Method for preparing silicon-carbon compound from silicon-containing biomass as raw material as well as prepared silicon-carbon compound and application thereof

A carbon composite and biomass technology, applied in the comprehensive field of biological waste resources, can solve problems such as pollution, poor uniformity of silicon-carbon composite materials, poor electrical conductivity, etc., and achieve simple and easy process, rich and cheap raw materials, and uniform particle size distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) 5g of rice husk is acid boiled to remove inorganic salt ion impurities, and then dried after repeated cleaning;

[0024] (2) Grind the rice husk boiled with acid in (1) into powder and carbonize it at 600° C. for 6 hours in an inert atmosphere to obtain a black composite of silicon dioxide and carbon (the mass of silicon dioxide is 0.9 g);

[0025] (3) Add magnesium powder and NaCl to the black product in (2) according to the ratio of silicon dioxide: magnesium powder: NaCl molar ratio 1: 2.5: 10 and ball mill and mix evenly, then put the mixture into a tube furnace to Heating at a heating rate of 5°C / min to 650°C for 3 hours, and taking out the product after cooling to room temperature with the furnace;

[0026] (4) Wash the obtained product in 0.1 mol / L hydrochloric acid and stir for 12 h, then wash and stir in 0.1 mol / L hydrofluoric acid for 12 h, filter with suction and dry to obtain a silicon-carbon composite.

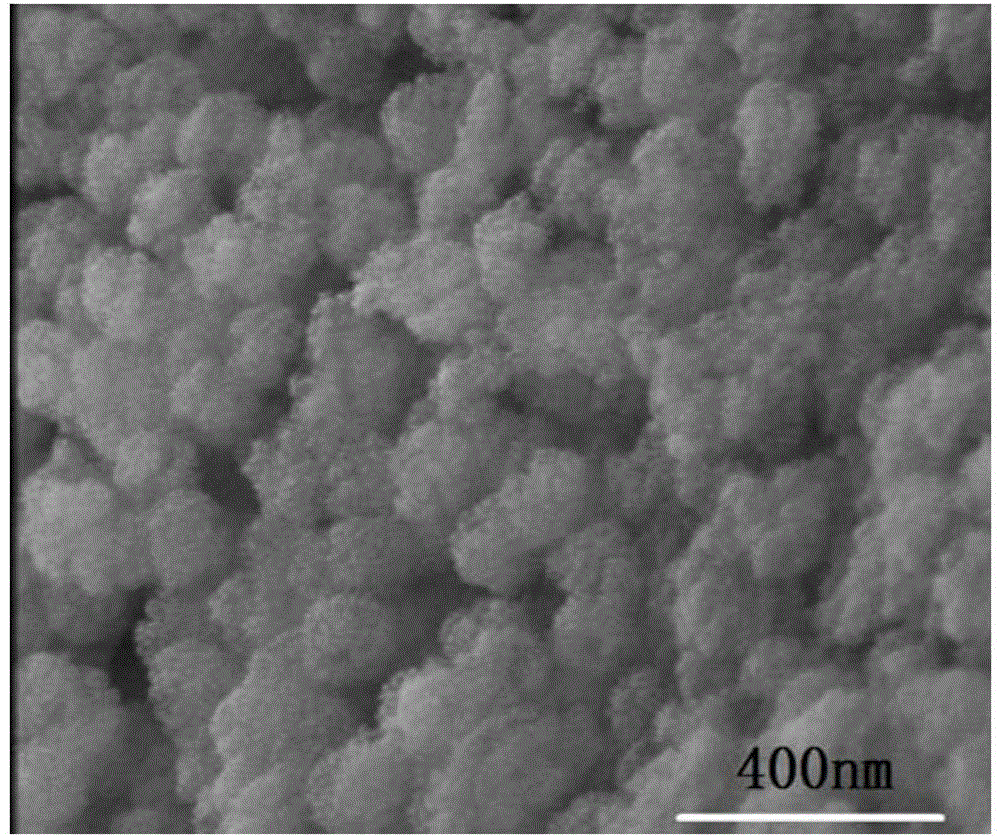

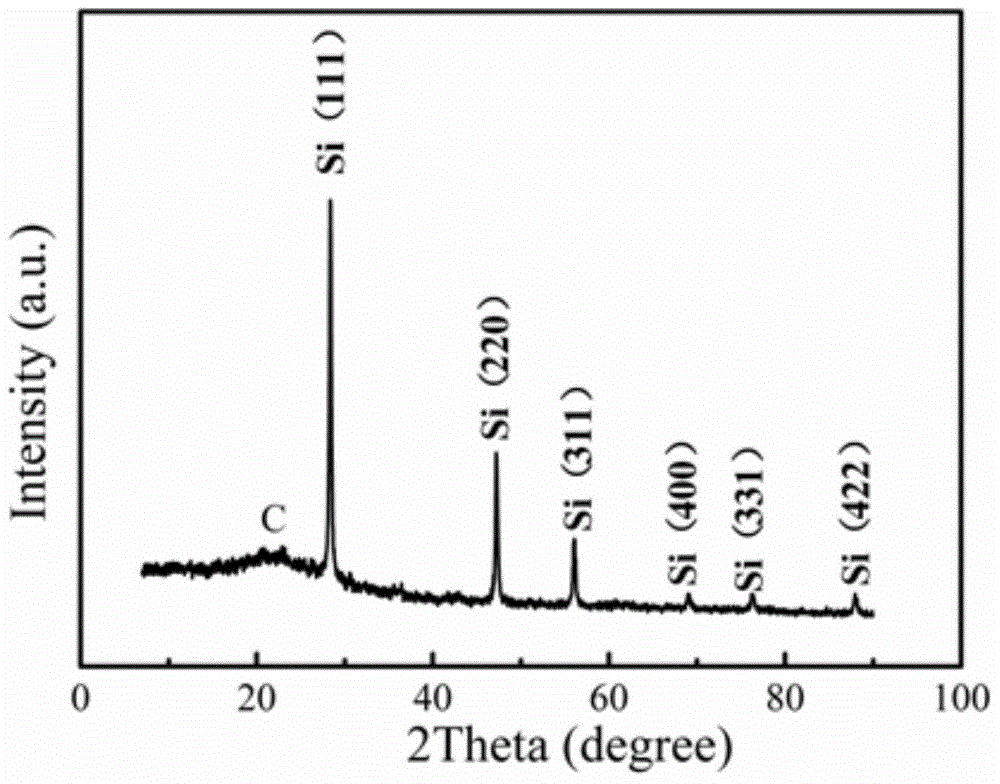

[0027] Depend on figure 1 It can be seen from t...

Embodiment 2

[0029] (1) 5g of bamboo leaf acid is boiled to remove inorganic salt ion impurities, and then dried after repeated cleaning;

[0030] (2) Grind the bamboo leaves boiled with acid in (1) into powder and carbonize them at 400° C. for 12 hours in an inert atmosphere to obtain a black composite of silicon dioxide and carbon (the mass of silicon dioxide is 2.21 g);

[0031] (3) Add magnesium powder and NaCl to the black product in (2) according to the ratio of silicon dioxide: magnesium powder: NaCl molar ratio 1: 1.5: 5 and ball mill to mix evenly, then put the mixture into a tube furnace to Heating at a heating rate of 1°C / min to 600°C for 12 hours, and taking out the product after cooling to room temperature with the furnace;

[0032] (4) Wash the obtained product in 1 mol / L sulfuric acid and stir for 9 h, then wash and stir in 1 mol / L hydrofluoric acid for 9 h, filter with suction and dry to obtain a silicon-carbon composite.

[0033] The silicon-carbon composite is used as th...

Embodiment 3

[0035] (1) 5g of stalks are acid boiled to remove inorganic salt ion impurities, and then dried after repeated washing;

[0036] (2) Grind the straw cooked with acid in (1) into powder and carbonize it at 500°C for 9 hours in an inert atmosphere to obtain a black composite of silicon dioxide and carbon (the mass of silicon dioxide is 0.47g);

[0037] (3) Add magnesium powder and KCl to the black product in (2) according to the ratio of silicon dioxide: magnesium powder: KCl molar ratio 1:0.5:3 and ball milling to mix evenly, then put the mixture into a tube furnace to Heating at a heating rate of 10°C / min to 500°C for 9 hours, and taking out the product after cooling to room temperature with the furnace;

[0038] (4) The obtained product was washed and stirred in 3 mol / L nitric acid and stirred for 6 h, then washed and stirred in 3 mol / L hydrofluoric acid for 6 h, filtered and dried to obtain a silicon-carbon composite.

[0039] The silicon-carbon composite is used as the neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com