Novel water-supply composite water treatment agent

A water treatment agent and water supply technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of reducing equipment service life, corrosion, bacterial conjunctiva, etc. Achieve the effect of accelerating flocculation speed, stable corrosion inhibition performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

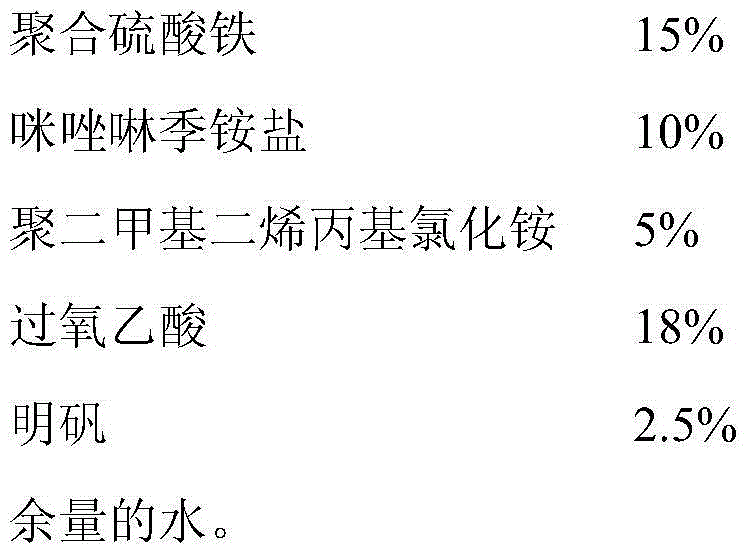

Embodiment 1

[0016] A kind of preparation method of novel water supply composite water treatment agent is as follows:

[0017]

[0018] The production technology of this novel water supply composite water treatment agent is characterized in that it is carried out successively according to the following steps:

[0019] (1) Put polymeric ferric sulfate, imidazoline quaternary ammonium salt, polydimethyldiallyl ammonium chloride, peracetic acid, and alum into the reactor in sequence, fill the reactor with nitrogen, and start stirring;

[0020] (2) Raise the temperature to 80-120°C, stir evenly until all raw materials are completely dissolved, and a new type of water supply composite water treatment agent can be obtained.

[0021] A new type of composite water treatment agent for water supply produced by compounding the raw materials of the present invention, combined with calcium ions and magnesium ions, can not only accelerate the flocculation speed, separate oil droplets and suspended so...

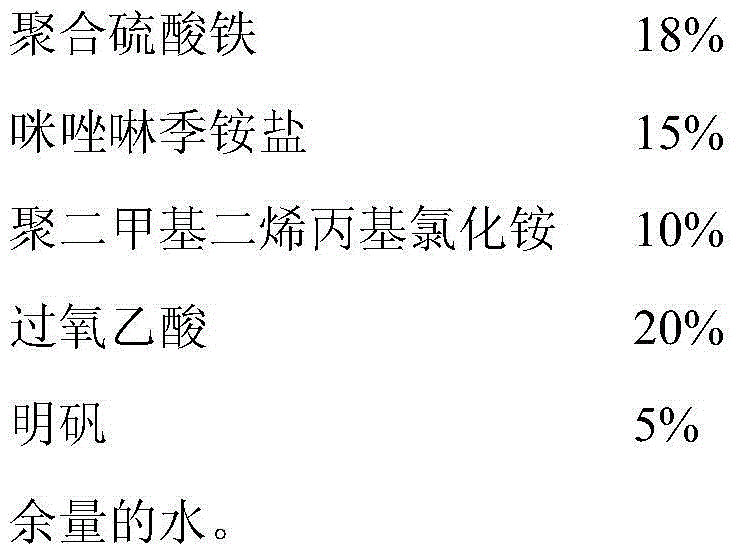

Embodiment 2

[0023] A kind of preparation method of novel water supply composite water treatment agent is as follows:

[0024]

[0025] The preparation steps are the same as in Example 1.

[0026] The invention can remove hydrogen sulfide and carbon dioxide in water without corroding pipelines and pumps of the treatment system, and furthermore, scaling and bacterial conjunctiva will not occur in the treatment process.

Embodiment 3

[0028] A kind of preparation method of novel water supply composite water treatment agent is as follows:

[0029]

[0030] The preparation steps are the same as in Example 1.

[0031] The imidazoline quaternary ammonium salt used in the invention has more stable corrosion inhibition performance, is non-toxic, has no flash point, and is safe and convenient to use and operate.

[0032] When the dosage of this product is 8mg / L, the effluent turbidity of 110-120NTU can be reduced to 5NTU, which is in line with the residual turbidity standard of sedimentation effluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com