PCD cutter with high performance

A high-performance, cutting tool technology, applied in the direction of cutting tools, milling cutters, drilling tool accessories, etc. used in lathes, can solve the problems of horizontal lines on the workpiece, low surface finish of the workpiece, and insufficient surface brightness of the workpiece, and achieves a high level of improvement. Surface brightness, avoid chipping or cracking, strong oxidizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of high-performance PCD cutter, its manufacture method comprises the following steps:

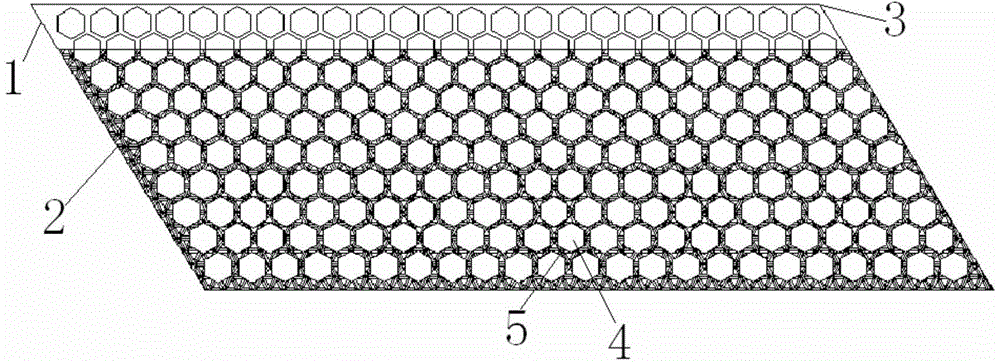

[0029] 1) A PCD cutter is provided, comprising a cutter base and a PCD blade welded on the cutter base, the PCD blade is composed of a blade base and a polycrystalline diamond layer;

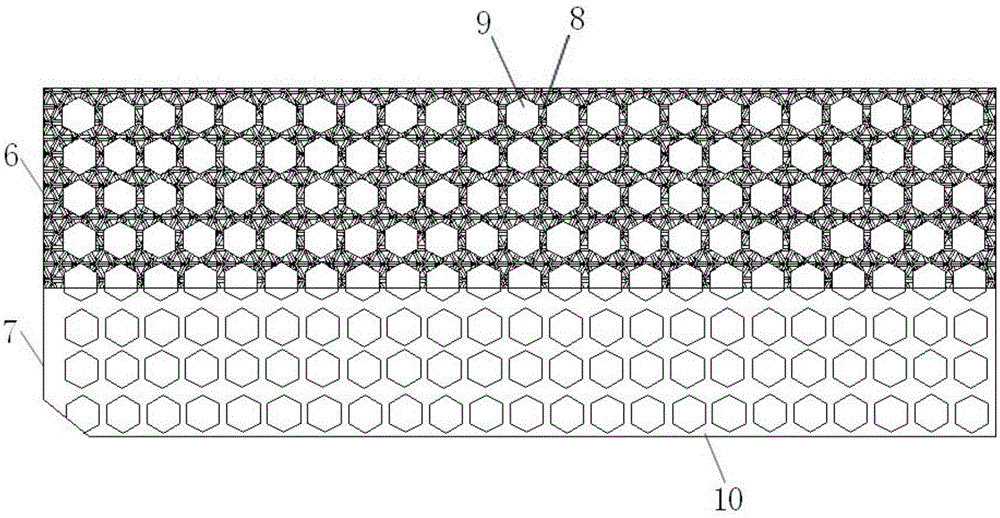

[0030] 2) Spray Teflon on the outer surface of the part of the PCD cutter except the polycrystalline diamond layer to form a protective layer; wherein, the part of the PCD cutter except the polycrystalline diamond layer specifically refers to the cutter substrate and the blade substrate; Before spraying Teflon, the PCD tool should be ultrasonically cleaned with cleaning solution for 10-15 minutes, rinsed with deionized water for 3-5 times, and dried in a vacuum drying oven at 120°C for 1 hour. This process is to ensure that the tool surface is clean and Teflon sprayed evenly when the tool surface is sprayed with Teflon. Since the Teflon coating has stable chemical properties and is insoluble in...

Embodiment 2

[0036] The characteristics of this embodiment are: in step 3), the formula of the cobalt removal solution is: 98% concentrated sulfuric acid 15 at.%, nitric acid 20 at.%, phosphoric acid 10 at.%, hydrogen peroxide 15 at.%, pure water as solvent. Put the PCD tool treated in step 2) into the above-mentioned cobalt-removing solution, set the reaction temperature to 70°C, stir the cobalt-removing solution evenly, and react for 3 hours; then take out the PCD tool and clean it until neutral; finally remove the PCD tool Teflon sprayed on the outer surface, that is.

[0037] After testing, the removal width of the metal cobalt element in the polycrystalline diamond layer on the rake face of the PCD tool is 1-3 mm, and the removal thickness of the metal cobalt element in the polycrystalline diamond layer on the flank face of the PCD tool is 0.05-0.1 mm.

[0038] Others are the same as in Example 1.

Embodiment 3

[0040]The characteristics of this embodiment are: in step 3), the formula of cobalt removal solution is: 98% concentrated sulfuric acid 15 at.%, nitric acid 30 at.%, phosphoric acid 15 at.%, hydrogen peroxide 10 at.%, purified water as solvent. Put the PCD tool treated in step 2) into the above-mentioned cobalt-removing solution, set the reaction temperature to 60°C, stir the cobalt-removing solution evenly, and react for 2 hours; then take out the PCD tool and clean it until neutral; finally remove the PCD tool Teflon sprayed on the outer surface, that is.

[0041] After testing, the removal width of the metal cobalt element in the polycrystalline diamond layer on the rake face of the PCD tool is 1-3 mm, and the removal thickness of the metal cobalt element in the polycrystalline diamond layer on the flank face of the PCD tool is 0.05-0.1 mm.

[0042] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com