EFI (exploding foil initiator) chip unit, preparation method of EFI chip unit, and exploding foil initiation device based on chip unit

A chip unit and detonation device technology, which is applied in blasting barrels, offensive equipment, weapon accessories, etc., can solve the problems of being unable to withstand high overload, large volume of detonation device, complex process, etc., and achieve low cost, small size, and reduced process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

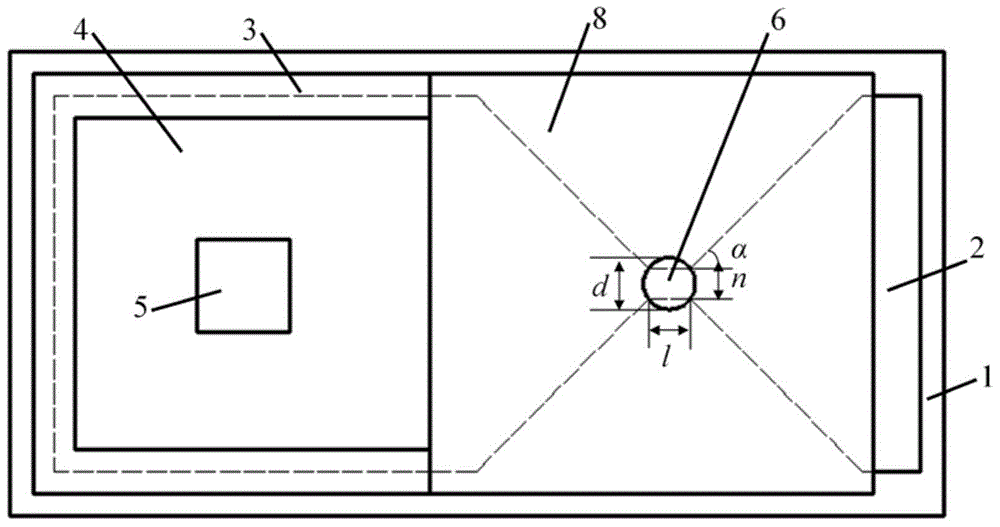

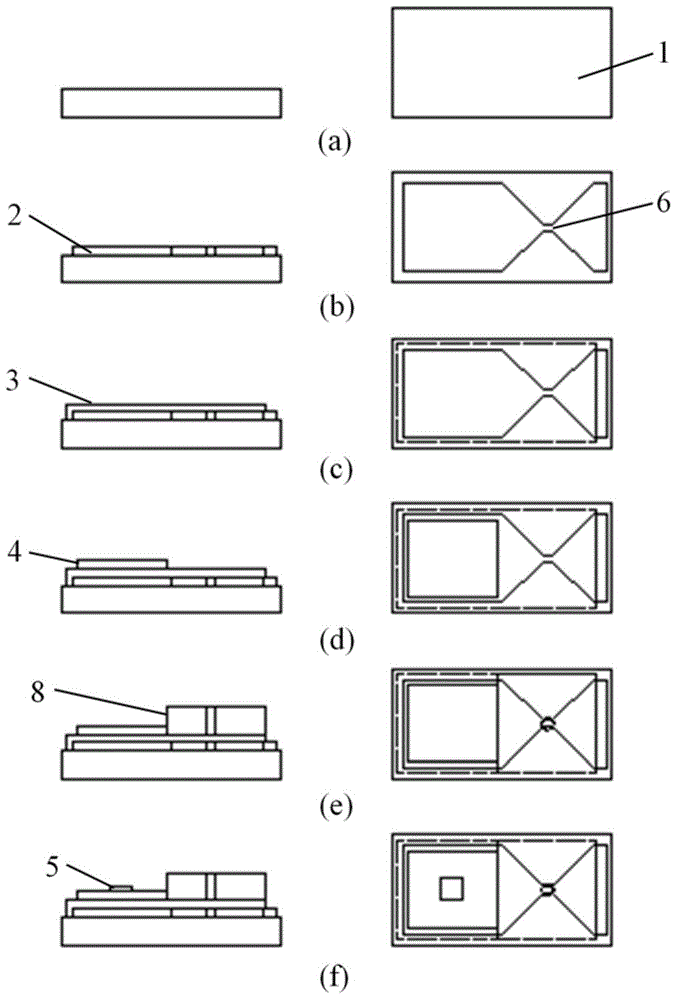

[0024] combine image 3 , the preparation method of EFI chip unit of the present invention, comprises the following steps:

[0025] In the first step, the surface of the ceramic substrate 1 is cleaned, and a Ti layer and a Cu layer are deposited on the surface of the silicon-based substrate by using a photolithographic stripping process and a magnetron sputtering process to form a metal Ti / Cu layer 2, and the metal Ti / Cu Layer 2 is divided into a lower electrode area and a bridge foil area. The lower electrode area is a rectangular structure, and the bridge foil area is a bridge-shaped structure with two ends wide and the middle narrow. The bridge foil area gradually becomes narrow from the wide ends on both sides to the middle Part of the explosion foil 6, wherein one wide end is connected with the lower electrode area;

[0026] In the second step, Chemask is used to protect the wide end of the bridge foil region that is not connected to the lower electrode region, the rest ...

Embodiment 1

[0036] This embodiment integrates the EFI chip unit of the one-shot switch and the acceleration chamber, and the unit includes a ceramic substrate 1, a metal Ti / Cu layer 2, a Parylene C layer 3, an upper electrode Ti / W / Ti / Cu / Au4, a Schottky Second tube 5, Su8 acceleration chamber; metal Ti / Cu layer 2 is set on the ceramic substrate 1, and the metal Ti / Cu layer 2 is divided into a lower electrode area and a bridge foil area, and the lower electrode area has a rectangular structure, The bridge foil area is a bridge-shaped structure with two ends wide and the middle narrow. The narrow part is the explosive foil 6, and the wide end is connected to the lower electrode area. The length l of the explosive foil 6 bridge-shaped area is 0.3mm, and the width n is 0.3mm. A Parylene C layer 3 is arranged on the metal Ti / Cu layer 2, and the Parylene C layer 3 completely covers the lower electrode area and part of the bridge foil area, so that the metal copper layer at one end of the bridge f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com