Preparation method and hole sealing method of magnesium alloy surface ceramic coating

A ceramic film layer and magnesium alloy technology, applied in anodic oxidation, etc., can solve the problems of magnesium alloy surface corrosion, poor high temperature resistance, high equipment requirements, etc., achieve good corrosion resistance, good film compactness, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

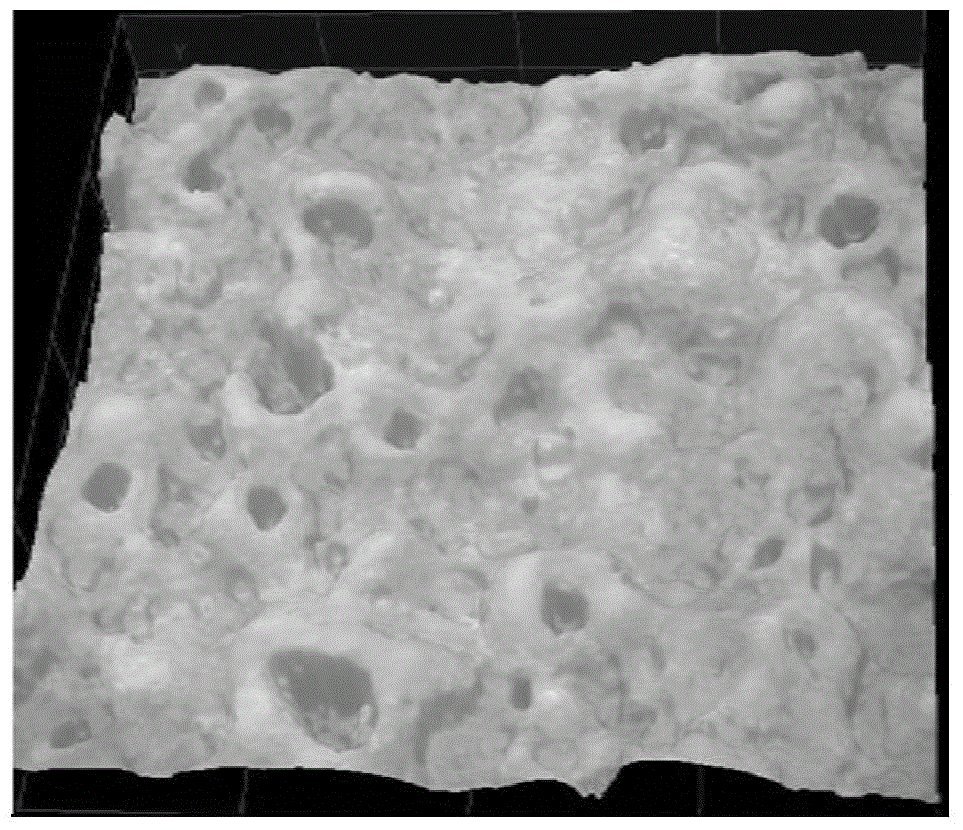

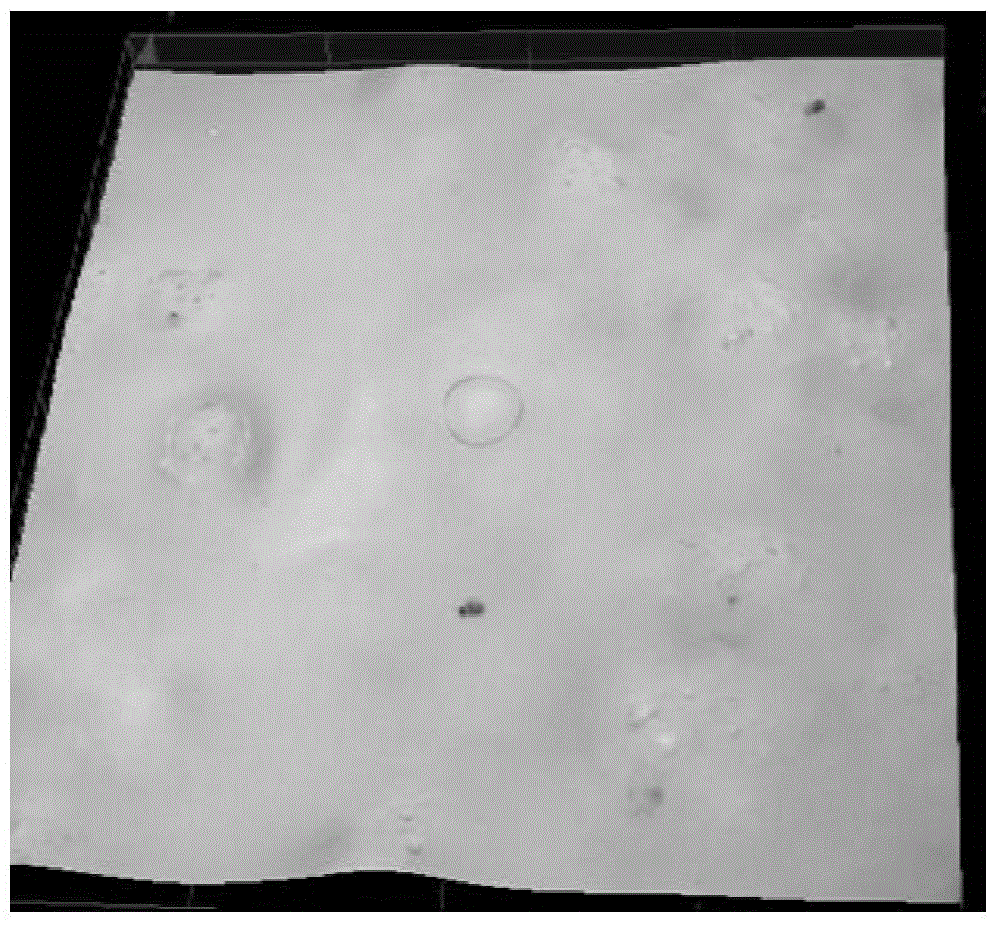

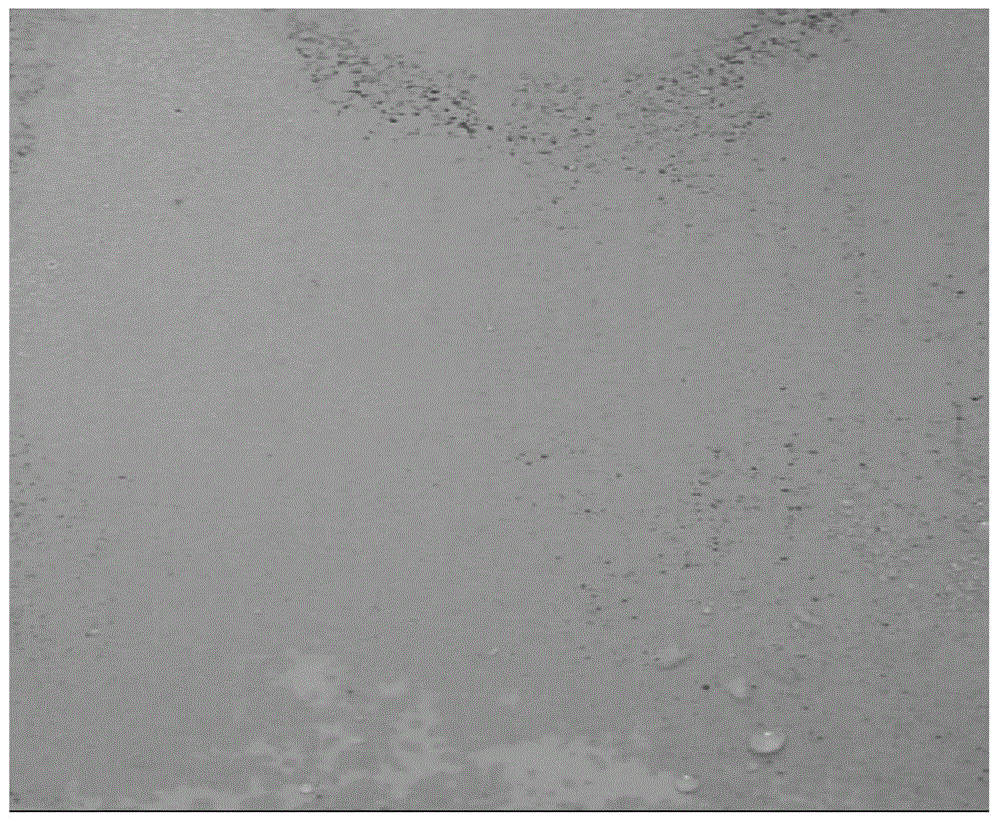

Image

Examples

Embodiment 1

[0026] The workpiece to be processed is a magnesium alloy AM80 plate, the size is 100mm×75mm×10mm, and it is hung at 10% (W / W) HNO 3 Soak in the solution for 1 minute, take it out and wash it with water, put it in the oxidation tank as the anode, and the electrolyte composition is: PO 4 3- 0.2mol / l, F - 0.2mol / l, NH 4 + 0.95mol / l, Na + 0.1mol / l, triethanolamine 0.3mol / l; power supply adopts DC waveform, set oxidation current to 3A, frequency to 50Hz, duty cycle to 30%, temperature to 15°C, under compressed air stirring, oxidation time to 10 minutes, voltage to 400V, oxidation After finishing, take out the workpiece, rinse it with clean water, and soak it in hot water at 60°C for 5 minutes; dry it with compressed air, and then place the workpiece in a container filled with nano-SiO 2 In the vacuum container of the ceramic sealing liquid, the dispersant of the sealing liquid is isopropanol, with a solid content of 25% (mass percentage), vacuumize until there are no bubb...

Embodiment 2

[0029]The workpiece to be processed is a magnesium alloy ZK80 plate with a size of 100mm×75mm×10mm. The surface is sandblasted with 220 mesh glass sand, washed with water after hanging up, and placed in an oxidation tank as an anode. The electrolyte composition is: PO 4 3- 0.15mol / l, F - 0.25mol / l, NH 4+ 0.95mol / l, Na + 0.1mol / l, triethanolamine 0.3mol / l, urotropine 0.15mol / l; the power supply adopts a single pulse waveform, the oxidation current is set to 3A, the duty cycle is 50%, the frequency is 200Hz, the temperature is 20℃, under the stirring of compressed air , the oxidation time is 10 minutes, and the oxidation voltage is 390V. After the oxidation, the workpiece is taken out, rinsed with clean water, and the surface moisture is dried with compressed air; then the workpiece is suspended in a container filled with nano-SiO 2 In the vacuum container of the ceramic sealing liquid, the dispersant of the sealing liquid is polyethylene glycol, with a solid content of 2...

Embodiment 3

[0032] The workpiece to be processed is a magnesium alloy Az91 die casting with a surface area of 5dm 2 , the surface is sandblasted with 220-mesh glass sand, washed with water after being hung up, placed in an oxidation tank as an anode, and the electrolyte composition is: PO 4 3- 0.2mol / l, NH 4 + 0.95mol / l, triethanolamine 0.25mol / l, glycerin 0.1mol / l; the power supply adopts DC waveform, the oxidation current is set to 4A, the frequency is 1000Hz, the duty cycle is 40%, the temperature is 20°C, the oxidation time is 5 under compressed air stirring Minutes, voltage 380V, take out the workpiece after oxidation, rinse with clean water, soak in hot water at 60°C for 5 minutes; blow dry with compressed air, and then place the workpiece in a container filled with nano-SiO 2 In the vacuum container of the ceramic sealing liquid, the dispersant of the sealing liquid is isopropanol, the solid content is 20% (mass percentage), vacuumize until no bubbles emerge from the sealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com