Method and device for realizing low-cost tunable semiconductor laser based on reconstruction-equivalent chirp and series/parallel hybrid integration technologies

An equivalent chirp and laser technology, applied in the field of optoelectronics, can solve the problems of increasing laser cost, reducing laser performance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] [Example 1] 3X4 segment tunable semiconductor laser based on series / parallel hybrid integration:

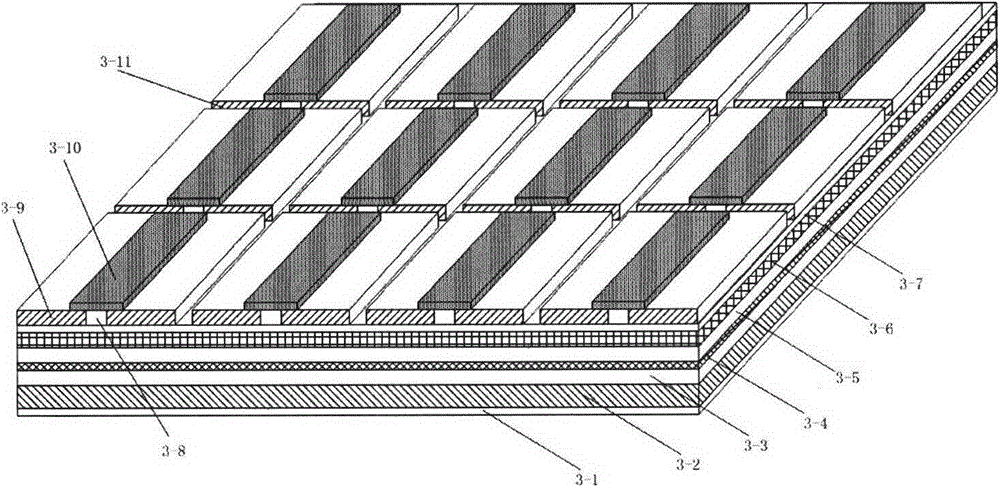

[0029] Such as figure 1 As shown, the epitaxial material of the device is described as follows: First, an N-type InP buffer layer (thickness 200nm, doping concentration of about 1.1X10 18 cm -2 ), 100nm thick amorphous doped lattice matching InGaAsP waveguide layer, strained InGaAsP multi-quantum well layer (optical fluorescence wavelength 1.52 microns, 7 quantum wells: well width 8nm, 0.5% compressive strain; barrier width 10nm, lattice matching material ), 70nm thick InGaAsP grating material layer. Then, a mask plate containing the sampling period distribution required by the equivalent grating is fabricated using common microelectronics technology. Next, the grating structure is produced by sampling mask and holographic interference exposure, and then the second epitaxial 100nm thick P-type lattice matching InGaAsP waveguide layer (the doping concentration is about 1...

example 2

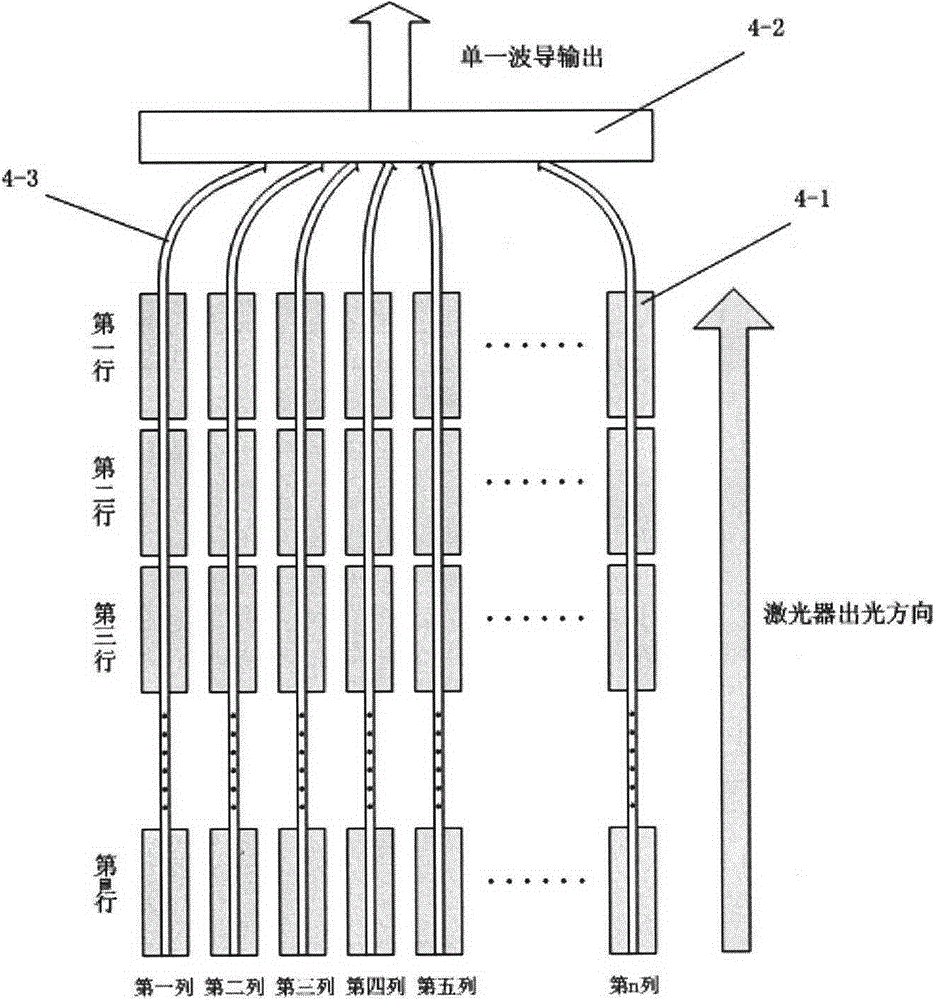

[0033] [Example 2] Multi-segment tunable semiconductor laser based on series / parallel hybrid integration:

[0034] Such as figure 2 As shown, the 3X4 segment tunable laser in Example 1 can be extended to an mxn segment tunable laser including m rows and n columns of lasers, and the material structure is the same as that of Example 1, wherein there are all between rows and columns and between columns and columns Make a 75um electrical isolation slot. In the process of making electrical isolation, the ohmic contact layer InGaAsP in the corresponding area of the laser is first etched away by dry or wet methods, and then ion implantation is performed in this area, and then the insulating material SiO2 with a thickness of 300nm is covered. The SiO over the ridge waveguide is then 2 The material is etched away and the P-type electrode on the front of the laser is made. The N-type electrode on the back is fabricated after the laser substrate is thinned. There are anti-reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com