A sic/al with adjustable thermal expansion 2 (wo 4 ) 3 /al composites

A technology for composite materials and heat regulation, which is applied in the field of composite materials, can solve problems such as low density and obstacles to the development of composite materials, and achieve the effects of improving processing performance, reducing thermal expansion coefficient, and stabilizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

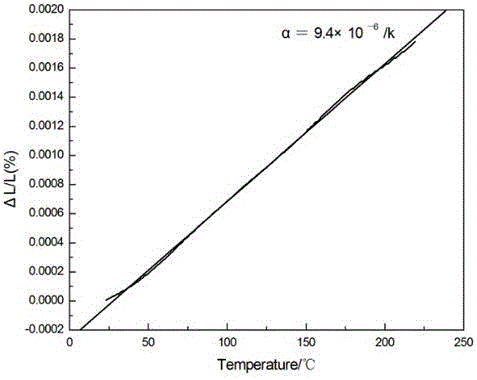

[0026] Raw materials: Al powder, 40% by mass, SiC powder, 50% by mass, Al 2 (WO 4 ) 3 Powder, the mass ratio is 10%.

[0027] Take 0.5g of the above proportioned and uniformly mixed powder, fill it into a mold with a diameter of 10mm, and press it on a tablet press after vibrating and compacting at a pressure of 6MPa. After holding the pressure for 2 minutes, take a sample out of the mold; after the pressing is completed, put it into a vacuum tube Sintering is carried out in the furnace, and the vacuum furnace is heated at a heating rate of 5°C / min. When it rises to 600°C, it is kept for 3 hours, and the flow rate of the protective gas Ar is 1.5ml / s. 2 The flow rate is 0.3ml / s, cooling with the furnace.

[0028] The obtained sample is tested, and the thermal expansion curve is as follows: figure 2 As shown, the average coefficient of thermal expansion of the composite material in the range of 25 to 230°C is 8.6×10 through linear fitting calculation. -6 K -1 .

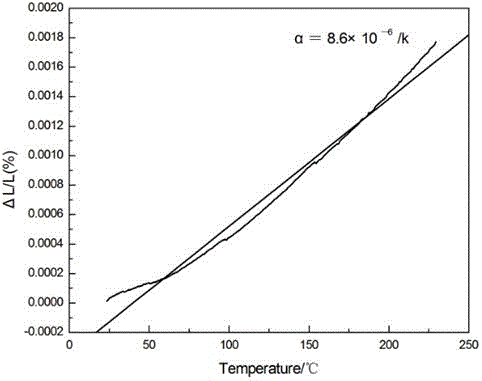

Embodiment 3

[0030] Raw materials: Al powder, 40% by mass, SiC powder, 40% by mass, Al 2 (WO 4 ) 3 Powder, the mass ratio is 20%.

[0031] Take 0.5g of the above proportioned and uniformly mixed powder, fill it into a mold with a diameter of 10mm, and press it on a tablet press after vibrating and compacting at a pressure of 6MPa. After holding the pressure for 2 minutes, take a sample out of the mold; after the pressing is completed, put it into a vacuum tube Sintering is carried out in the furnace, and the vacuum furnace is heated at a heating rate of 5°C / min. When it rises to 600°C, it is kept for 3 hours, and the flow rate of the protective gas Ar is 1.5ml / s. 2 The flow rate is 0.3ml / s, cooling with the furnace.

[0032] The obtained sample is tested, and the thermal expansion curve is as follows: image 3 As shown, the average thermal expansion coefficient of the composite material in the range of 25-230 °C is 7.7×10 -6 K -1 .

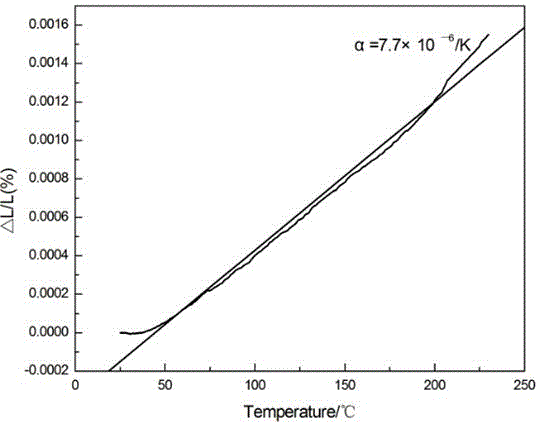

Embodiment 4

[0034] Raw materials: Al powder, 40% by mass, SiC powder, 30% by mass, Al 2 (WO 4) 3 Powder, the mass ratio is 30%.

[0035] Take 0.5g of the above proportioned and uniformly mixed powder, fill it into a mold with a diameter of 10mm, and press it on a tablet press after vibrating and compacting at a pressure of 6MPa. After holding the pressure for 2 minutes, take a sample from the mold; after pressing, put it into a vacuum tube Sintering is carried out in the furnace, and the vacuum furnace is heated at a heating rate of 5°C / min. When it rises to 600°C, it is kept for 3 hours, and the flow rate of the protective gas Ar is 1.5ml / s. 2 The flow rate is 0.3ml / s, cooling with the furnace.

[0036] The obtained sample is tested, and the thermal expansion curve is as follows: image 3 As shown, the average thermal expansion coefficient of the composite material in the range of 25 to 230°C is 4.9×10 -6 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com