Automatic forming production line and automatic forming production technology for narrow-mouth circular ceramic container product

A technology for automatic molding and ceramic containers, which is applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc. It can solve the problems of difficult grinding, laborious movement, and low degree of automation, so as to achieve easy grinding and prevent adhesion. Together, avoid the effect of chaining together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

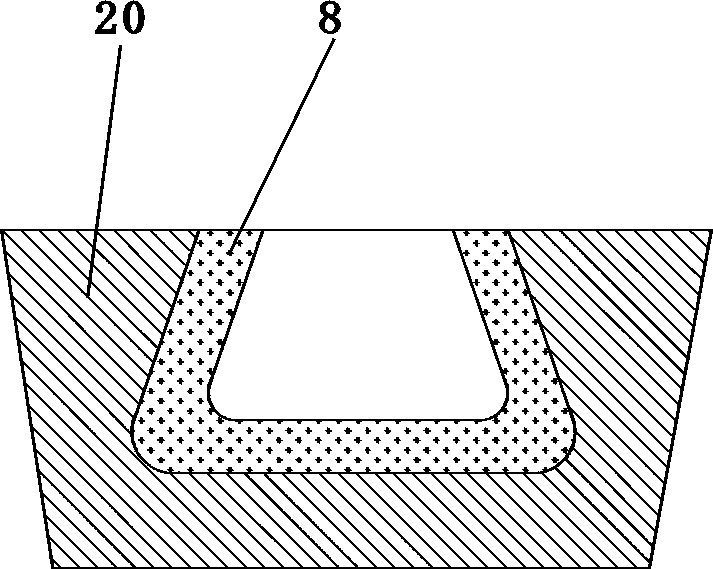

[0054] image 3 , Figure 4 , Figure 5 , Figure 6 The shown automatic molding production line for narrow-mouth circular ceramic container products includes a circulation guide rail 11 and an oven 12, the circulation guide rail 11 passes through the inner cavity of the oven 12, and a plurality of carrying trolleys 13 are installed on the circulation guide rail 11, each carrying A mold is placed on the trolley 13, and the mold is divided into a circular outer mold cover 2 and a circular inner mold core 3, and the circular inner mold core 3 is placed in the circular outer mold cover 2, and the circular outer mold cover 2 includes The peripheral wall 22 of the outer mold casing and the bottom wall 21 of the outer mold casing.

[0055] Next to the path where the mold moves along the circular guide rail, there are mud billet placement mechanism 14, rolling forming mechanism 15, and green body take-out mechanism 16 (the moving direction of the mold along the circular guide rail ...

Embodiment 2

[0062] An automatic molding production process for narrow-mouth circular ceramic container products, which adopts the automatic molding production line for narrow-mouth circular ceramic container products of Embodiment 1, and includes the following steps in sequence:

[0063] (1) The carrying trolley 13 drives the mold to move along the circular guide rail 11. The mold includes a circular outer mold sleeve 2 and a circular inner mold core 3. The circular inner mold core 3 is placed inside the circular outer mold sleeve 2. When the mold passes through When next to the mud billet placement mechanism 14, the mud billet placement mechanism 14 puts the round cake-shaped mud billet into the mould;

[0064] (2) The carrying trolley 13 continues to drive the mold to move along the circular guide rail 11. When the mold passes by the rolling forming mechanism 15, the rolling forming mechanism 15 rolls the round cake-shaped mud into a circular container with a small top and a large bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com