Method for Improving Bonding Strength of Cemented Carbide and Diamond Coating

A technology of diamond coating and hard alloy, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problem of reducing the performance of coating tools, and achieve nucleation and growth, rough surface The effect of increasing the degree and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Diffusion barrier layers were fabricated using metallic Mo targets.

[0040] First prepare the Mo diffusion barrier layer:

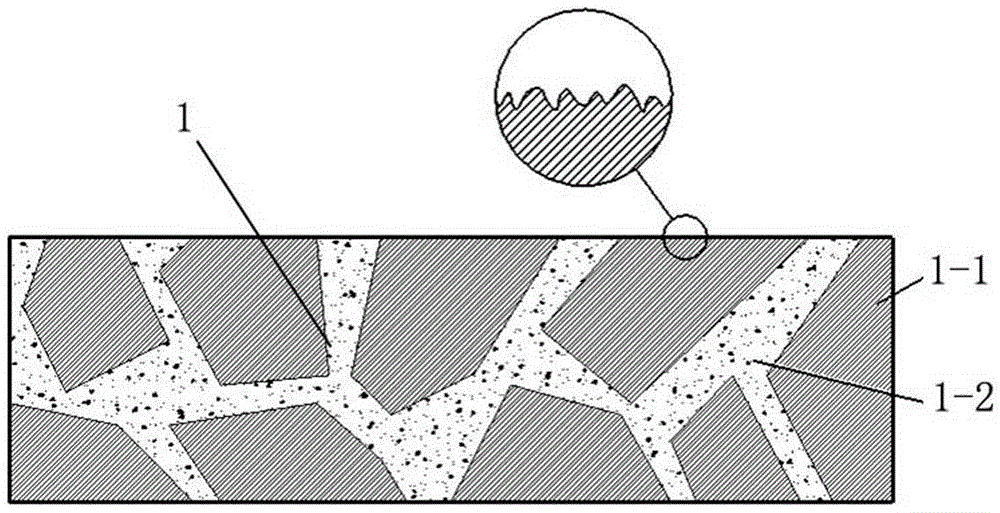

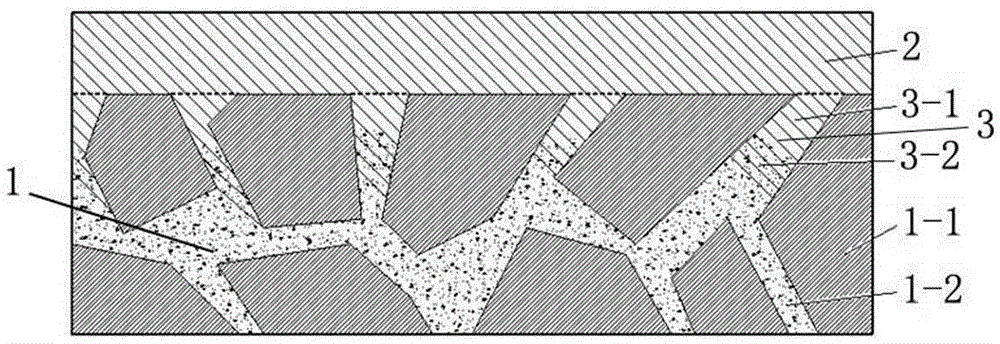

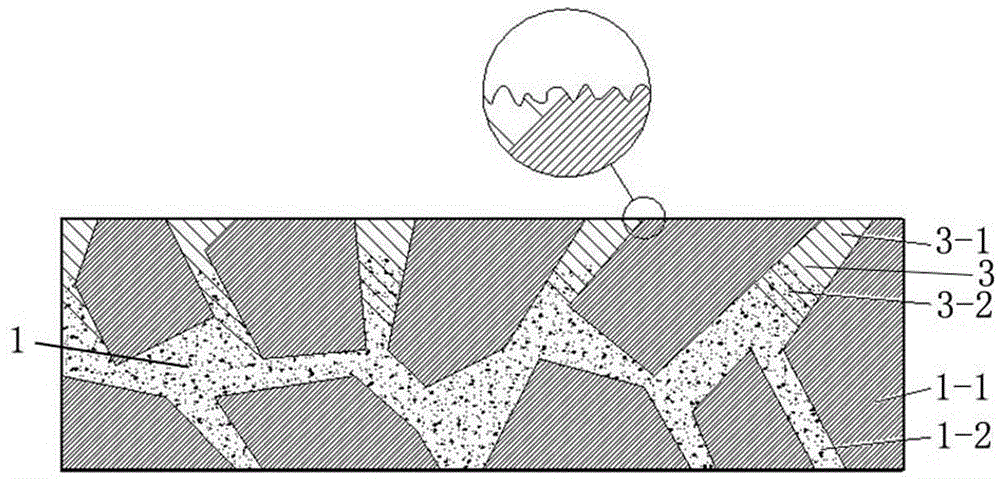

[0041] 1) Grind and roughen the surface of YG6 (WC-6%Co) cemented carbide workpiece 1 with 8 μm diamond powder, then ultrasonically clean it with deionized water and acetone respectively, and dry it with hot air. The surface of the ground cemented carbide workpiece 1 have a certain roughness, such as attached figure 1 shown;

[0042] 2) Place the pretreated cemented carbide workpiece 1 in the double-layer glow plasma surface alloying equipment, adjust the distance between the Mo target and the workpiece 1 to 18 mm, evacuate until the vacuum degree reaches below 1Pa, and pass Ar and CH 4 Mixed gas, the flow rate is Ar:65sccm, CH 4 The content accounts for 2% of Ar gas, the pressure of the vacuum chamber is controlled at 40Pa, the cathode and source power supplies are turned on, the source voltage is adjusted to 500V, and the cathode voltage is ...

Embodiment 2

[0048] Diffusion barrier layer was prepared by using Mo-Ti composite target.

[0049] First prepare the Mo-Ti diffusion barrier layer:

[0050] 1) Grind and roughen the surface of YG8 (WC-8%Co) cemented carbide workpiece 1 with 10 μm diamond powder, then ultrasonically clean it with deionized water and acetone, and dry it with hot air;

[0051] 2) Place the pretreated cemented carbide workpiece 1 in the double-layer glow plasma surface alloying equipment, adjust the distance between the Mo-Ti composite target and the workpiece 1 to 20 mm, and evacuate until the vacuum degree reaches below 1Pa. into Ar and C 2 h 2 Mixed gas, its flow rate is Ar:70sccm, C 2 h 2 Ar content accounts for 3% of Ar gas, the pressure of the vacuum chamber is controlled at 45Pa, the cathode and source power supplies are turned on, the source voltage is adjusted to 300V, and the cathode voltage is adjusted to make it 200V higher than the source voltage. Sputtering, the pre-sputtering temperature is...

Embodiment 3

[0057] Diffusion barrier layers were fabricated using Cr targets.

[0058] First prepare the Cr diffusion barrier layer:

[0059] 1) Grind and roughen the surface of workpiece 1 with 3 μm diamond micropowder, then ultrasonically clean it with deionized water and acetone, and dry it with hot air;

[0060] 2) Place the pretreated workpiece 1 in the double-layer glow plasma surface alloying equipment, use Cr element material as the target material, adjust the distance between the target material and the workpiece 1 to 15mm, and evacuate until the vacuum degree reaches below 1Pa. into Ar and C 3 h 8 The mixed gas, where Ar flow rate is 60sccm, C 3 h 8 The content accounts for 5% of Ar, the pressure of the vacuum chamber is controlled at 50Pa, the cathode and source power supplies are turned on, the source voltage is adjusted to 600V, and the cathode voltage is adjusted to be 300V higher than the source voltage, and the workpiece 1 is pre-sputtered Sputtering, the pre-sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com