Portable all-solid hydrogen production material as well as preparation method and application thereof

A portable, hydrogen material technology, applied in the production of hydrogen and other directions, can solve the problems of reducing the hydrogen production per unit mass of materials, inconvenient carrying, storage, transportation, and inability to use existing systems, and achieve the reduction of actual water consumption, Hydrogen source and the effect of miniaturization, portability and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix 1g Al with 8.5g Na 2 B 4 o 7 10H 2O (the molar ratio is 5:3) was added into the mortar and ground into a uniform powder, and then the two were mixed evenly, and dichloromethane was added, and the composite material was obtained by ultrasonic vibration. Put the composite material into a flask, heat it to 55°C, and collect the hydrogen gas generated by the drainage and gas collection method. 1.2L hydrogen gas can be released within 25 minutes, which is 98% of the theoretical hydrogen production.

Embodiment 2

[0041] Mix 1g Mg with 3.4g AlCl 3 ·6H 2 O (3:1 molar ratio) was added into a mortar and ground into a uniform powder, and then the two were mixed evenly, and the composite material was obtained by ball milling under a hydrogen atmosphere. The composite material was heated to 150°C, and the generated hydrogen was collected by the drainage and gas collection method, and 0.78L (0.066L / g) of hydrogen was generated within 10 minutes, which was equivalent to 84% of the theoretical hydrogen production.

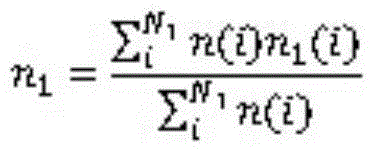

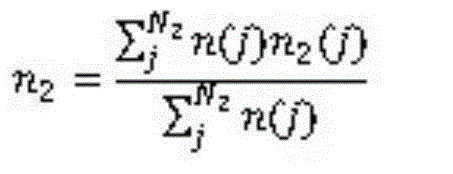

[0042] In the same way, calcium Ca, lithium Li, sodium Na, and potassium K can also be used as solid matter that reacts with water to emit hydrogen, and the method for the molar ratio of solid matter and water-containing solid matter that reacts with water to emit hydrogen is according to the method described in the summary of the invention The method is determined.

Embodiment 3

[0044] 1g CaH 2 with 2.2g Na 4 P 2 o 7 10H 2 O (molar ratio 5:1) was added into a mortar and ground into a uniform powder, and then the two were mixed evenly, and cyclohexane was added to assist stirring evenly, and the composite material was obtained after removing the solvent. The composite material was put into a flask, heated to 40°C, and the generated hydrogen was collected by the drainage and gas collection method. 0.922L of hydrogen was generated within 30 minutes, which was 88% of the theoretical hydrogen production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com