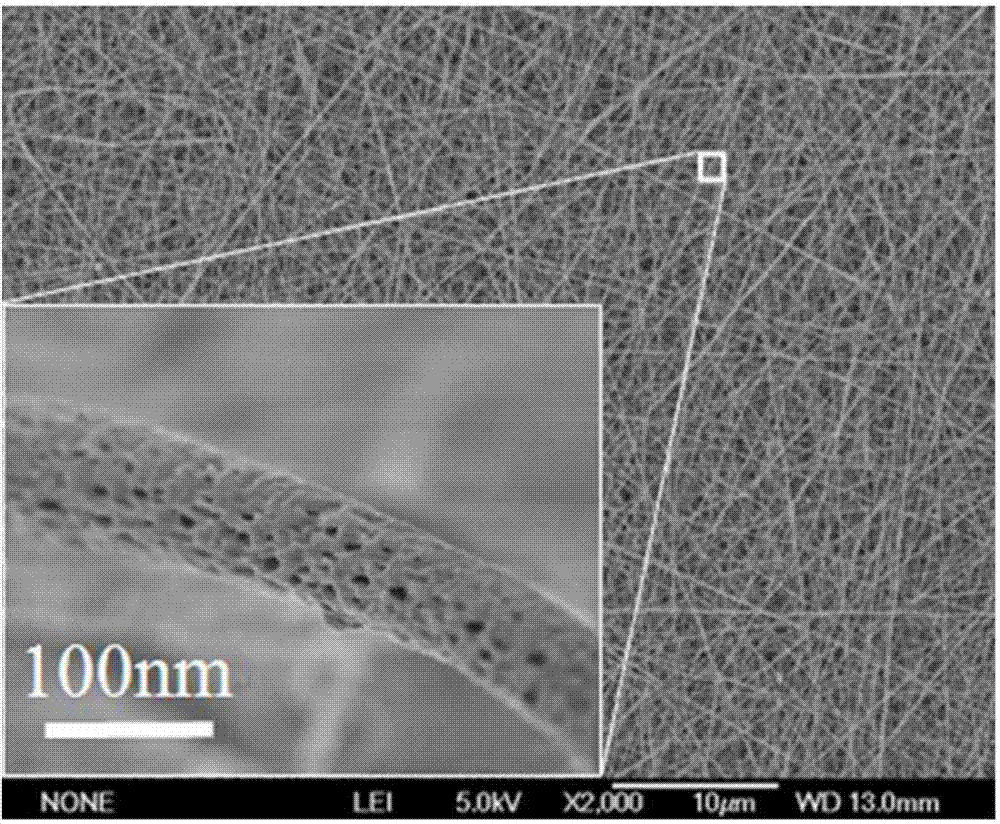

Preparation method of fluorine-containing polymer porous nano-micron fibre electrode diaphragm

A technology of fiber electrodes and polymers, which is applied in the direction of circuits, electrical components, battery pack components, etc., can solve the problems of low liquid holding capacity, easy fusion, and poor mechanical strength of non-porous fiber separators, and achieve good thermal stability. Stability and acid and alkali resistance, improved cycle life, and improved power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1. Preparation of spinning precursor

[0033] Dissolve 2.0g of polyvinylidene fluoride (number-average molecular weight: 200,000) and 2.0g of zinc acetate (mass ratio: 1:1) in N,N-dimethylformamide to prepare the mass ratio concentration of polyvinylidene fluoride 20% of the spinning precursor;

[0034] 1.2. Preparation of polyvinylidene fluoride-zinc acetate electrospun fiber membrane

[0035] The prepared spinning precursor is electrospun with the copper mesh as the receiver, the voltage of the electrospinning is 10kV, the distance between the needle and the receiver (spinning spacing) is 10cm, and polyvinylidene fluoride-acetic acid is obtained on the receiver. Zinc electrospun fiber membrane, after 30 minutes of electrospinning, the polyvinylidene fluoride-zinc acetate electrospun fiber membrane was vacuum-dried at 40°C for 24 hours for later use;

[0036] 1.3. Preparation of polyvinylidene fluoride-zinc oxide electrospun fibers

[0037] Add the polyvinylidene ...

Embodiment 2

[0042] 1.1. Preparation of spinning precursor

[0043] Dissolve 2.0 g poly(vinylidene fluoride-co-hexafluoropropylene) (number average molecular weight: 50,000) and 0.4 g copper acetate (mass ratio: 5:1) in N,N-dimethylacetamide / acetone ( In the mixed solution with a mass ratio of 3:7), it is prepared into a spinning precursor whose mass ratio concentration of poly(vinylidene fluoride-co-hexafluoropropylene) is 12%;

[0044] 1.2. Preparation of poly(vinylidene fluoride-co-hexafluoropropylene)-copper acetate electrospun fiber membrane

[0045]The prepared spinning precursor is electrospun with the copper mesh as the receiver, the voltage of the electrospinning is 15kV, the distance between the needle and the receiver is 15cm, and poly(vinylidene fluoride-co-hexafluoropropylene) is obtained on the receiver. )-copper acetate electrospinning fiber membrane, after electrospinning for 80 minutes, the poly(vinylidene fluoride-co-hexafluoropropylene)-copper acetate electrospinning fi...

Embodiment 3

[0052] 1.1. Preparation of spinning precursor

[0053] Dissolve 20.0g poly(vinylidene fluoride-co-trifluoroethylene) (number average molecular weight: 150,000) and 2.0g tin chloride (mass ratio: 10:1) in N-methylpyrrolidone to prepare poly( Vinylidene fluoride-co-trifluoroethylene) mass ratio concentration is the spinning precursor of 5%;

[0054] 1.2. Preparation of poly(vinylidene fluoride-co-trifluoroethylene)-tin chloride electrospun fiber membrane

[0055] The prepared spinning precursor is electrospun with the copper mesh as the receiver, the voltage of the electrospinning is 30kV, and the distance between the needle and the receiver is 20cm, and poly(vinylidene fluoride-co-trifluoroethylene) is obtained on the receiver. )-tin chloride electrospinning fiber membrane, after electrospinning for 120 minutes, the poly(vinylidene fluoride-co-trifluoroethylene)-tin chloride electrospinning fiber membrane was vacuum-dried at 40°C for 24 hours for later use, and measured The B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com