Lateral epitaxial technique based longitudinal structure AlGaN/GaN HEMT device and manufacture method thereof

A vertical structure, lateral epitaxy technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as lattice damage, large leakage, complexity, etc., to reduce the impact of leakage, reduce production costs, Effect of Simplified Growth Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

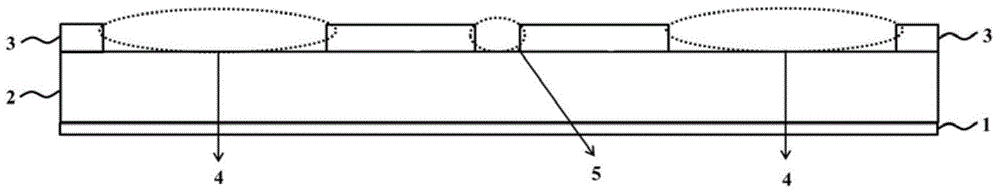

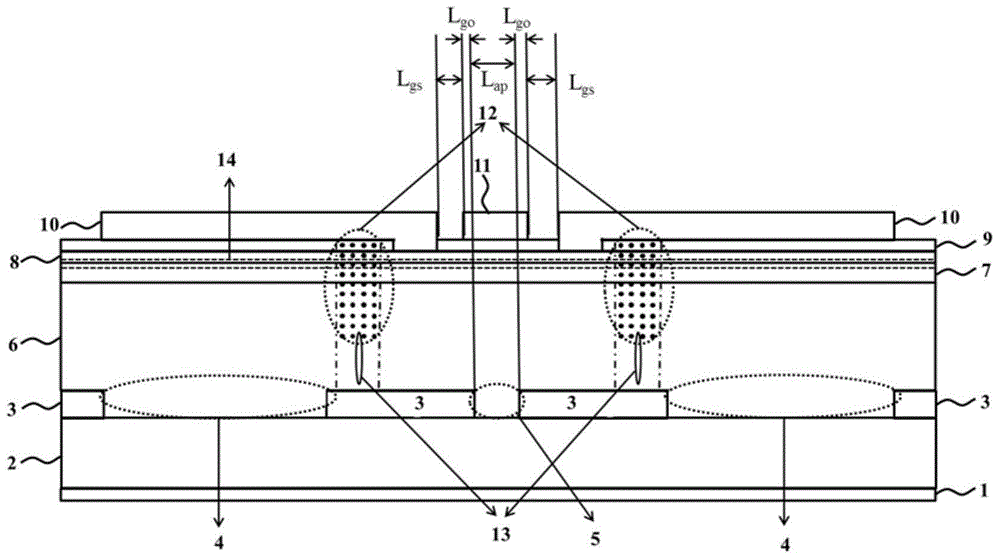

[0044] The embodiment of the present invention discloses a vertical structure AlGaN / GaN HEMT device based on lateral epitaxy technology, including a substrate and a current blocking layer formed on the substrate, and a current conduction layer is formed on the current blocking layer. The vertical structure AlGaN / GaN HEMT device further includes an epitaxial layer grown laterally on the current blocking layer.

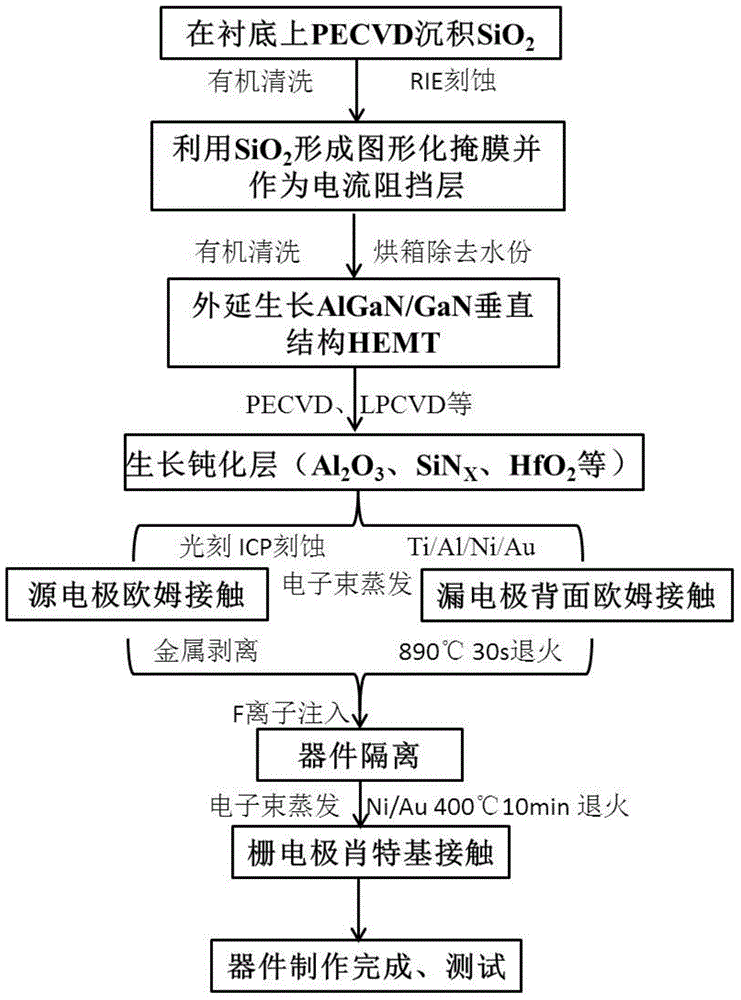

[0045] Preferably, the epitaxial layer includes a healing intrinsic GaN layer, an intrinsic GaN layer and an intrinsic AlGaN layer sequentially formed on the current blocking layer; the vertical structure AlGaN / GaN HEMT device also includes the intrinsic The AlGaN layer forms a source electrode in ohmic contact, a gate electrode disposed on the intrinsic AlGaN layer through a passivation layer, and a drain electrode formed on the bottom surface of the substrate. The passivation layer material can be selected from but not limited to Al 2 o 3 , silicon nitride (SiN x )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com