Preparation method of POSS (polyhedral oligomeric silsesquioxane)-based porous material capable of simultaneously improving porosity and carbon dioxide storage volume

A carbon dioxide and porous material technology, applied in the field of preparation of POSS-based porous materials, can solve problems such as the reduction of porous properties, and achieve the effects of increased pore volume and carbon dioxide storage capacity, excellent porous properties and carbon dioxide storage properties, and simple preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation of the POSS-based porous material (HPP-1-EDA) of embodiment 1, ethylenediamine functionalization

[0061] The POSS-based porous material described in this embodiment is a POSS-based porous material (HPP-1 ), the reaction formula is as follows:

[0062]

[0063] The preparation steps are as follows:

[0064] In a 100 mL dry round bottom flask, were added octavinyl POSS (632 mg, 1 mmol), 2,7-dibromo-9-fluorenone (1.35 g, 4 mmol), palladium acetate (90 mg, 0.4 mmol) and tris(o Methylphenyl) phosphorus (126mg, 0.48mmol), then add 45mL N,N-dimethylformamide and 15mL triethylamine, after stirring at room temperature, bubble with argon for at least half an hour, slowly raise the temperature to 100 °C, stirred at 100 °C for 48h.

[0065] After the reaction is completed and the reaction system returns to room temperature, the solid is filtered with suction, and the filter cake is washed with water, tetrahydrofuran, chloroform, water, methanol and acetone in...

Embodiment 2

[0076] The preparation of the POSS-based porous material (HPP-1-DAH) of embodiment 2, hexamethylenediamine functionalization

[0077] In a 100mL round-bottomed flask, add 0.3g of the POSS-based porous material HPP-1 prepared in Example 1 and 6g of hexamethylenediamine, then add 50mL of tetrahydrofuran and 5 drops of formic acid, reflux for 36h, filter with suction, and wash the filter cake three times with tetrahydrofuran. 50 mL was used each time, and then the filter cake was vacuum-dried at 80° C. for 18 h. Finally, 0.32 g of brown solid HPP-1-DAH was obtained.

[0078] The reaction formula is as follows:

[0079]

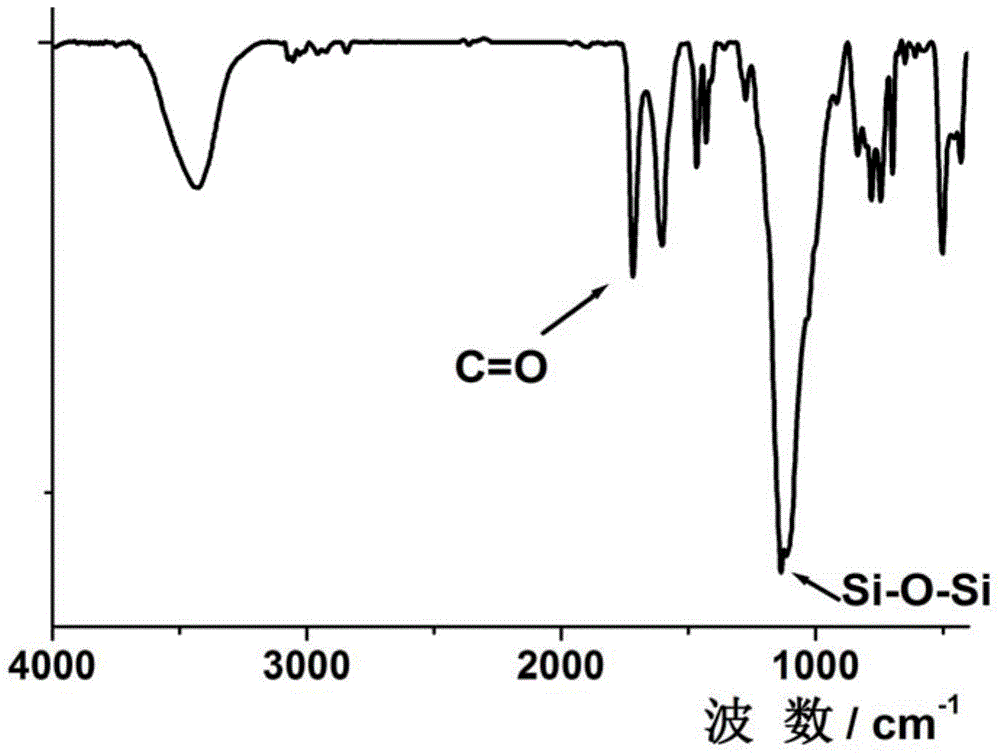

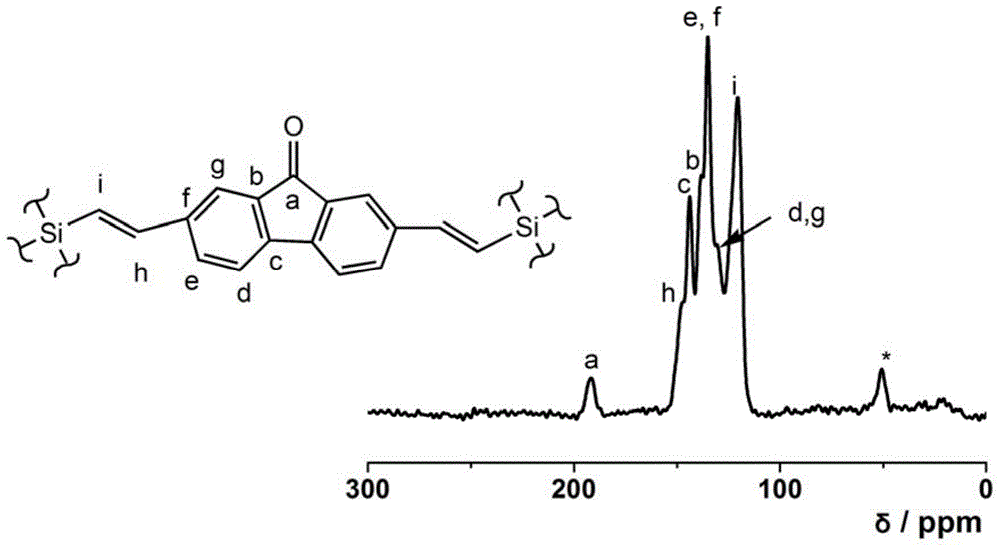

[0080] The infrared spectrum of HPP-1-DAH is attached Figure 9 , compared with HPP-1, 1718cm -1 The stretching vibration of the carbon-oxygen double bond of the carbonyl group in fluorenone is significantly weakened, and the peaks at other positions do not change significantly. Its solid NMR carbon spectrum is shown in the appendix Figure 10 , compared ...

Embodiment 3

[0083] The preparation of the POSS-based porous material (HPP-2-EDA) of embodiment 3, ethylenediamine functionalization

[0084] The POSS-based porous material described in this embodiment is composed of eight iodine (bromo) phenyl POSS (POSS-Ph-X-1) and FO-B (OH) 2 (HPP-2) was prepared by Suzuki reaction; the reaction formula is as follows:

[0085]

[0086] The preparation steps are as follows:

[0087] In a dry 100 mL round bottom flask, POSS-Ph-X-1 (X=I: 1.22 g, 0.6 mmol; X=Br: 998 mg, 0.6 mmol) and 2,7-diboronic acid-9-fluorenone ( 604mg, 2.4mmol) was added to 10mL N,N-dimethylformamide, then tetrakis(triphenylphosphine)palladium (277mg, 0.24mmol) and potassium carbonate aqueous solution (2.0M, 0.20mL) were added, and stirred at room temperature After that, bubble with argon for at least 0.5h, slowly raise the temperature to 120°C, and stir at 120°C for 48h.

[0088] After the reaction was completed and the reaction system returned to room temperature, the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com