Epoxy die-bonding adhesive and preparation method thereof and multi-chip embedded flexible printed circuit board

A technology of epoxy solidification and solid crystal glue, which is applied to the printed circuit, epoxy resin glue, adhesive and other directions connected with non-printed electrical components, which can solve the problems of high curing temperature, low bonding strength and slow speed. , to achieve the effect of improving mechanical properties, ensuring reliability, and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

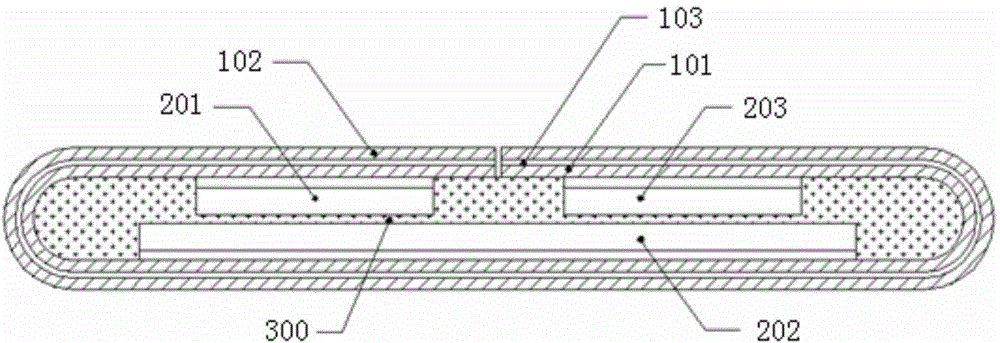

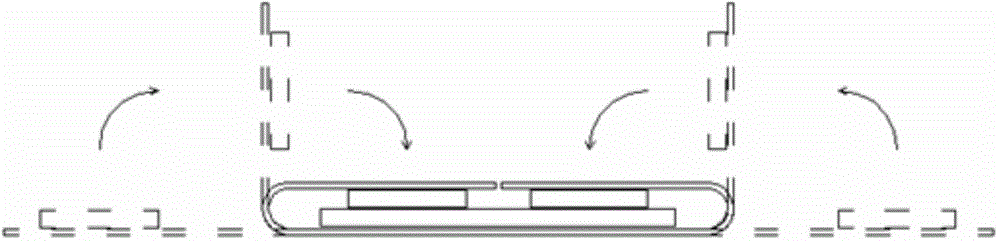

Image

Examples

preparation example Construction

[0041] A preparation method of low modulus, high thixotropic epoxy crystal-bonding adhesive, comprising epoxy resin, curing agent, curing accelerator, toughening agent, thixotropic agent, diluent, red pigment and stabilizer, through stirring and mixing Made evenly.

[0042] The epoxy resin is a low-viscosity epoxy resin, such as: E-51 or E-55 epoxy resin, bisphenol F epoxy resin, etc. This type of resin has low viscosity and good fluidity, and is suitable for high-speed dispensing process , and also has the characteristics of good heat resistance and excellent electrical properties;

[0043] The curing agent is an imidazole derivative containing a long-chain substituted alkyl group, such as: 2-undecylimidazole, 2-nonylimidazole, etc., which is a type of latent curing agent, which is beneficial to improve the pot life of the glue. At the same time, the long alkyl chain also helps to improve the flexibility of epoxy cured products;

[0044]The curing accelerator is a latent cu...

Embodiment 1

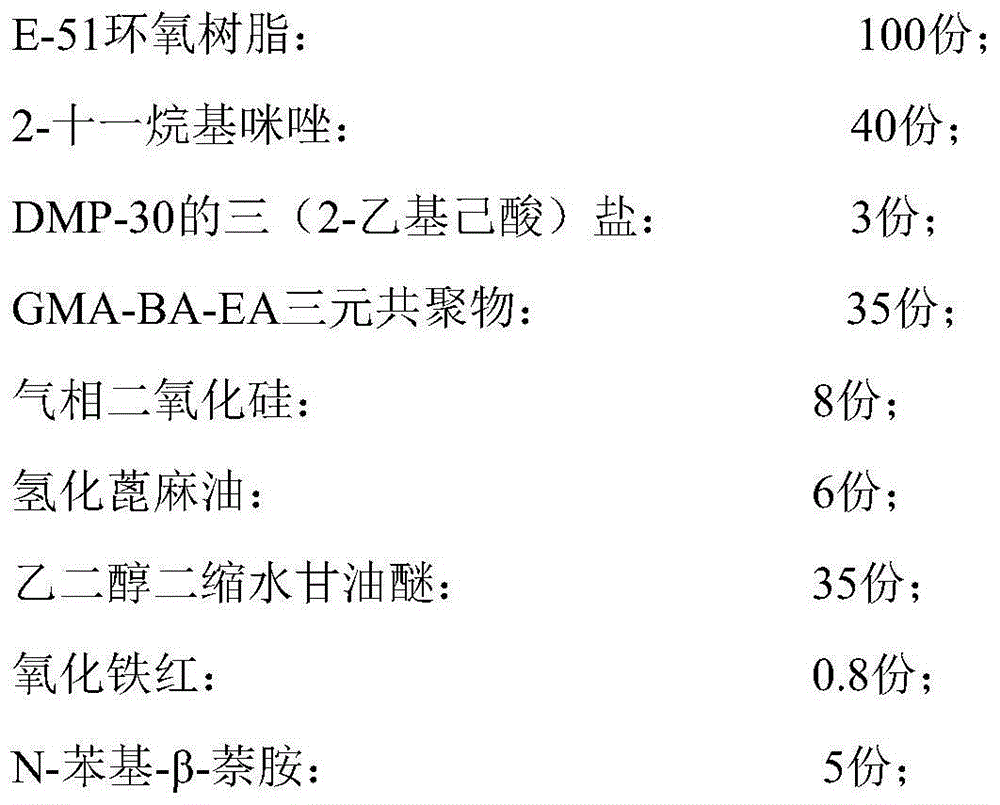

[0055] The formula of epoxy crystal-bonding adhesive is as follows (parts by weight):

[0056]

[0057] The preparation steps are as follows:

[0058] S1: Mix 40g of 2-undecylimidazole and 5g of N-phenyl-β-naphthylamine with 50g of E-51 epoxy resin in a planetary dynamic mixer to form a paste, and grind it through a three-roller machine 2 times, spare;

[0059] S2: Add the remaining 50g of E-51 epoxy resin, 35g of ethylene glycol diglycidyl ether, 35g of GMA-BA-EA terpolymer, 6g of hydrogenated castor oil in the planetary power mixer, control material Temperature 80-85°C, stir until the hydrogenated castor oil is completely dissolved, then pass cooling water to the jacket of the stirred tank to reduce the temperature of the material to below 35°C;

[0060] S3: Add the latent curing agent paste in S1, 8g of fumed silica, 0.8g of red iron oxide, and 3g of DMP-30 tris(2-ethylhexanoate) salt to the mixture in S2, and stir After uniformity, turn on the vacuum system and conti...

Embodiment 2

[0065] The formula is as follows:

[0066]

[0067] The preparation steps are similar to Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com