Vanadates leadless low-temperature sealing glass material and method for preparing same

A technology for sealing glass and vanadate, which is applied in the field of vanadate-based lead-free low-temperature sealing glass materials and its preparation, to achieve good protection, reduce energy consumption, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Using vanadium pentoxide, boric acid, zinc oxide, tellurium dioxide and alkali metal carbonate as raw materials, calculate the mass percentage of the raw materials according to the mole percentage of each component of the sealing glass, weigh the raw materials, and mix them evenly ;

[0038] 2) Put the uniformly mixed raw materials into a corundum crucible, melt at a melting temperature of 800-900°C, and keep warm for 20-60 minutes;

[0039] 3) Grinding the melted molten glass into powder after casting or water quenching, passing the glass powder particles through a 200-mesh sieve to obtain sealing glass powder.

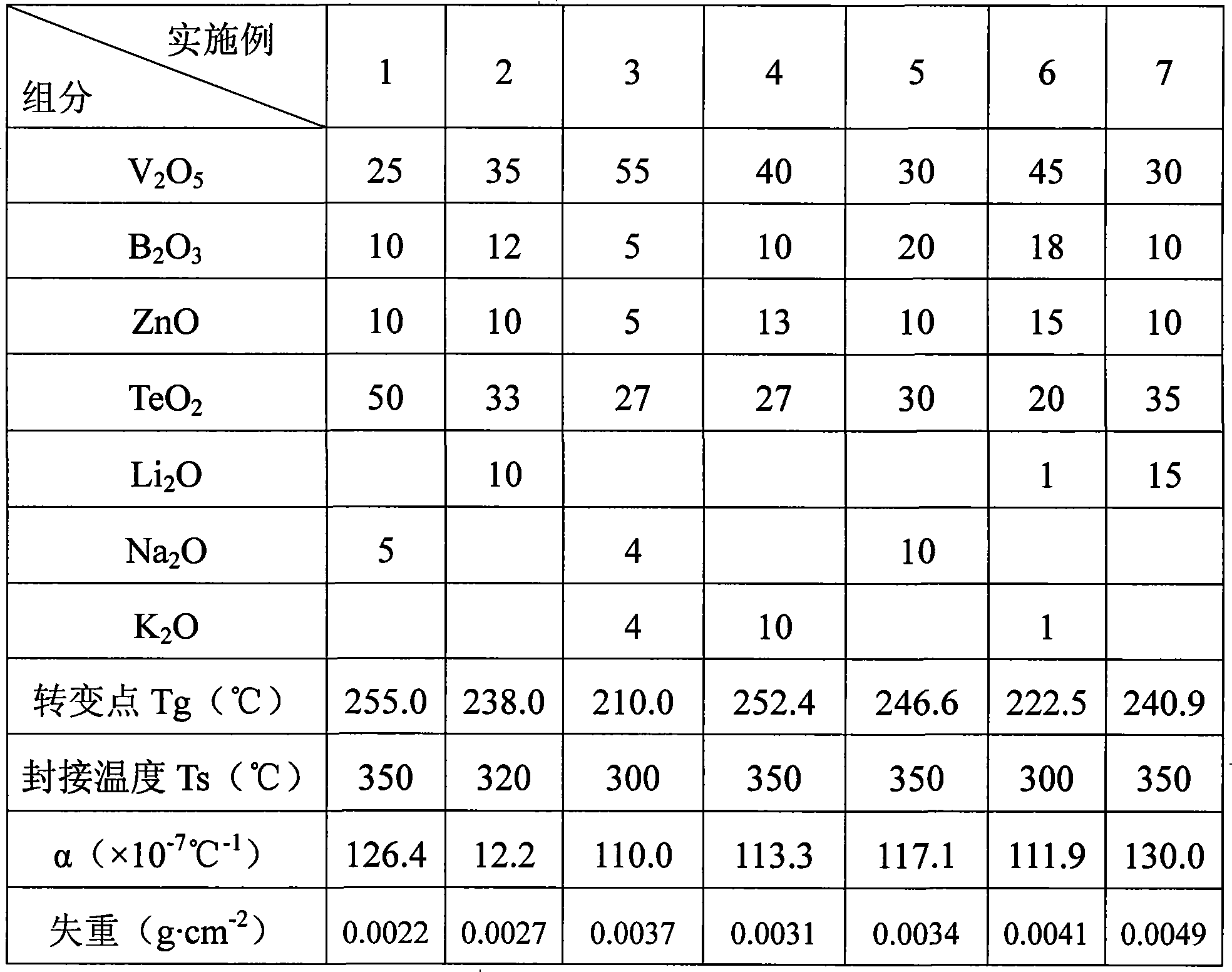

[0040] Table 1 shows the formulations of 7 specific examples of the sealing glass material of the present invention and the test results of the obtained samples, and the compositions are all in mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com