Silicon chip surface defect detector capable of classifying defects and defect classifying method

A technology for defect classification and silicon wafer surface, which is applied in the direction of optical defect/defect, instrument, scattering characteristic measurement, etc. It can solve the problems of defect detection function, unable to analyze the spatial distribution of scattered light, and unable to classify defects, etc., to reduce the focus spot , Measuring the effect of signal-to-noise ratio enhancement and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

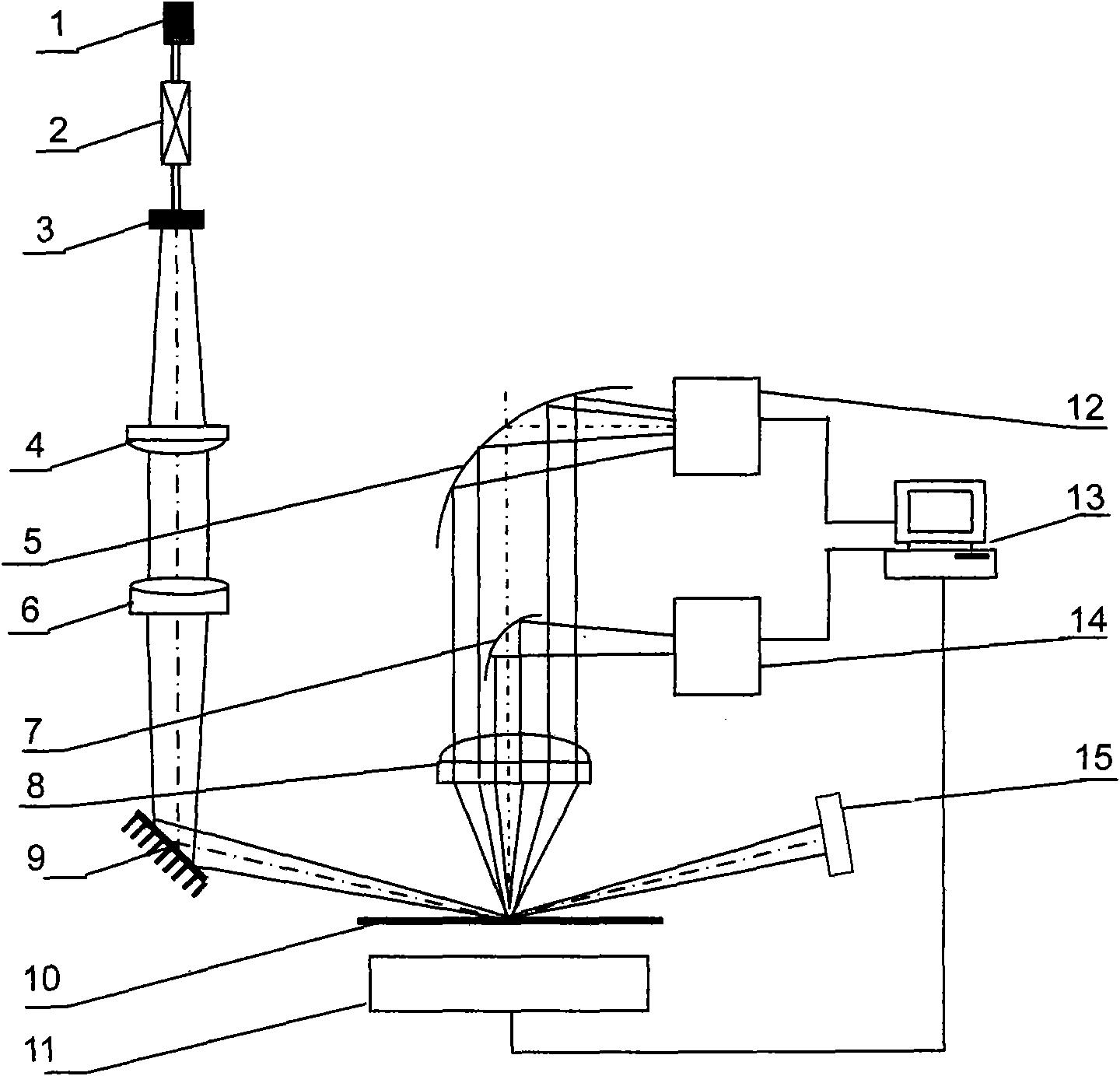

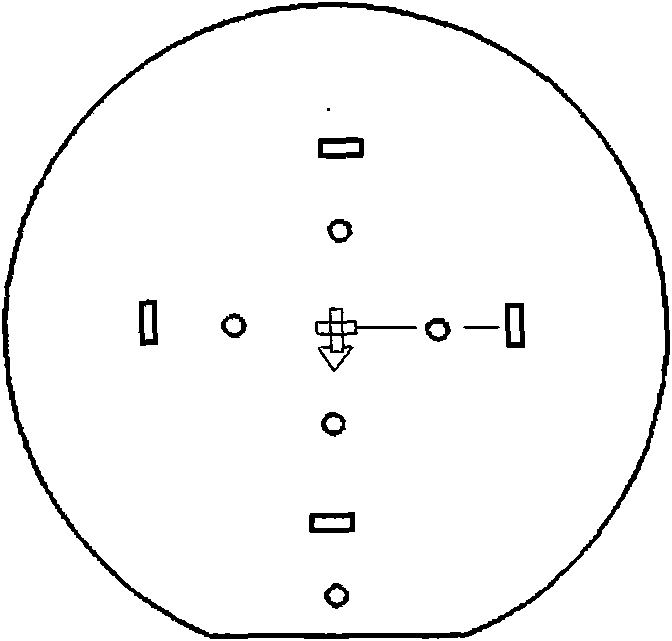

[0031] see first figure 1 . figure 1 It is a schematic diagram of the principle of the silicon wafer surface defect detection system with defect classification capability of the present invention, and is also a structural schematic diagram of the best embodiment of the present invention. It can be seen from the figure that the silicon wafer surface defect detector with defect classification capability of the present invention comprises: in the direction of the light beam emitted by the laser light source assembly 1, there are sequentially an isolator 2, a biconcave lens 3 and a first plano-convex lens 4 Composed of a beam expander system, a double cemented focusing lens 6 and a plane mirror 9; the silicon wafer 10 to be measured is located on a silicon wafer workbench 11 capable of simultaneous rotation and off-axis translation; the light beam is turned by the plane mirror 9 Oblique focusing is incident on the surface of the silicon wafer 10 to be measured, and an optical t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com