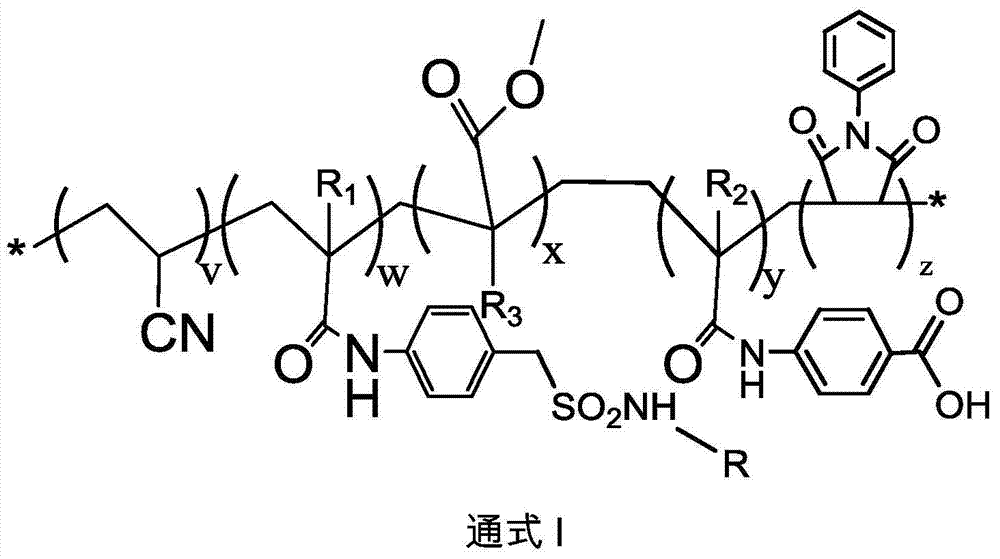

Positive-image PS-version and CTcP lithographic plate printing plate material

A lithographic printing plate and plate material technology, which is applied in the field of positive PS plates and CTcP lithographic printing plates, and can solve problems such as limitations, poor precision, and poor chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

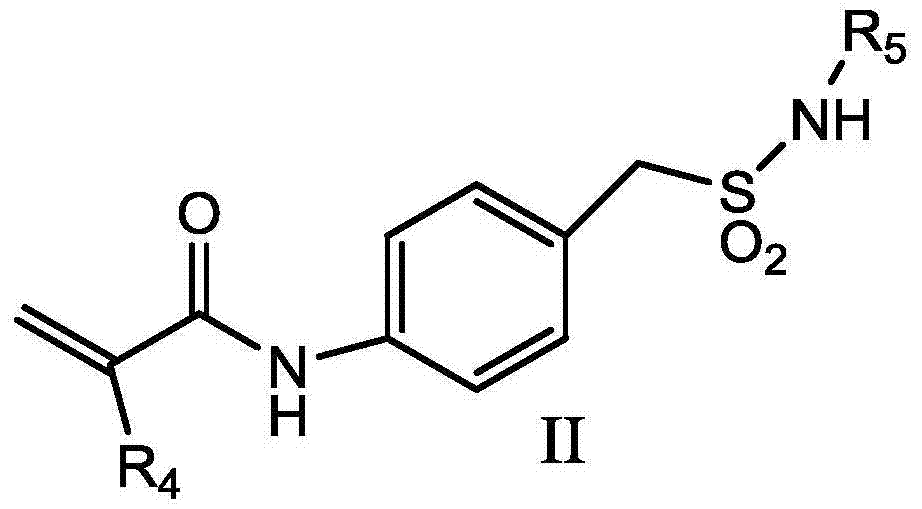

[0099] Add 31.0 g (0.36 mol) of methacrylic acid, 39.1 g (0.36 mol) of ethyl chloroformate, and 200 ml of acetonitrile into a 500 ml three-necked flask equipped with a stirring, thermometer, and constant pressure dropping funnel, and start stirring to stir the mixture. uniform. The mixture was cooled with an ice-water bath, and 36.4 g (0.36 mol) of triethylamine was added dropwise within 1 hour. After the dropwise addition, the ice-water bath was removed, and the dropping funnel was replaced with a condenser. Stirring was continued for 30 minutes at room temperature. 60.08 g (0.30 mol) of 1-(4-aminophenyl)-N-methyl-methylsulfonamide was added to the reaction mixture, and the mixture was stirred and reacted at 70° C. for 1 hour. The reaction mixture was cooled and added to 1 liter of water and stirred for 30 minutes. Then filter, beat and wash with 500ml of water, and dry to obtain 30 grams of white powdery N-[4-((N-methyl-aminosulfonyl)methyl)phenyl]-2methyl-2-acrylamide. ...

Embodiment 2

[0101] Synthesis of Acrylic Resin FSR1

[0102] In a 500ml four-necked flask, install a stirring tube, a dropping funnel, and nitrogen gas, add 105 grams of ethyl cellosolve, 0.6 g of dibenzoyl peroxide, and 15 g of the above-mentioned APDMAA, start stirring to dissolve, and add methyl Acrylic acid 11.5g, styrene 3.5g-2-hydroxyethyl methacrylate 10g, N-phenylmaleimide 5g, stirred for 10 minutes, started to heat up to 80°C, reacted for 1 hour, started to drop mixed monomers (15g of APDMAA, 11.5g of methacrylic acid, 3.5g of styrene, 10g of 2-hydroxyethyl methacrylate, 5g of N-phenylmaleimide, dissolved in 105ml of ethyl cellosolve), within 1 hour After dripping, continue to react for 4 hours. After the reaction, cool down to room temperature, add 0.5g hydroquinone (dissolved in 50ml ethyl cellosolve), stir for 10 minutes, then slowly add the reaction mixture into 4 liters of water , to obtain a white solid, filtered, cleaned three times, placed in a vacuum drying oven to dry, ...

Embodiment 3

[0104] Synthesis of Acrylic Resin FSR2

[0105]In a 500ml four-neck flask, install a stirring tube, a dropping funnel, feed nitrogen, add 105 grams of ethyl cellosolve, 0.6 g of dibenzoyl peroxide, and 15 g of the above-mentioned APDMAA, start stirring to dissolve, and add formaldehyde 13.5g of methyl acrylate, 1.5g of methacrylic acid, 10g of acrylonitrile, 5g of N-phenylmaleimide, stirred for 10 minutes, began to heat up to 80°C, reacted for 1 hour, and began to drop mixed monomers (15g of APDMAA, 13.5g of methyl methacrylate, 1.5g of methacrylic acid, 10g of acrylonitrile, 5g of N-phenylmaleimide, dissolved in 105ml of ethyl cellosolve), drop it within 1 hour Finished, continued to react for 4 hours, after the reaction finished, down to room temperature, added 0.5g hydroquinone (dissolved in 50ml ethyl cellosolve), stirred for 10 minutes, then slowly added the reaction mixture in 4 liters of water, Obtain white solid, filter, wash three times, be placed in vacuum oven and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com