Preparation method of strong ultraviolet photoluminescent ZnO ordered nano column

A technology of nano-columns and ultraviolet light, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of obvious luminescence, reduced luminescence of red light defects, and low luminous efficiency of purple light, so as to achieve obvious enhancement effect, increase radiation recombination rate, The preparation method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

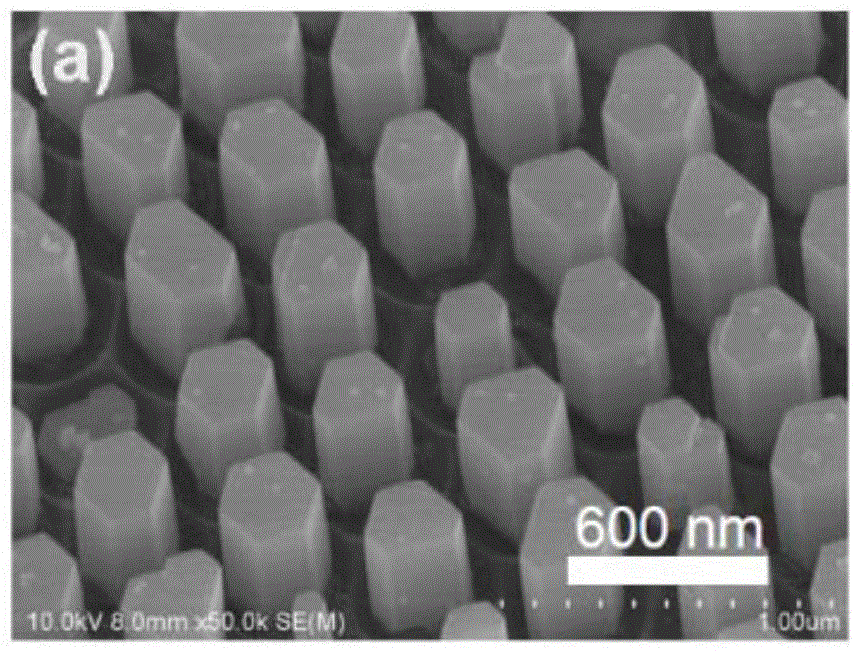

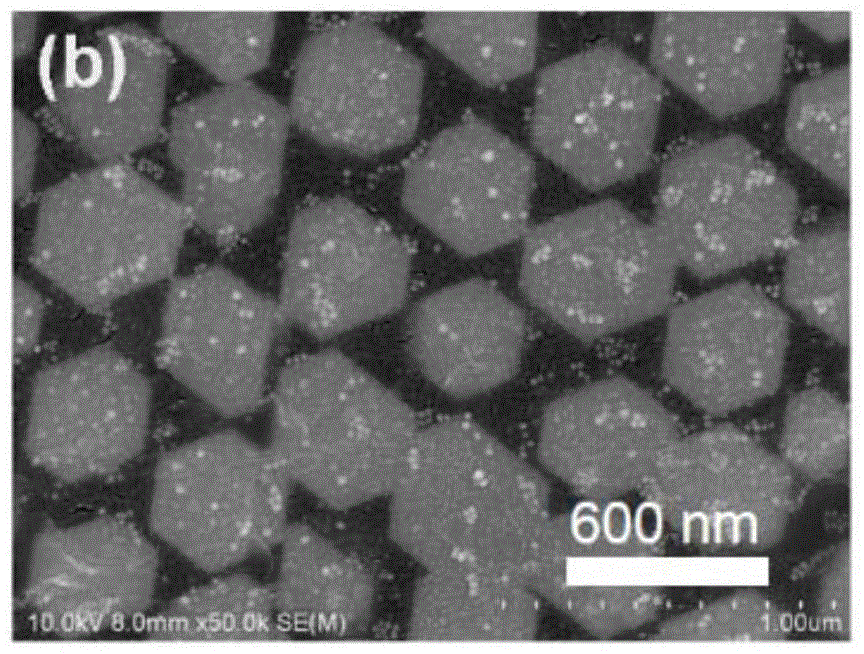

[0033] Such as figure 1 As shown, the preparation method of the strong ultraviolet photoluminescence ZnO ordered nanocolumn of the present embodiment comprises the following steps:

[0034] (1) Preparation of ZnO ordered nanocolumns:

[0035] (1-1) Assemble single-layer polystyrene microspheres on Si substrates by pulling method: put the silicon substrate into H 2 SO 4 :H 2 o 2 (volume ratio)=3:1 solution soaks 3 hours and carries out hydrophilic treatment to substrate;

[0036] Fix the two silicon wafers after hydrophilic treatment on the sample table and the lifting rod of the pulling machine respectively, fix the two silicon wafers in parallel, adjust the distance between them at 140 μm, and use a pipette gun to place the gap between the two silicon substrates. Drop 1-2 drops of polystyrene microsphere solution into the glass, let it stand for about 3 minutes, and then lift the silicon wafer on the lifting rod at a constant speed. Finally realize the self-assembled si...

Embodiment 2

[0046] The preparation method of the strong ultraviolet photoluminescence ZnO ordered nanocolumn of the present embodiment comprises the following steps:

[0047] (1) Preparation of ZnO ordered nanocolumns:

[0048] (1-1) on SiO 2 Or assemble single-layer polystyrene microspheres on Si substrate by pulling method, the pulling rate is 300μm / s;

[0049] (1-2) Transfer monolayer polystyrene microspheres to GaN substrate, and spin-coat TiO in the substrate gap 2 colloid;

[0050] (1-3) Ultrasonically remove polystyrene microspheres in toluene to expose the GaN surface on which ordered ZnO nanocolumns need to grow, the ultrasonic power is 5W, and the ultrasonic time is 20min;

[0051] (1-4) Adopting hydrothermal reaction method to grow ZnO ordered nanocolumns: the reaction vessel is a high-pressure reactor, and the reactant is a mixed solution of zinc nitrate hexahydrate and hexamethyltetramine, and the concentration of the reactant is 0.03mol / L , the reaction temperature is 40...

Embodiment 3

[0056] The preparation method of the strong ultraviolet photoluminescence ZnO ordered nanocolumn of the present embodiment comprises the following steps:

[0057] (1) Preparation of ZnO ordered nanocolumns:

[0058] (1-1) on SiO 2 Or assemble single-layer polystyrene microspheres on Si substrate by pulling method, and the pulling rate is 600 μm / s;

[0059] (1-2) Transfer monolayer polystyrene microspheres to GaN substrate, and spin-coat TiO in the substrate gap 2 colloid;

[0060] (1-3) Ultrasonically remove polystyrene microspheres in toluene to expose the GaN surface on which ordered ZnO nanocolumns need to grow, the ultrasonic power is 5W, and the ultrasonic time is 40min;

[0061] (1-4) Adopting hydrothermal reaction method to grow ZnO ordered nanocolumns: the reaction vessel is a high-pressure reactor, the reactant is a mixed solution of zinc nitrate hexahydrate and hexamethyltetramine, and the concentration of the reactant is 0.07mol / L , the reaction temperature is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com