Double-surface grinding and double-surface polishing high-efficiency ultraprecise processing method for large-sized A-directional sapphire mobile phone screen

A technology of ultra-precision machining and double-sided grinding, which is applied to polishing compositions containing abrasives, stone processing equipment, grinding/polishing equipment, etc. It can solve the problems of high processing costs and low processing quality of sapphire mobile phone screens, and achieve Good processing quality, eliminate mechanical processing damage layer, and reduce the effect of surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A high-efficiency ultra-precision machining method for double-side grinding and double-side polishing of a large-size sapphire mobile phone screen, which includes the following steps:

[0055] (1) Orientation: Select the sapphire A surface with better wear resistance of the sapphire crystal, and perform orientation to ensure that the cut-out mobile phone screen is A-oriented;

[0056] (2) Slicing: According to the shape and size of the mobile phone screen, slice the sapphire crystal. The thickness of the sliced sapphire crystal is 50-70 microns thicker than that of the mobile phone screen, and the length and width are consistent with the mobile phone screen;

[0057] (3) Double-sided grinding: use double-sided grinding equipment to perform double-sided grinding on the sliced sapphire mobile phone screen (2); the specific operation method of double-sided grinding is:

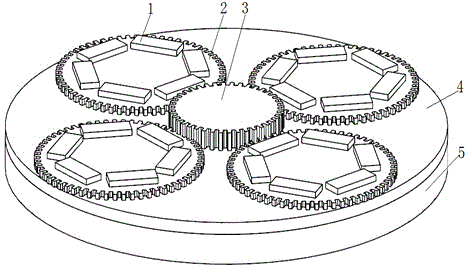

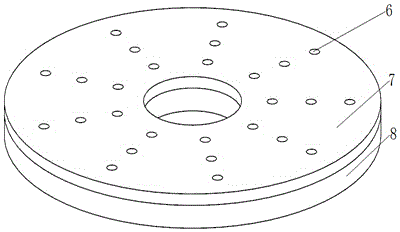

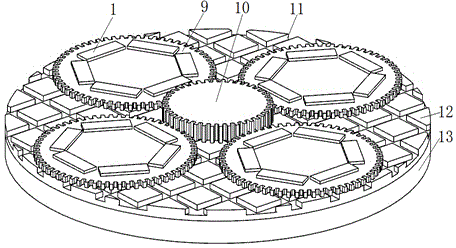

[0058] (3-1) If figure 1 and figure 2 As shown, the lower grinding pad (4) and the upper grindin...

Embodiment 2

[0086] A high-efficiency ultra-precision machining method for double-side grinding and double-side polishing of a large-size sapphire mobile phone screen, which includes the following steps:

[0087] (1) Orientation: Select the sapphire A surface with better wear resistance of the sapphire crystal, and perform orientation to ensure that the cut-out mobile phone screen is A-oriented;

[0088] (2) Slicing: According to the shape and size of the mobile phone screen, slice the sapphire crystal. The thickness of the sliced sapphire crystal is 50-70 microns thicker than that of the mobile phone screen, and the length and width are consistent with the mobile phone screen;

[0089] (3) Double-sided grinding: Use double-sided grinding equipment to perform double-sided grinding on the sliced sapphire crystal; the specific operation method of double-sided grinding is:

[0090] (3-1) If figure 1 and figure 2 As shown, the lower grinding pad (4) and the upper grinding pad (7) contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness uniformity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com