Sea urchin shaped nano-hemisphere array as well as preparation method and application thereof

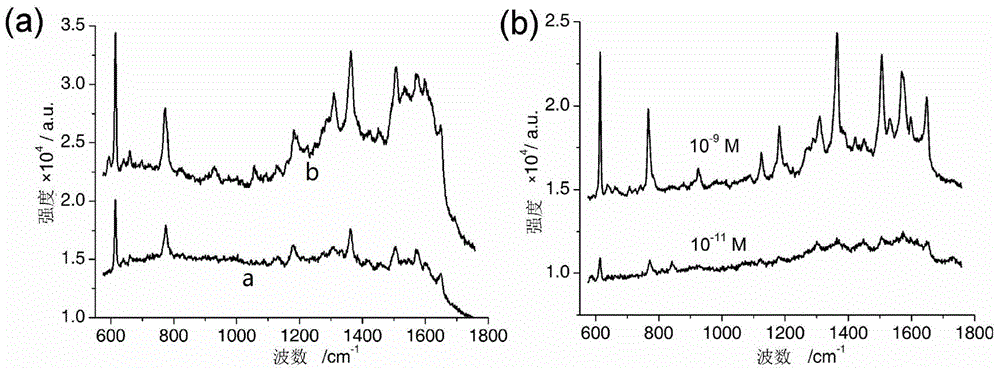

A silver nano, sea urchin-shaped technology, applied in the field of sea urchin-shaped silver nano hemisphere array and its preparation, can solve the problems of low cost performance, few layers, inaccessibility, etc., and achieves scientific preparation method, high surface roughness, and wide detection range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The concrete steps of preparation are:

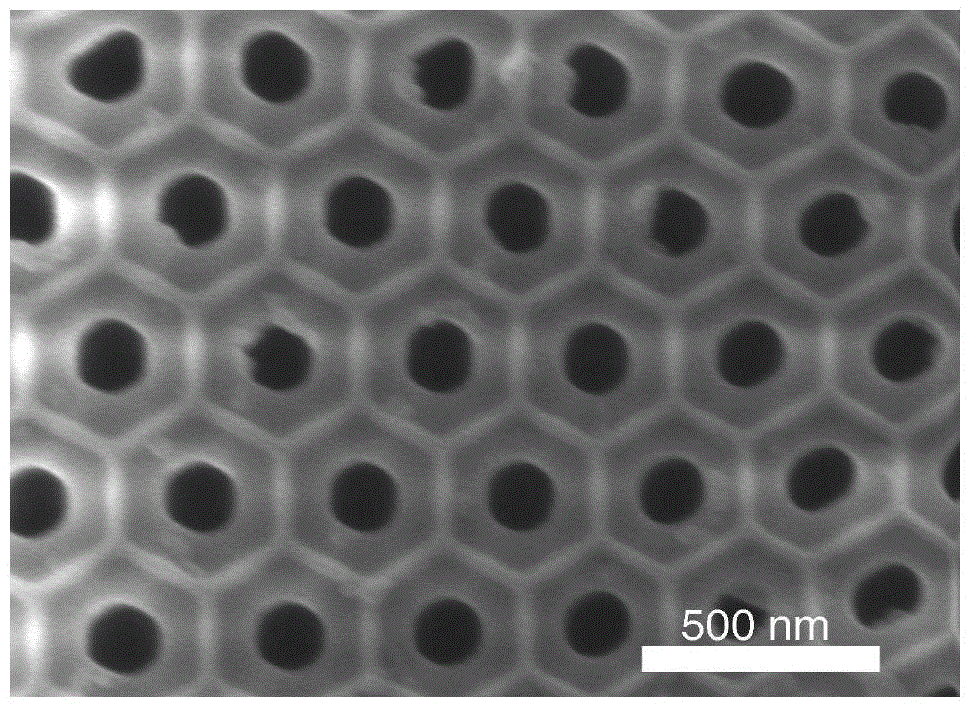

[0044] Step 1: First place the aluminum sheet in a 0.2mol / L phosphoric acid solution at -4°C, anodize it at a DC voltage of 190V for 8 minutes, and then soak it in a phosphochromic acid mixture at 50°C for 16 hours. Then, put it again under the same process conditions for the second anodic oxidation for 8 minutes, first use tin chloride solution to remove the unoxidized aluminum on the back, and then place it in 4wt% phosphoric acid solution at 45°C for 55 minutes to remove barrier layer and reaming, to obtain an approximate figure 1 A through-hole alumina template with a pore diameter of 150 nm is shown.

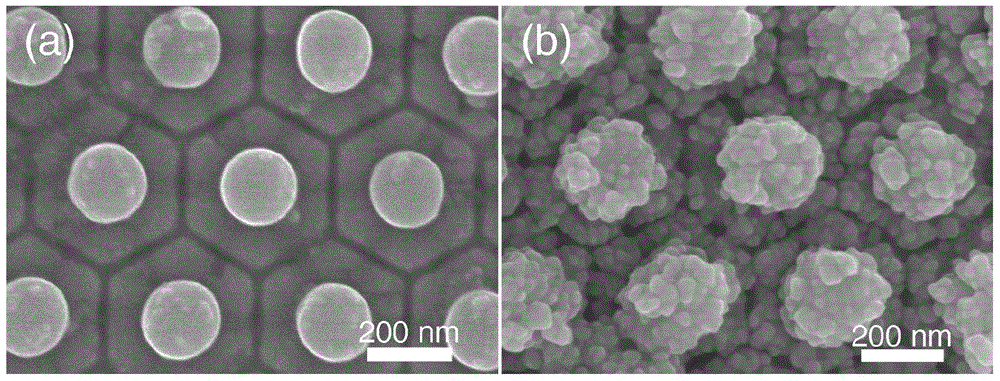

[0045] Step 2, sputtering the silver film on one side of the through-hole alumina template; wherein, the current of the sputtering silver film is 4mA, and the time is 35min, so that one side is covered with a silver film, and there is a silver film between the silver film and the orifice. An alumina template with a hexagonal...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] Step 1: First place the aluminum sheet in a 0.25mol / L phosphoric acid solution at -5°C, anodize it at a DC voltage of 193V for 7 minutes, and then soak it in a phosphochromic acid mixture at 55°C for 13.5 hours. Next, place it again under the same process conditions for the second anodic oxidation for 9.5 minutes, first remove the unoxidized aluminum on the back with a tin chloride solution, and then place it in a 4.5wt% phosphoric acid solution at 46°C 53min to remove the barrier layer and reaming, to obtain such as figure 1 A through-hole alumina template with a pore diameter of 180 nm is shown.

[0050] Step 2, the silver film is sputtered on one side of the through-hole aluminum oxide template; wherein, the current when sputtering the silver film is 4.5mA, and the time is 33min, so that one side is covered with a silver film, and the distance between the silver film and the orifice is Alumina template with silver hex...

Embodiment 3

[0053] The concrete steps of preparation are:

[0054] Step 1: First place the aluminum sheet in a 0.3mol / L phosphoric acid solution at -6°C, anodize it at a DC voltage of 195V for 6 minutes, and then soak it in a phosphochromic acid mixture at 60°C for 11 hours. Then, put it again under the same process conditions for the second anodic oxidation for 11 minutes, first use tin chloride solution to remove the unoxidized aluminum on the back, and then place it in 5wt% phosphoric acid solution at 48°C for 50 minutes to remove barrier layer and reaming, to obtain an approximate figure 1 A through-hole alumina template with a pore diameter of 200 nm is shown.

[0055] Step 2, the silver film is sputtered on one side of the through-hole alumina template; wherein, the current of the sputtering silver film is 5mA, and the time is 30min, so that one side is covered with a silver film, and the silver film and the hole are covered with a silver film. An alumina template with a hexagonal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com