A high-strength synchronous belt and its preparation method

A synchronous belt, high-strength technology, applied in belts, transmission belts, mechanical equipment, etc., can solve the problem of unsatisfactory shear strength, high temperature resistance, wear resistance, reduced transmission power and service life, low strength and elasticity of synchronous belts And other problems, to achieve the effect of good wear resistance, excellent dynamic fatigue performance, excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

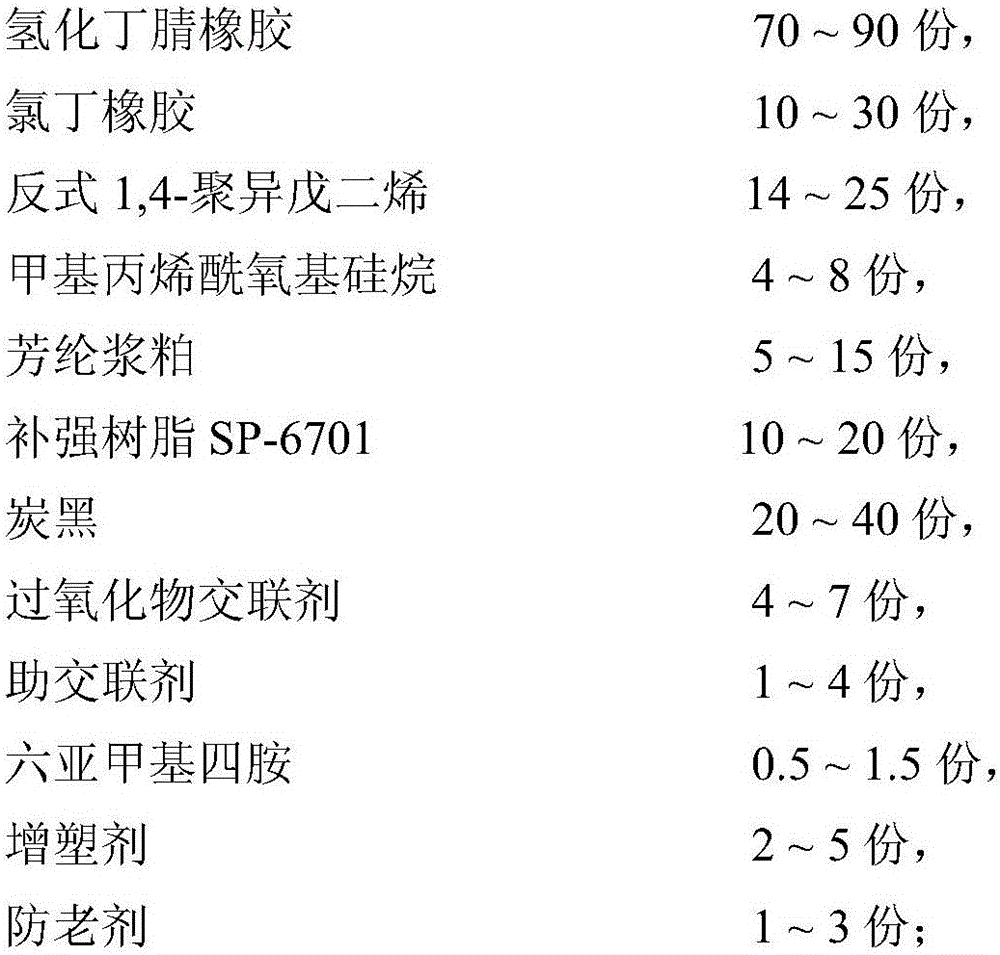

[0040] The high-strength synchronous belt of the present embodiment comprises a synchronous belt skeleton and a film pasted on the outside of the synchronous belt skeleton, and the raw material of the film includes the following components by weight:

[0041]

[0042] The above-mentioned carbon black is a mixture of high wear-resistant carbon black N330 and fast extrusion carbon black N550 at a ratio of 1:1.5 by weight.

[0043] The preparation method of above-mentioned high-strength synchronous belt comprises the following steps:

[0044] (1) Film preparation

[0045] Hydrogenated nitrile butadiene rubber and chloroprene rubber are respectively thinly passed 4 times on the open mill, then the hydrogenated nitrile butadiene rubber after mastication and neoprene are mixed and thinly passed through and beaten triangular bag 10 times;

[0046] Add plasticizer TOTM, antioxidant 4010, trans 1,4-polyisoprene, methacryloxysilane, aramid pulp, carbon black to the mixture of hydrog...

Embodiment 2

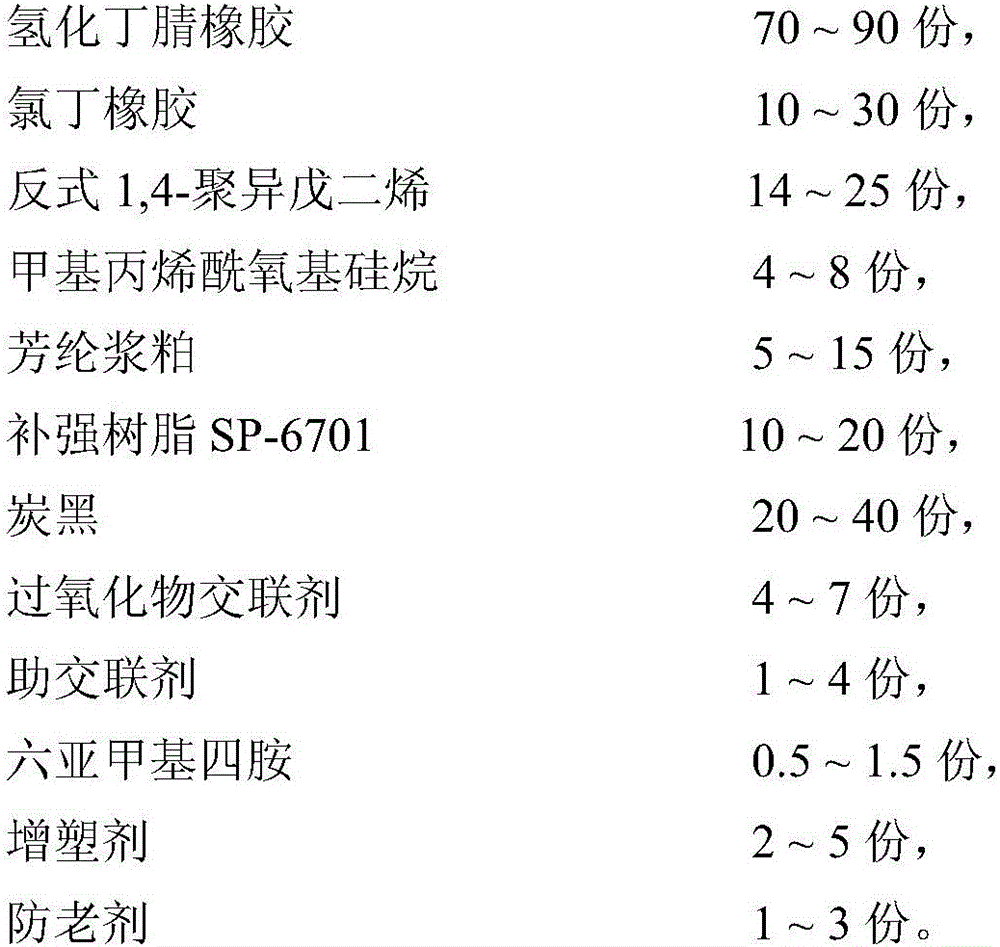

[0056] The high-strength synchronous belt of the present embodiment comprises a synchronous belt skeleton and a film pasted on the outside of the synchronous belt skeleton, and the raw material of the film includes the following components by weight:

[0057]

[0058] The above-mentioned carbon black is a mixture of high wear-resistant carbon black N330 and fast extrusion carbon black N550 at a ratio of 1:0.5 by weight.

[0059] The preparation method of above-mentioned high-strength synchronous belt comprises the following steps:

[0060] (1) Film preparation

[0061] Hydrogenated nitrile butadiene rubber and chloroprene rubber are thinly passed 5 times respectively on the open mill, then the hydrogenated nitrile butadiene rubber after mastication and neoprene are mixed and thinly passed through and beaten triangular bag 12 times;

[0062] Add plasticizer Thiokol TP-95, antioxidant MB, trans-1,4-polyisoprene, methacryloxysilane, aramid pulp to the above mixture of hydroge...

Embodiment 3

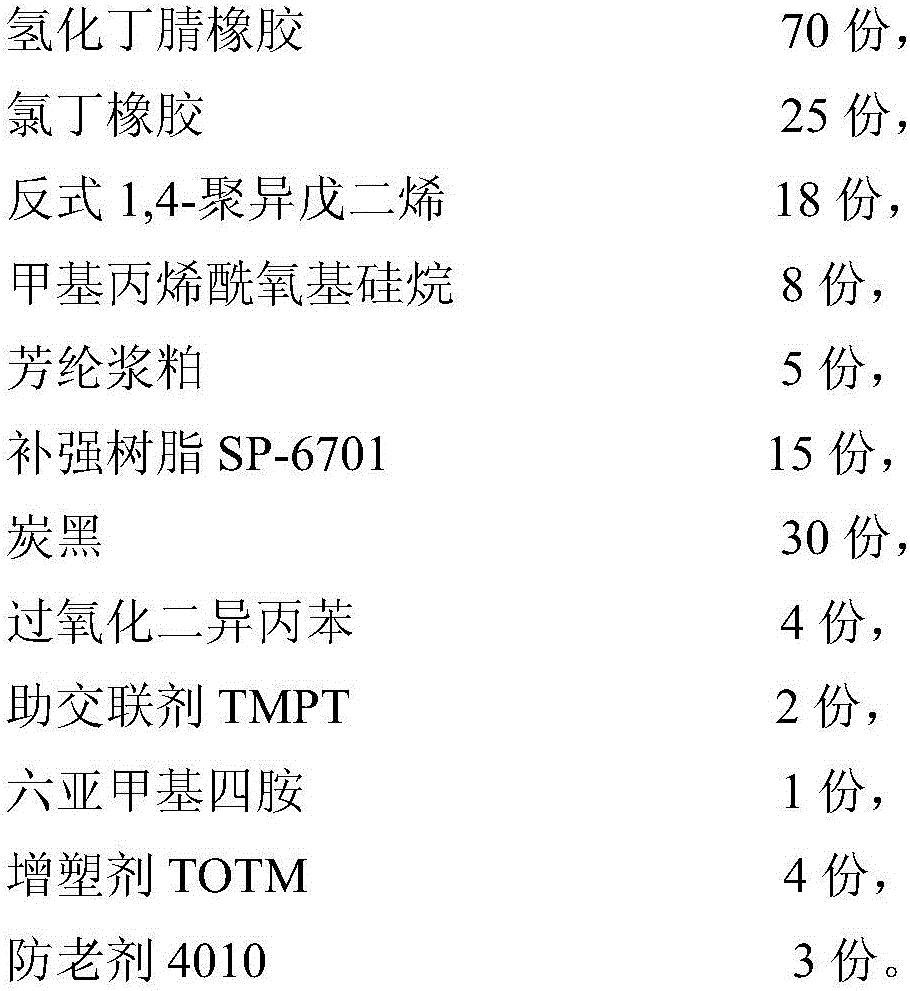

[0069] The high-strength synchronous belt of the present embodiment comprises a synchronous belt skeleton and a film pasted on the outside of the synchronous belt skeleton, and the raw material of the film includes the following components by weight:

[0070]

[0071]

[0072] The above-mentioned carbon black is a mixture of high wear-resistant carbon black N330 and fast extrusion carbon black N550 in a ratio of 1:2 by weight.

[0073] The preparation method of above-mentioned high-strength synchronous belt comprises the following steps:

[0074] (1) Film preparation

[0075] Hydrogenated nitrile butadiene rubber and chloroprene rubber are thinly passed 6 times respectively on the open mill, then the hydrogenated nitrile butadiene rubber after mastication and neoprene are mixed and thinly passed through and beaten triangular bag 11 times;

[0076] Add plasticizer Adiksizer C-9N, antioxidant Naugard445, trans 1,4-polyisoprene, methacryloxysilane, aramid pulp to the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com