Functional polymer thin film, preparation method and application thereof

A functional polymer and polymer technology, which is used in the testing of pharmaceutical preparations, material inspection products, and biological testing. Application prospects, fixation and detection signal enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

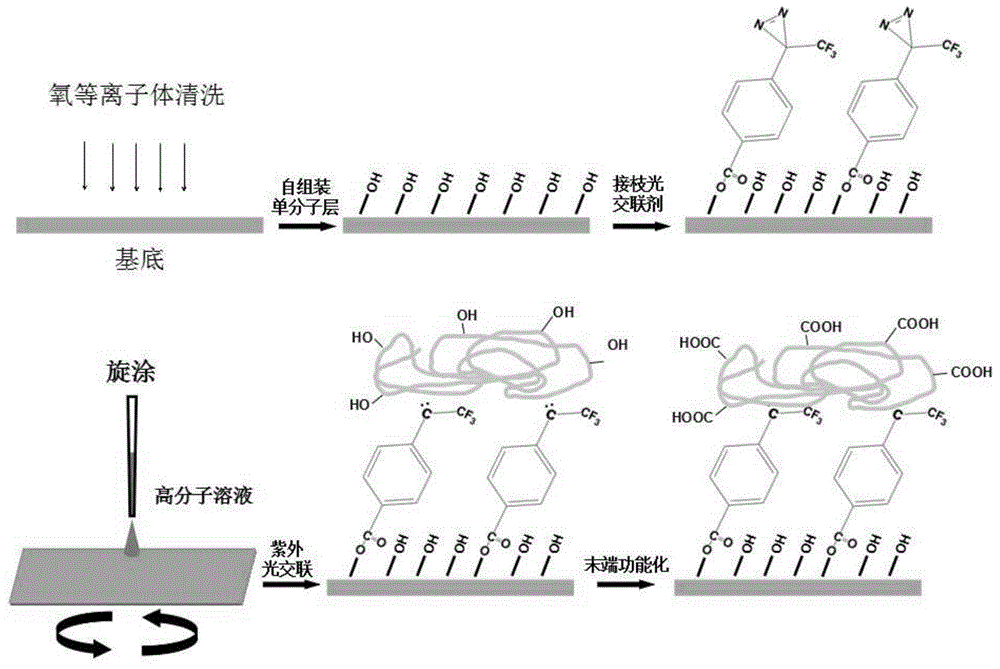

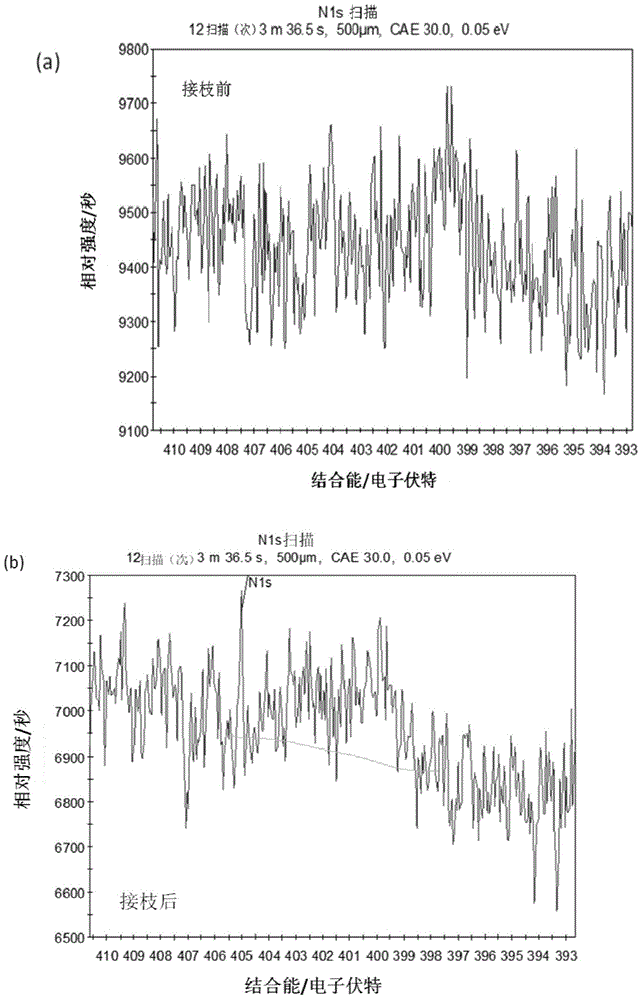

Method used

Image

Examples

Embodiment 1

[0048] Example 1. Dextran surface (small molecule detection: flow-through immobilized SA, detection of Biotin)

[0049] (1) Prepare a layer of chromium layer with a thickness of 3nm and a layer of gold with a thickness of 47nm on the glass substrate by thermal evaporation method, as the substrate of the biochip.

[0050] (2) Prepare the ethanol solution HS-(CH 2 ) 11 -EG6-OH at a concentration of 1 mM.

[0051] (3) The substrate of the biochip is cleaned with ethanol or deionized water, and then the biochip is placed in a plasma cleaner for cleaning for 3 minutes.

[0052] (4) Soak the biochip in the prepared thiol solution and incubate at 4°C for 12 hours. After the predetermined time, the biochip is taken out, washed with ethanol and deionized water alternately, and dried with nitrogen.

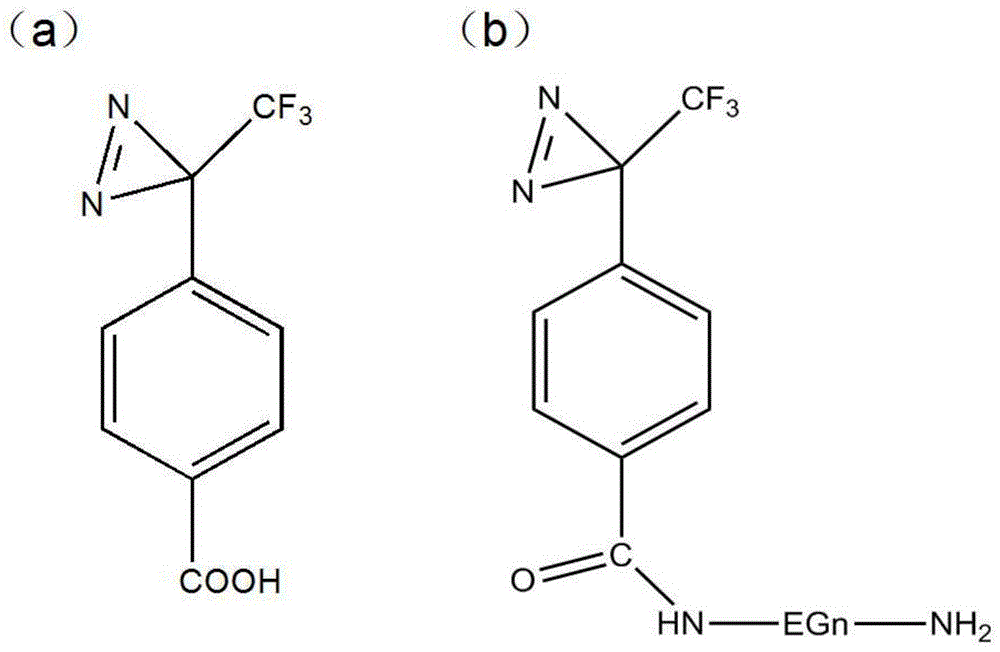

[0053] (5) Prepare 20 mL of the solution required for esterification and linking photocrosslinking agent, 10 mM carboxy-terminal photocrosslinking agent, 1-(3-dimethylaminopropyl)-3-ethy...

Embodiment 2

[0065] Example 2. Poly(polyethylene glycol methacrylate) surfaces (small molecule arrays)

[0066] (1) Prepare a layer of chromium layer with a thickness of 3nm and a layer of gold with a thickness of 47nm on the glass substrate by thermal evaporation method, as the substrate of the biochip.

[0067] (2) Preparation of ethanol solution of hydroxyl-terminated and carboxyl-terminated thiols (HS-(CH 2 ) 11 -EG6-OH and HS-(CH 2 ) 11 -EG6-COOH), the concentration is 1mM, the above two thiol solutions are mixed according to 999:1 (v / v), set aside.

[0068] (3) Clean the biochip with ethanol or deionized water, and then put the biochip into a plasma cleaner for cleaning for 3 minutes.

[0069] (4) Soak the biochip in the mixed thiol solution and incubate at 4°C for 12 hours. After the predetermined time, the biochip is taken out, washed with ethanol and deionized water alternately, and dried with nitrogen.

[0070] (5) Activate the carboxyl groups on the surface of the biochip, ...

Embodiment 3

[0087] Embodiment 3. Dextran surface (antigen antibody fluorescent detection)

[0088] (1) The glass substrate is cleaned with ethanol or deionized water, and the biochip is cleaned in a plasma cleaner for 3 minutes to be used as the substrate of the biochip.

[0089] (2) Prepare 3-aminopropyltriethoxysilane (APES) diluted with acetone at 1:50, take it out after 20-30s, and then use pure acetone solution to remove unbound APES, so that APES can be combined with glass, A monolayer is formed on the surface.

[0090] (3) Soak in 25% glutaraldehyde for 30 minutes, wash with acetone, immerse in 1 mM aqueous solution of PEG with one end being an amino group and one end being a hydroxyl group, and incubate at room temperature for 1 h. After the predetermined time is reached, the biochip is taken out and used Rinse with deionized water and dry with nitrogen gas.

[0091] (4) Prepare 20 mL of the solution required for esterification and linking photocrosslinking agent, 10 mM carboxy-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com