Austenitic stainless steel metallography corrosion agent and austenitic stainless steel metallography display method

A technology of austenitic stainless steel and display method, applied in the field of 316L austenitic stainless steel and 316, can solve the problems of large influence of results, uneven structure corrosion, many metallographic structure contractures, etc., to achieve stability and reproducibility Good, good corrosion effect, little effect of tissue interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

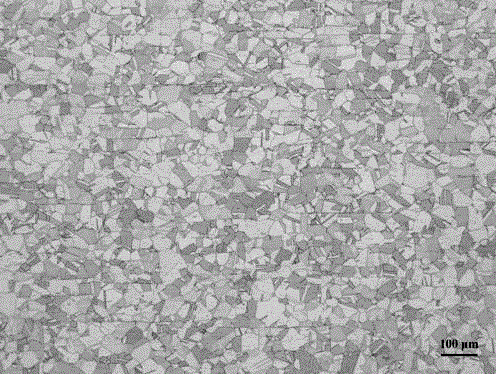

Embodiment 1

[0025] Preparation: At room temperature, sequentially pour 46.5ml of acetic acid, 93ml of hydrochloric acid, 31ml of nitric acid and 31ml of hydrofluoric acid into a plastic cup, stir with a stirring rod for 20 seconds, and let it stand for 30 minutes to prepare a corrosive agent. That is, the etchant is composed of 1 part by volume of nitric acid, 3 parts of hydrochloric acid, 1.5 parts of acetic acid, and 1 part of hydrofluoric acid.

[0026] Sample treatment: Grind the test surface of the 316L austenitic stainless steel sample with 180#, 600#, 800#, 1000#, 1200# water sandpaper in sequence, polish it to a mirror surface, then rinse it with water, spray it with absolute ethanol and dry it.

[0027] Corrosion display: Hold the polished austenitic stainless steel sample with bamboo tweezers and immerse it in the prepared metallographic etchant. Seconds, the corroded surface is preferably silver-gray. After etching, take out the sample, rinse it with water, spray it with absolu...

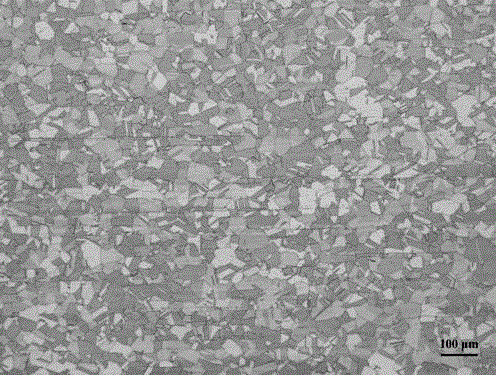

Embodiment 2

[0029] Preparation: At room temperature, pour 57ml of acetic acid, 87ml of hydrochloric acid, 29ml of nitric acid and 29ml of hydrofluoric acid into a plastic cup in sequence, stir with a stirring rod for 20 seconds, and let stand for 30 minutes to prepare a corrosive agent. That is, the etchant is composed of 1 part by volume of nitric acid, 3 parts of hydrochloric acid, about 1.97 parts of acetic acid, and 1 part of hydrofluoric acid.

[0030] Sample treatment: Grind the test surface of the 316L austenitic stainless steel sample with 180#, 600#, 800#, 1000#, 1200# water sandpaper in sequence, polish it to a mirror surface, then rinse it with water, spray it with absolute ethanol and dry it.

[0031] Corrosion display: Hold the polished austenitic stainless steel sample with bamboo tweezers and immerse it in the prepared metallographic etchant. Seconds, the corroded surface is preferably silver-gray. After etching, take out the sample, rinse it with water, spray it with absol...

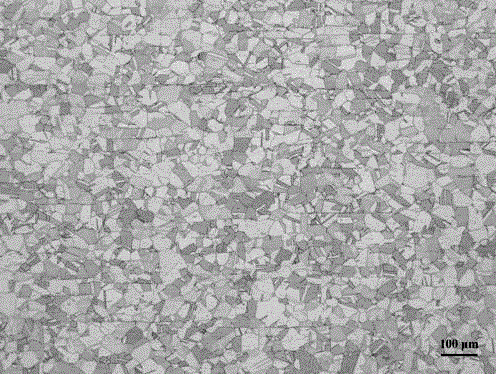

Embodiment 3

[0033] Preparation: At room temperature, pour 67ml of acetic acid, 81ml of hydrochloric acid, 27ml of nitric acid and 27ml of hydrofluoric acid into a plastic cup in turn, stir with a stirring rod for 20 seconds, and let stand for 30 minutes to prepare a corrosive agent. That is to say, the etchant consists of 1 part by volume of nitric acid, 3 parts of hydrochloric acid, about 2.48 parts of acetic acid, and 1 part of hydrofluoric acid.

[0034] Sample treatment: Grind the test surface of the 316L austenitic stainless steel sample with 180#, 600#, 800#, 1000#, 1200# water sandpaper in sequence, polish it to a mirror surface, then rinse it with water, spray it with absolute ethanol and dry it.

[0035] Corrosion display: Hold the polished austenitic stainless steel sample with bamboo tweezers and immerse it in the prepared metallographic etchant. Seconds, the corroded surface is preferably silver-gray. After etching, take out the sample, rinse it with water, spray it with absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com