Particle composition as well as preparation method and preparation thereof

A technology for compositions and compound preparations, applied in the field of pharmaceutical preparations, to achieve the effects of improving stability, improving incompatibility difficulties, and overcoming incompatibility taboos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

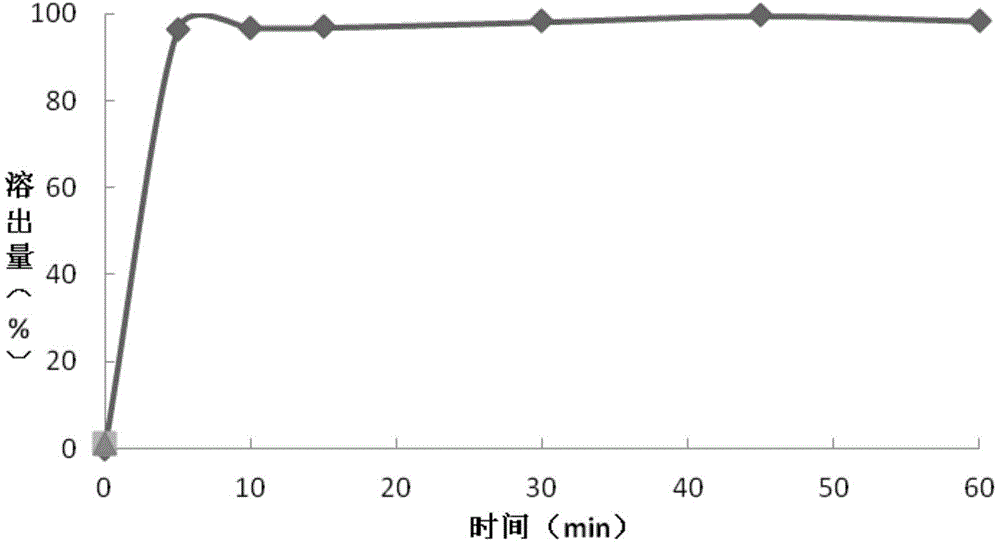

[0075] The preparation of embodiment 1 granular composition

[0076] The formulation of the granular composition is shown in Table 1.

[0077] Table 1 Prescription of Granular Composition

[0078]

[0079] Preparation of Montelukast sodium granules: Add purified water into a stainless steel bucket, add meglumine and stir until dissolved; continue stirring and add hydroxypropyl-β-cyclodextrin until dissolved, and finally add Montelukast sodium and stir until dissolved. Dissolve to obtain the first binder solution and set aside. Put the mannitol in a wet granulator after passing through a 26-mesh sieve, put the prepared first binder solution in a wet-process granulator, and make soft materials, which pass through a 26-mesh sieve for granulation, and dry at 45°C for 15 Minutes later, pass through a 26-mesh sieve for granulation, continue to dry until the loss on drying is ≤2.0% (IR90°C, dry for 10 minutes), pass through a 26-mesh sieve for granulation, and obtain montelukast...

Embodiment 2

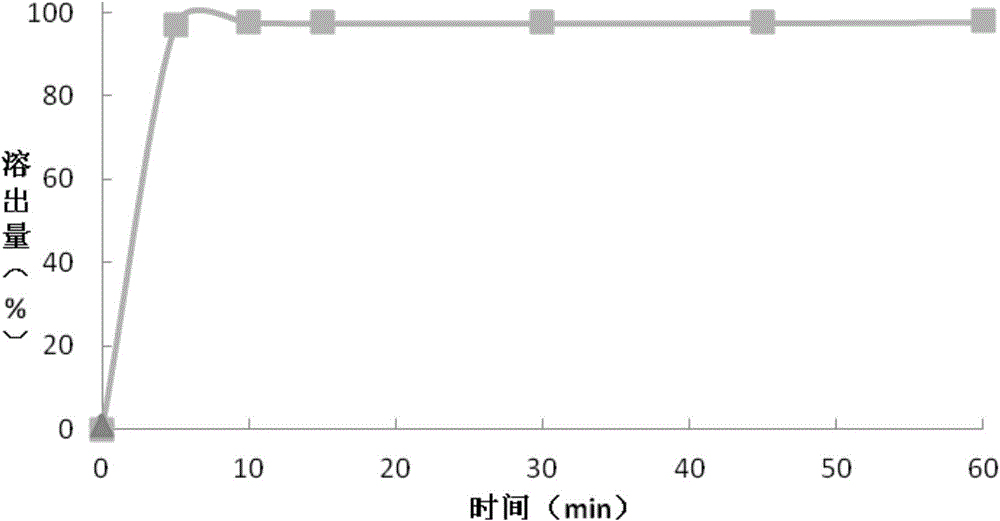

[0082] The preparation of embodiment 2 granular composition

[0083]The formulation of the granular composition is shown in Table 2.

[0084] Table 2 Prescription of Granular Composition

[0085]

[0086] Preparation of Montelukast sodium granules: Add purified water into a stainless steel bucket, add meglumine and stir until dissolved; continue stirring and add hydroxypropyl-β-cyclodextrin until dissolved, and finally add Montelukast sodium and stir until dissolved. Dissolved to obtain the first binder solution, set aside. Mannitol and microcrystalline cellulose 101 were respectively passed through a 26-mesh sieve, mixed evenly and placed in a wet granulator, and the prepared first binder solution was placed in a wet granulator to make soft materials, and the soft materials were passed through Granulate with a 26-mesh sieve, dry at 45°C for 15 minutes, pass through a 26-mesh sieve for granulation, continue to dry until the drying weight loss ≤ 2.0% (IR90°C, dry for 10 mi...

Embodiment 3

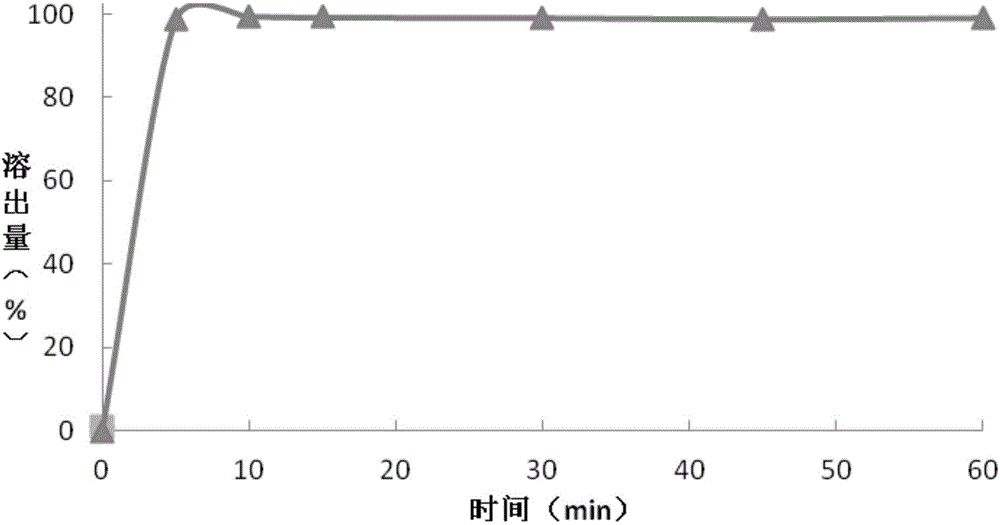

[0089] The preparation of embodiment 3 granular composition

[0090] The formulation of the granular composition is shown in Table 3.

[0091] Table 3 Prescription of Granular Composition

[0092]

[0093]

[0094] Preparation of Montelukast sodium granules: Add purified water into a stainless steel bucket, add meglumine and stir until dissolved; continue stirring and add hydroxypropyl-β-cyclodextrin until dissolved, and finally add Montelukast sodium and stir until dissolved. Dissolved to obtain the first binder solution, set aside. Put the mannitol in a wet granulator after passing through a 26-mesh sieve, put the prepared first binder solution in a wet-process granulator, and make soft materials, which pass through a 26-mesh sieve for granulation, and dry at 45°C for 15 Minutes later, pass through a 26-mesh sieve for granulation, continue to dry until the loss on drying is ≤2.0% (IR90°C, dry for 10 minutes), pass through a 26-mesh sieve for granulation, and obtain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com