A processing technology of super high anti-pilling polyester fabric

A processing technology and anti-pilling technology, applied in the field of finishing and dyeing technology, can solve the problems of reducing friction between fibers, failing to meet testing and wearing, color difference, etc., achieving low requirements for fabric weaving structure, improving wool efficiency and hygroscopicity, Soft and comfortable feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 100

[0048] Embodiment one, 100% polyester fiber knitted fabric processing

[0049] Fabric name: 75D / 72F DTY+75D / 36F DTY double-sided full polyester pigskin cloth

[0050] 1. Enzymatic hydrolysis process for pre-treatment of polyester fabrics:

[0051] Pre-treatment enzymatic hydrolysis to remove fluff and short fibers→cleaning→dyeing

[0052] 1.1 Pretreatment enzymatic hydrolysis process:

[0053]

[0054] 1.2 Cleaning process:

[0055] Hot water washing 2 times: treatment temperature 60°C, treatment time 10 minutes, bath ratio 1:15 (or 1:5 or 1:10 or 1:20);

[0056] Acid neutralization: acetic acid 0.7g / L (or 1.0g / L or 1.2g / L), treatment condition 40℃*6 minutes;

[0057] Wash in cold water 1 time.

[0058] 1.3 Conventional process dyeing.

[0059] 1.4 Points to note: Before dyeing polyester fabrics, unreacted finishing agents must be cleaned in strict accordance with the process, so as not to affect the dyeing quality. Inadequate washing will result in insufficient dyeing...

Embodiment 2

[0069] Embodiment two, polyester fiber and cotton fiber blended knitted fabric processing

[0070] Fabric name: 32ST / C65 / 35+100D / 96F DTY+10S polyester-cotton blended terry cloth

[0071] 1. Pre-treatment enzymatic hydrolysis process of polyester blended fabrics:

[0072] Pre-treatment enzymatic hydrolysis to remove short fluff→cleaning→polyester dyeing→(cotton fiber biological washing)→cotton dyeing

[0073] Process Description: Polyester-cotton blended fabrics, because the special anti-pilling finishing ZS-PILL for polyester has an effect on polyester fibers, but the direct effect on cotton fibers is not obvious; if the anti-pilling test of the fabric after pre-treatment is not OK, you can choose After polyester is dyed, bio-washing is carried out for the pilling performance of cotton fiber. (Specifically, it can be decided whether to do biological washing processing according to the raw material performance of cotton yarn and spinning method).

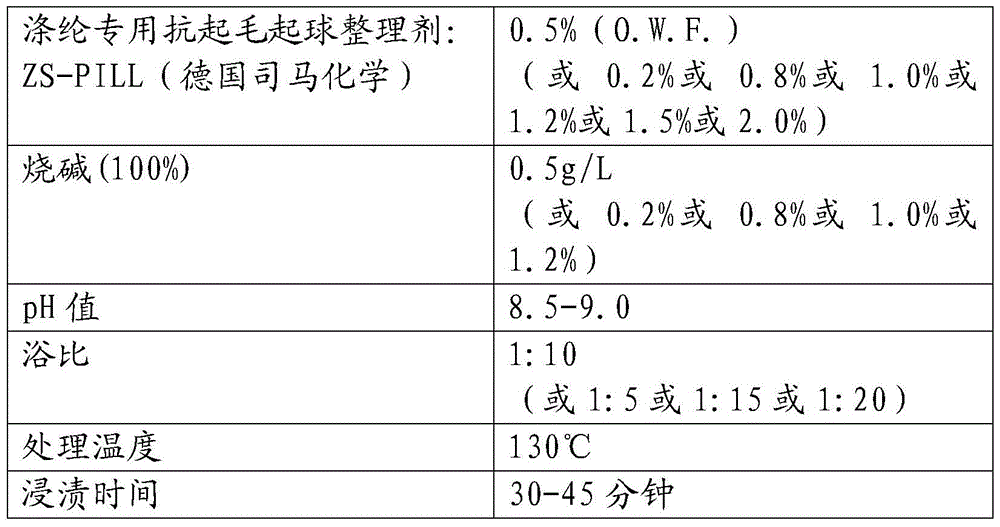

[0074] 1.1 Pretreatment en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com