A kind of composite diaphragm for lithium selenium battery and preparation method thereof

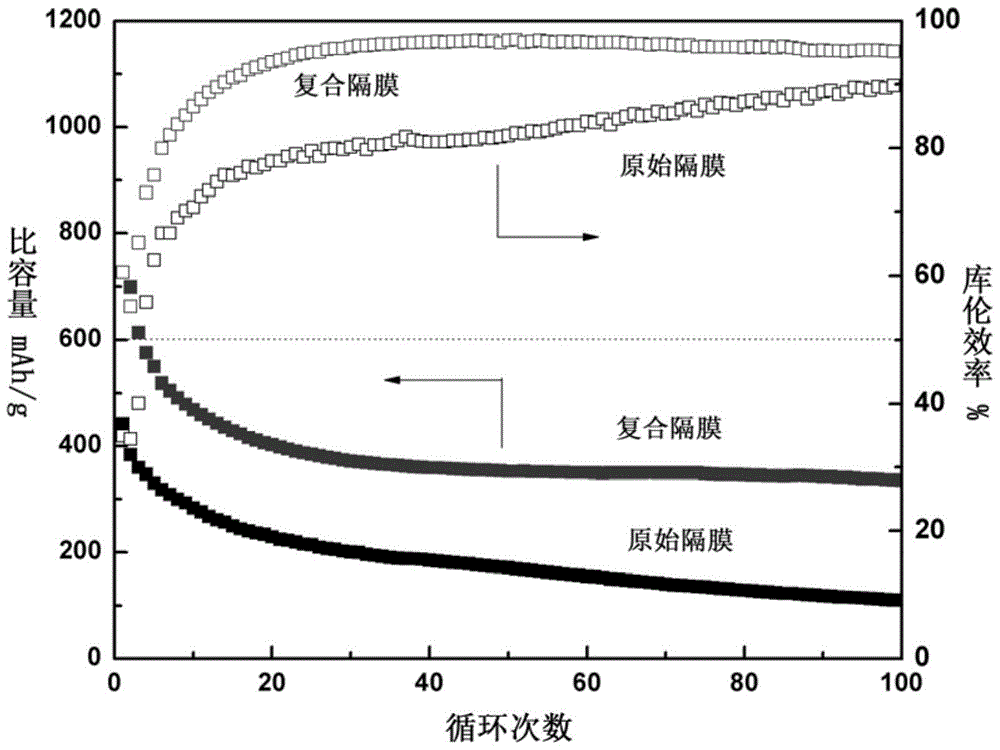

A composite diaphragm and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of reducing the selenium content in the selenium positive electrode and complicated process, so as to eliminate surface passivation, increase discharge capacity, and improve cycle performance and the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

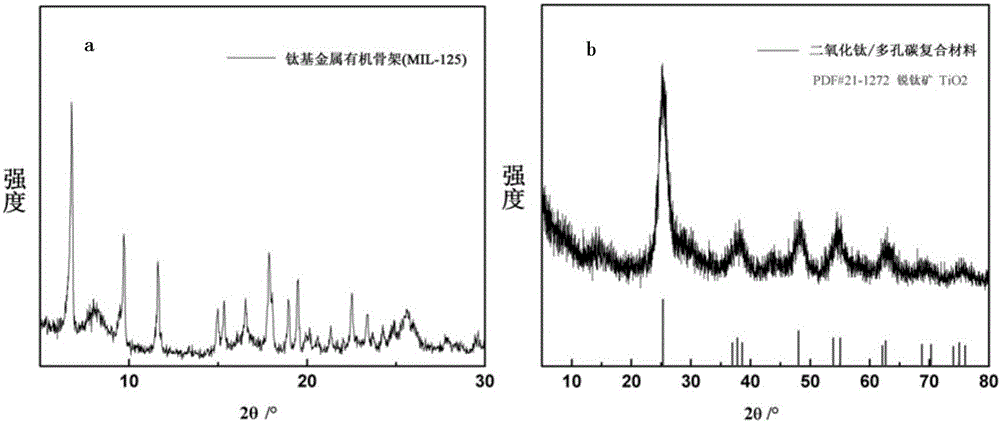

[0034] 1) Preparation of titanium-based metal organic framework:

[0035] Tetrabutyl titanate and terephthalic acid are added in a 1:4 ratio (substance amount ratio) into a mixed solvent with a volume ratio of methanol and dimethylformamide of 1:9, and the concentration of titanium salt in the organic solvent is 0.075 mol L -1 After mixing uniformly, transfer to a polytetrafluoroethylene autoclave, heat up to 150°C and keep it at this temperature for 20h for solvothermal reaction. After the reaction, cool to room temperature at a temperature drop rate of 1°C / min at 10 000r Centrifugal filtration at speed per minute, alternating washing with methanol and deionized water 3 times, drying at 60°C, and transferring to a vacuum drying oven at 180°C for 72h activation, thereby obtaining a titanium-based metal organic framework;

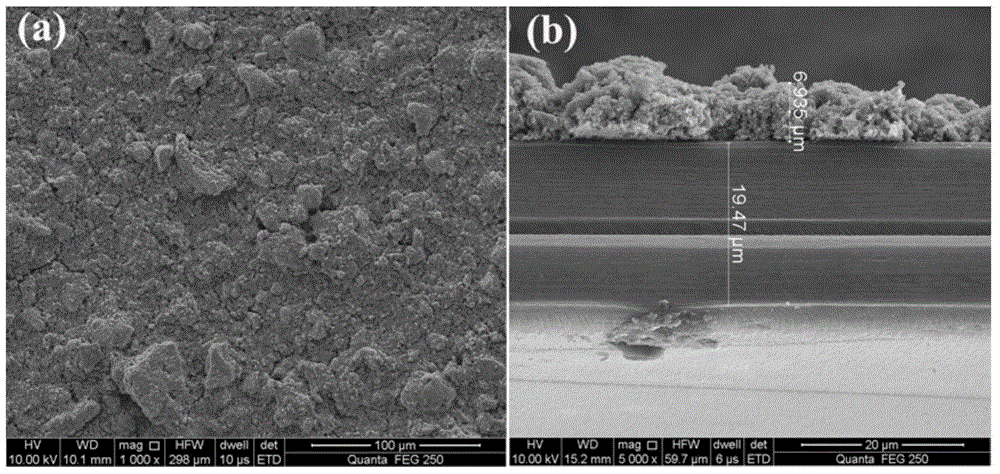

[0036] 2) Preparation of titanium dioxide / porous carbon composite material:

[0037] The precursor titanium-based metal-organic framework prepared in step (1) was...

Embodiment 2

[0045] 1) Preparation of titanium-based metal organic framework:

[0046] Tetrabutyl titanate and 2-aminoterephthalic acid are added in a 1:2 ratio (substance amount ratio) into a mixed solvent with a volume ratio of ethanol and dimethylformamide of 1:9, where the titanium salt is in the organic solvent The concentration is 0.1mol L -1 After mixing uniformly, transfer to a polytetrafluoroethylene autoclave, heat up to 150°C and keep it at this temperature for 20h for solvothermal reaction. After the reaction, cool to room temperature at a rate of 1°C / min at a temperature of 8 000r Centrifugal filtration at speed per minute, alternating washing with methanol and deionized water 3 times, drying at 60°C, and transferring to 200°C vacuum drying oven for 36h activation, thereby obtaining titanium-based metal organic framework;

[0047] 2) Preparation of titanium dioxide / porous carbon composite material:

[0048] The precursor titanium-based metal organic framework prepared in step (1) is...

Embodiment 3

[0052] 1) Preparation of titanium-based metal organic framework:

[0053] Tetrabutyl titanate and trimellitic acid are added to N-formylamide solvent in a ratio of 2:3 (substance amount ratio), and the concentration of titanium salt in the organic solvent is 0.15 mol L -1 After mixing uniformly, transfer to a polytetrafluoroethylene autoclave, heat up to 160°C and keep it at this temperature for 18h for solvothermal reaction. After the reaction, cool to room temperature at a rate of 1°C / min at a rate of 10000r / Centrifugal filtration at min speed, alternating washing with methanol and deionized water 3 times, drying at 60°C, and transferring to 200°C vacuum drying oven for 72h activation, thereby obtaining titanium-based metal organic framework;

[0054] 2) Preparation of titanium dioxide / porous carbon composite material:

[0055] The precursor titanium-based metal-organic framework prepared in step (1) is moved to a tube furnace, and heated from room temperature to 600°C at a heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com