Applications of hydrodeoxygenation catalyst in synthesis of renewable diesel fuel or aviation kerosene

A technology for deoxidation catalyst and regenerated diesel oil, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, refined hydrocarbon oil, etc., can solve the problem of high reaction temperature, achieve good selectivity and excellent operation process Simple, solvent-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

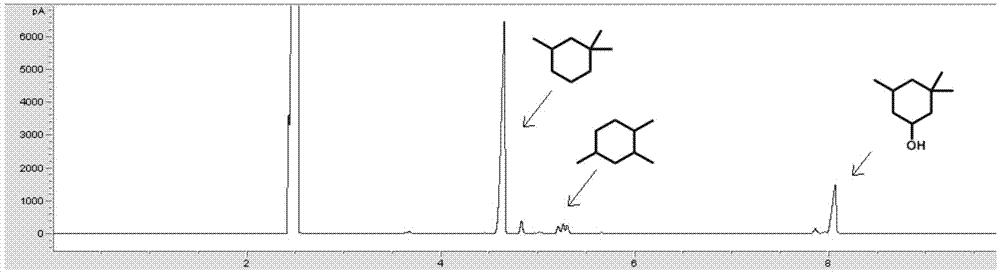

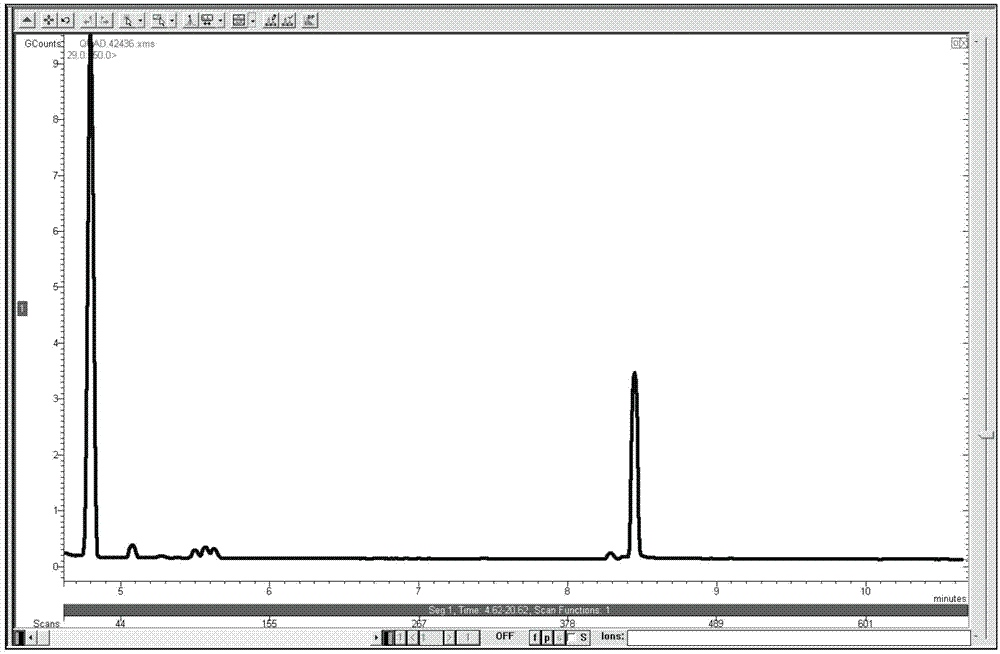

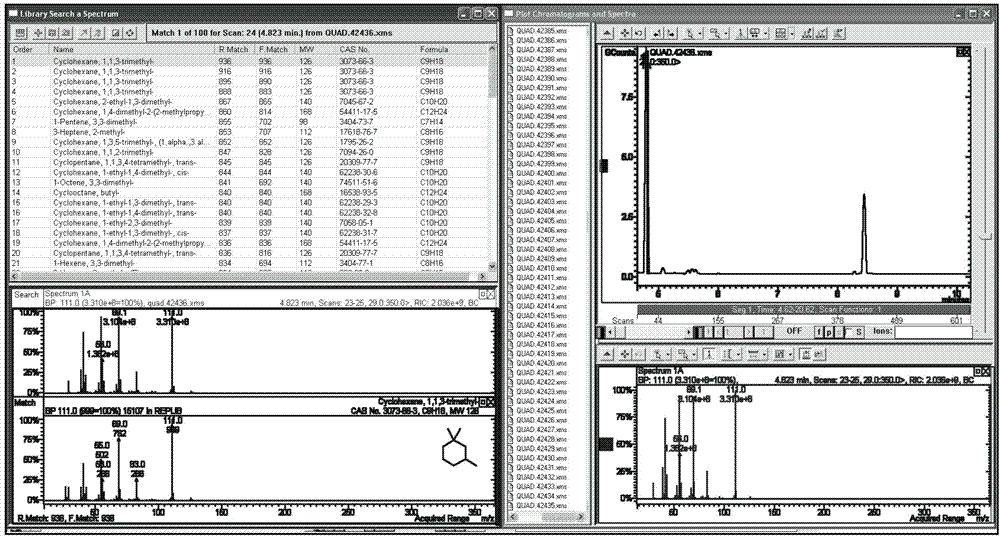

Image

Examples

Embodiment

[0026] 1. Preparation of catalyst:

[0027] (1) Immersion method: Prepare a nickel nitrate solution with a mass concentration of 10%, dilute it according to the saturated water absorption of the carrier, add one of commercial silica and ordered mesoporous silica SBA-15, and then let it stand 2 hours, dry overnight at 120°C, air roast at 500°C for 2 hours, and reduce with hydrogen for 2 hours at 500°C, after the temperature drops to room temperature, feed 1% O 2 / N 2 Passivation can prepare nickel catalysts supported by different carriers (see Table 1, Examples 1 and 2).

[0028] Prepare palladium chloride, ruthenium chloride, chloroplatinic acid, chloroiridic acid, rhodium chloride, nickel nitrate, cobalt nitrate, copper nitrate, iron nitrate solution with a mass ratio of 10%, and add one of them to the commercial Silica, then let it stand for 2 hours, dried overnight at 120°C, calcined in air at 500°C for 2 hours, and reduced with hydrogen at 500°C for 2 hours, after the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com