Two-way stretchable supercapacitor and manufacturing method thereof

A supercapacitor and electrode technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as bidirectional or multidirectional stretching, difficulty in meeting the needs of wearable applications, etc., and achieve easy Realization, excellent tensile recovery performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] By adopting the invention, a planar bidirectional stretchable supercapacitor is prepared.

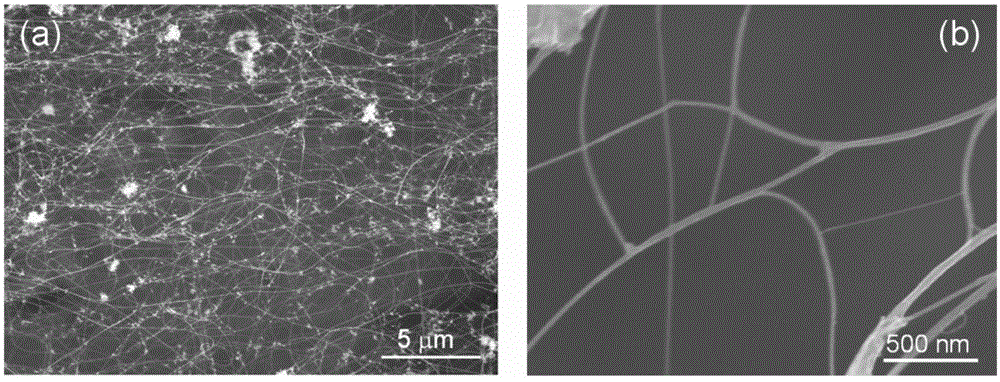

[0057] Firstly, the carbon nanotube film is prepared as the electrode material of the biaxially stretchable supercapacitor by gas-phase flow catalytic reaction method. The carbon nanotube film is 2.0 cm wide and 100 nm thick. The carbon nanotubes in the film are mainly double-walled, and the diameter of the carbon nanotubes is 7nm. Carbon nanotubes combine with each other to form bundles, bifurcate and connect with each other to form a network. The network pore size distribution ranges from 5nm to 5μm. The length of carbon nanotubes and carbon nanotube bundles is more than 1μm, and the aspect ratio is more than 100. Such as image 3 A scanning electron microscope image (S-4800, Hatchi, Japan) of the carbon nanotube network is shown. The carbon nanotube membrane is defined as the membrane length along the spinning direction, and defined as the membrane width perpendicular to th...

Embodiment 2

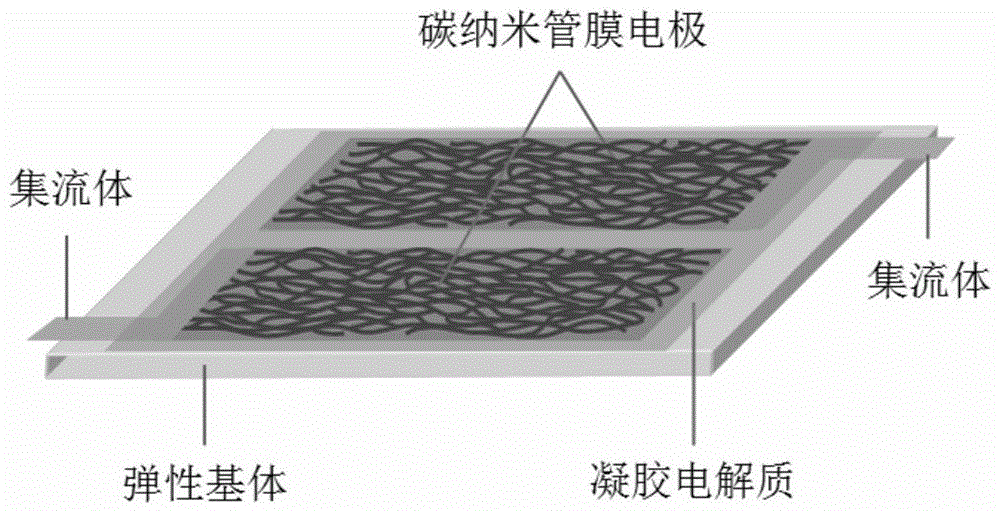

[0061] By adopting the invention, a bidirectional stretchable supercapacitor with a sandwich sandwich structure is prepared.

[0062] The preparation methods of carbon nanotube film, elastic matrix and gel electrolyte are the same as in Example 1. The thickness of the carbon nanotube film is 100nm, and the thickness of the PDMS substrate is 0.5mm. The specific steps are: use the carbon nanotube film as an electrode, spread it evenly on the elastic substrate, connect the current collector with a conductive material at one end of the electrode, and evenly coat a layer of gel electrolyte on the surface; repeat the above steps; The tube film is stacked on top of each other, and the gel electrolyte between the two electrode films is combined with light pressure. A certain distance is kept between the two electrodes, and the two-way stretchable supercapacitor with a sandwich sandwich structure is prepared by standing at room temperature for 48 hours. The thickness of the gel electr...

Embodiment 3

[0064] The experimental method and steps are the same as those in Example 1, except that the two carbon nanotube film electrodes have a rectangular periodic structure. The specific steps are: evenly spread the carbon nanotube film on the elastic substrate, use a wooden toothpick to cut the middle of the carbon nanotube film along a rectangular broken line, and divide the carbon nanotube film into two asymmetrically conjugated comb-shaped films as two Electrode, the electrode film has 5 rectangular teeth, tooth width 2mm, tooth length 5mm, the tooth length direction is along the film width direction, and the distance between the two electrodes is 1mm. Connect one end of the two film electrodes to the copper foil as a current collector with conductive silver paste. A layer of gel electrolyte is evenly coated on the surface and between the two carbon nanotube membrane electrodes, and left to cure at room temperature for 24 hours. The thickness of the gel electrolyte layer is 45 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com