Fischer-Tropsch synthesis reaction waste water resource treatment process and its system

A Fischer-Tropsch synthesis and treatment technology, applied in water/sewage treatment, anaerobic digestion treatment, natural water treatment, etc., can solve the problems of inability to discharge directly, increase the consumption of desalinated water, and high cost, and reduce the difficulty of recovery and cost, improved water resources, and the effect of reducing the amount of wastewater discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

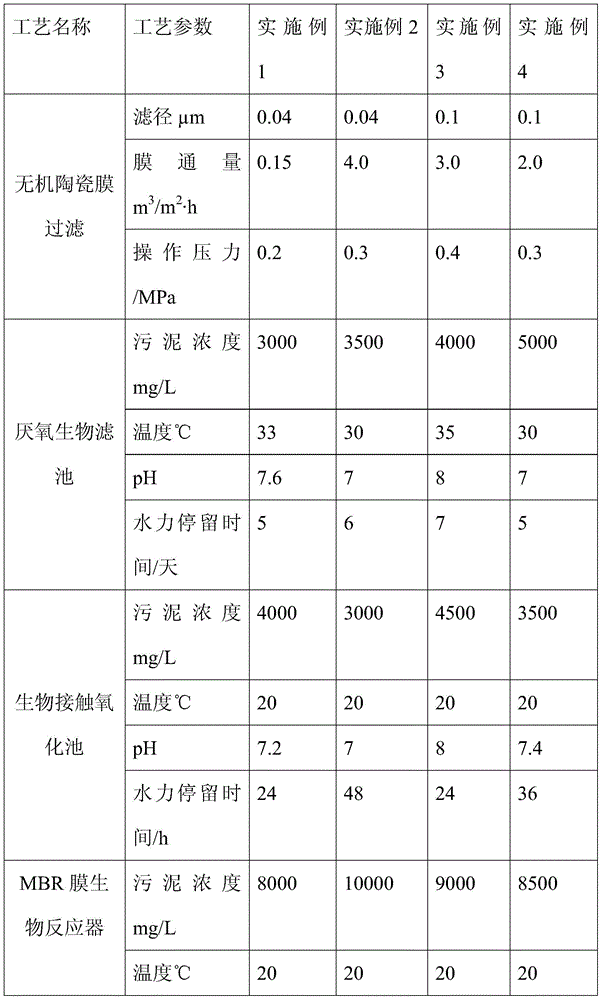

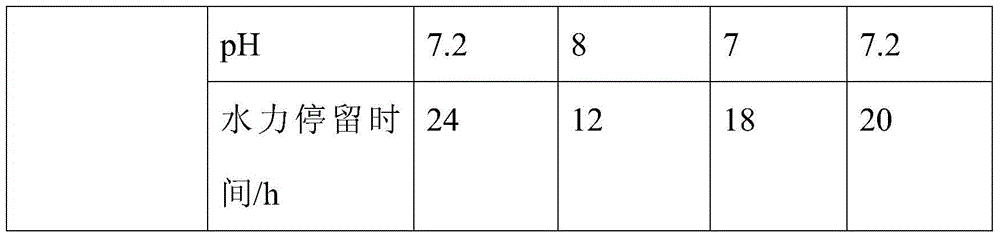

Embodiment 1~4

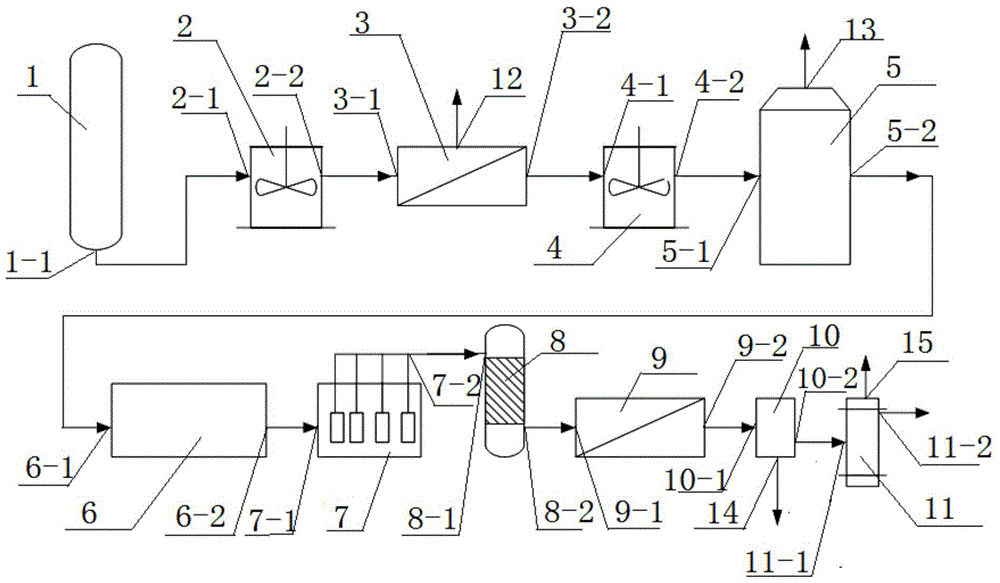

[0032] A Fischer-Tropsch synthesis reaction waste water resource treatment process is as follows:

[0033] 1) Filtration treatment: Take 200L Fischer-Tropsch synthesis reaction wastewater from the wastewater outlet 1-1 of the Fischer-Tropsch synthesis reactor 1 and put it into the mixing tank 2. The CODcr of the wastewater is 45760mg / L. The step speed mixing mixer stirs the wastewater for 30 minutes, mixes evenly, and then uses an acid-resistant pump to transport the wastewater to an inorganic ceramic membrane filter device 3 with a filter diameter of 0.04-0.1 μm for filtration treatment. The inorganic ceramic membrane is a silicon carbide ceramic membrane, and the membrane tube It is an internal pressure type, and its membrane flux is preferably 0.15-4m 3 / m 2 h, the filtration operating pressure is preferably 0.2-0.4MPa. After 4 hours of filtration, the oil-containing concentrated water whose main components are hydrocarbons and macromolecular organic oxygen-containing comp...

Embodiment 5

[0046] The effluent after the secondary aerobic treatment of Example 1 is sequentially passed through the fine filtration device 8, the reverse osmosis membrane device 9, the EDI device 10, and the degassing membrane device 11 for desalination treatment to remove dissolved ionic solids and a small amount of Organic matter, wherein the fine filter device 8 adopts a hollow fiber membrane with a filtration accuracy of 1 μm; the operating conditions of the reverse osmosis membrane device 9 are: water temperature is 15°C, pH is 7.2, operating pressure is 1.2MPa, and the membrane flux of the reverse osmosis membrane is 30L / m 2 h; the operating conditions of the EDI device 10 are: water temperature is 20°C, the pH is 7.2, the operating pressure is 0.35 MPa, and the water hardness is 0.75 mg / L; the operating conditions of the degassing membrane device 11 are: the pH is 7.2, dissolved oxygen in water 2.3mg / L, the operating pressure is 0.25MPa, and the effluent treated by the degassing...

Embodiment 6

[0049] The effluent after the secondary aerobic treatment of Example 2 is sequentially passed through the fine filtration device 8, the reverse osmosis membrane device 9, the EDI device 10, and the degassing membrane device 11 for desalination treatment to remove dissolved ionic solids and a small amount of Organic matter, among which, the fine filter device 8 adopts a hollow fiber membrane with a filtration accuracy of 1 μm; the operating conditions of the reverse osmosis membrane device 9 are: water temperature 20°C, pH 6, operating pressure 1.0MPa, reverse osmosis membrane flux 40L / m 2 h; the operating conditions of the EDI device 10 are: the water temperature is 10°C, the pH is 6, the operating pressure is 0.25 MPa, and the water hardness is 1.0 mg / L; the operating conditions of the degassing membrane device 11 are: the pH is 6, the dissolved oxygen in water 12mg / L, the operating pressure is 0.2MPa, and the effluent treated by the degassing membrane device 11 is reused as b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com