A kind of nickel base welding rod for welding Monel alloy

A nickel-based electrode and alloy technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of large welding rod slag shell hardness, uneven welding seam formation, poor crack resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

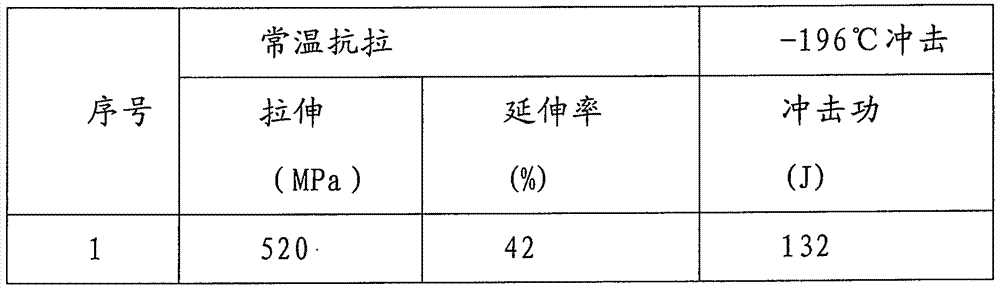

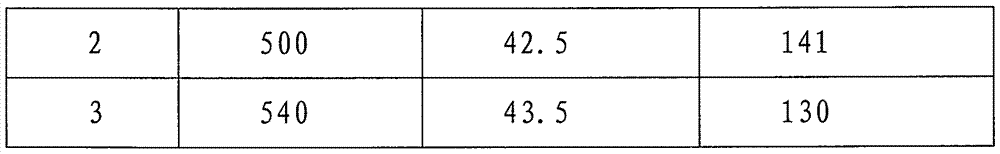

Examples

Embodiment Construction

[0014] Below in conjunction with specific implementation manner is described:

[0015] The purpose of the present invention is to address the defects in the background technology. The weight percentages of the chemical components of the welding core of the present invention are respectively (wt%): C≤0.03%, Mn is 2.00%-5.00%, Si≤0.30%, Ni 63.0-70.0%, Fe≤1.0%, Co≤0.015%, S≤0.010%, P≤0.015%, Ti is 0.010%-0.50%, Al is 0.001%-0.30%, and the rest is Cu; the medicine of the present invention The weight percentage content of each component in the leather is: rutile powder 2% to 5%, marble powder 30% to 45%, fluorite powder 25% to 35%, titanium iron powder 4% to 8%, silicon micropowder 4% to 8%, titanium dioxide 1.5%~3%, soda ash 0.3%~0.6%, electrolytic manganese 3%~5%, potassium titanate 2%~6%, ferrosilicon 1%~3%, silicon zirconium alloy 0.5%~2 % and binder, the total amount of each component is 100%; after mixing the powder of each component in the drug skin in proportion, add the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com