Method for improving nitriding bevel gear wheel part machining precision

A technology for machining bevel gears and parts, applied in the field of machining parts, can solve problems such as reducing gear accuracy, and achieve the effects of eliminating cutting stress, improving machining accuracy, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for improving the machining accuracy of nitriding bevel gear parts of the present invention, it comprises the steps:

[0032] (1) Rough turning blanks, rough machining of bevel gear parts;

[0033] (2) Heat treatment and tempering, the required hardness of the parts is HRC: 28-32, the quenching heating temperature is 840-860°C, heat preservation for 1.5-2h, and then oil quenching, the quenching oil temperature is 40-60°C, and then tempering , the tempering temperature is 640-680°C, keep warm for 2-2.5 hours, and air-cool to room temperature;

[0034] Practice has proved that the nitriding effect of adding heat treatment quenching and tempering process is more obvious than that of the sample without adding quenching and tempering process. Under the same process conditions, the depth of the nitriding layer can be increased by more than 20% after quenching and tempering, and the hardness is also improved.

[0035] (3) Semi-finishing gear blanks, semi-finishing...

Embodiment 2

[0052] In the step 2 heat treatment quenching and tempering, the parts need to be put into an iron box during tempering, and the iron box is covered with charcoal particles to protect the parts to prevent decarburization of the parts.

[0053] In the stress relief annealing of step 5, after the furnace is cooled to 250°C, put the parts into an iron box, then air cool to room temperature, clean the coating before packing, cover the iron box with charcoal particles to protect the parts, and strictly prevent the parts from decarburization and oxidation.

[0054] In the tooth surface nitriding treatment in step 14, the LD-100 3mm deep-well ion nitriding furnace is used, with a rated output DC current of 100A and a voltage of (750-850)V. After the equipment is pre-evacuated to (6.66±0.2)Pa, the (0.25~0.3)L / min ammonia gas, ensure the nitriding under vacuum (665~745)Pa. The working temperature is (500~560)℃, and the deformation can be controlled within 0.003mm~0.008mm; at the same ...

Embodiment 3

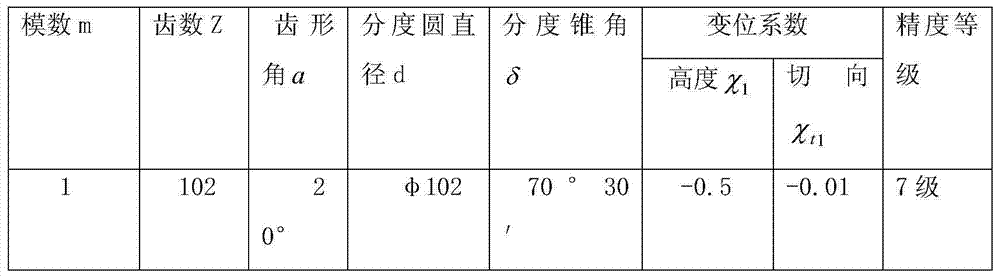

[0057] In this embodiment, the machining of 7-grade precision nitriding straight bevel gear is taken as an example. The material is 38CrMoALA, and the precision grade after nitriding is 7e GB / T10225-1988. The parameters of the cut straight bevel gear are shown in Table 1.

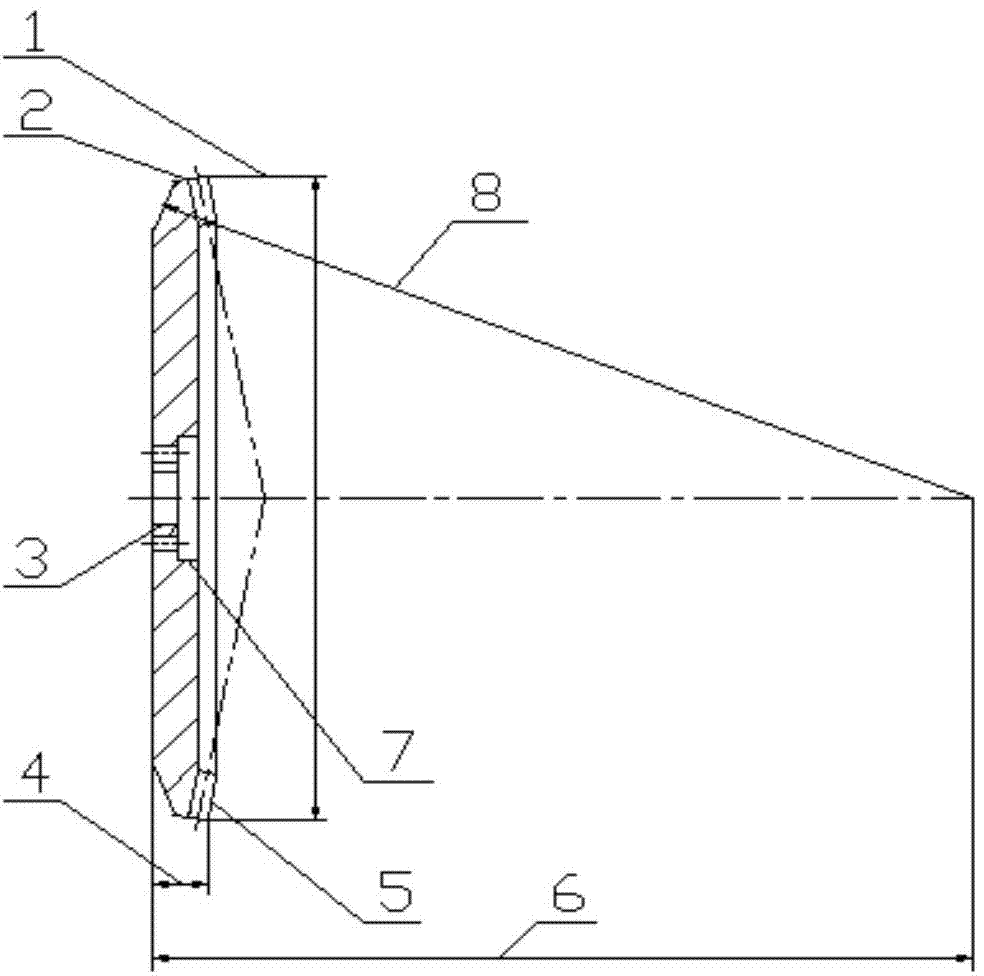

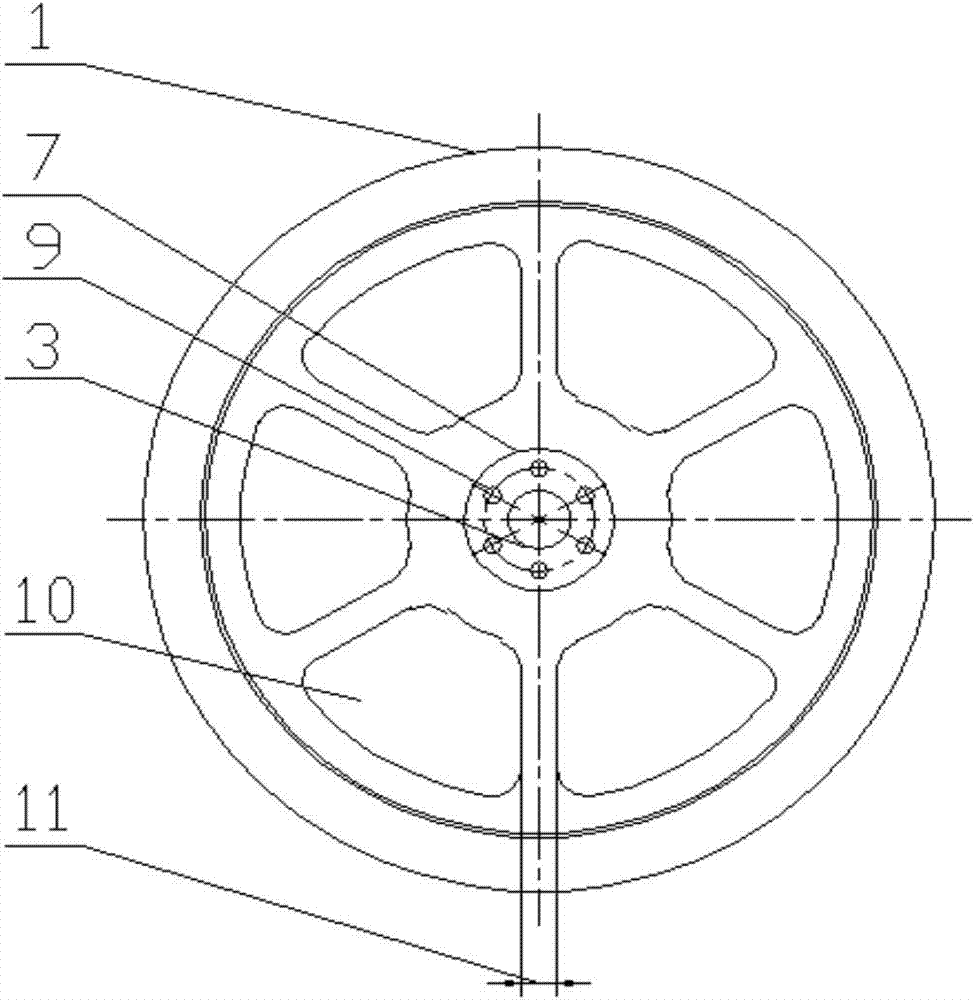

[0058] Part structure such as figure 1 and figure 2 As shown, the diameter of the reference hole 3 is The diameter of addendum circle 1 is Addendum cone angle 5 is 71°20'11"±5', back cone angle 2 is 19°30'±5', and the runout of addendum circle 1, addendum cone 5, and back cone angle 2 relative to reference hole 3 is required The error is 0.01mm, the gear thickness is The verticality of both ends relative to the reference hole 3 is 0.01mm, and the bevel gear intersection size 4 is The diameter of the inner hole 7 is The depth is 6mm, the spherical surface 8 is SR219mm, the dimension 6 from the center of the spherical surface to the end surface is 216±0.05mm, and six square frames 10 are distribute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com