Immersion flow field sealing method based on hydrophilic-hydrophobic alternate surface

A hydrophilic-hydrophobic, flow field technology, applied in the field of immersion flow field sealing based on alternating hydrophilic and hydrophobic surfaces, can solve the problems of increased liquid bubble entrainment, high energy consumption, unfavorable liquid sealing, etc. Scanning speed, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

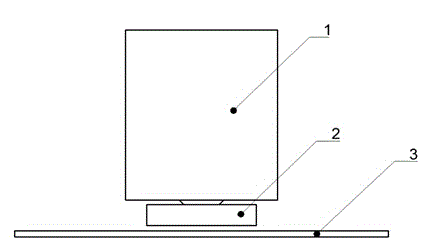

[0026] Such as figure 1 As shown, it shows the assembly of the immersion unit and the projection lens group involved in the embodiment of the invention, and the invention can be used in step-and-repeat or step-and-scan lithography equipment. During the exposure process, light from a light source (not shown in the figure) (such as: ArF or KrF excimer laser) passes through the aligned mask plate (not shown in the figure), projection lens group 1 and filled with immersion liquid The gap flow field between the lens and the substrate exposes the photoresist on the surface of the substrate 3 .

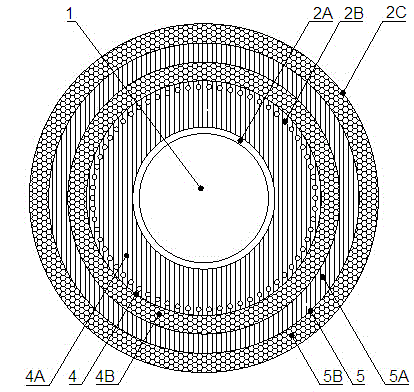

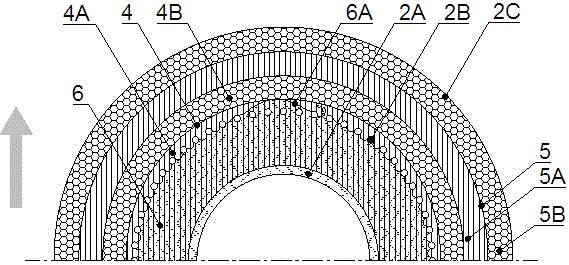

[0027] Such as figure 1 , figure 2 As shown, the method for sealing the lower surface of the immersion unit 2 between the projection lens group 1 and the silicon wafer substrate 3 to be exposed in the immersion lithography system includes a first-level hydrophilic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com